- BLOG

How is a Well-Maintained Fleet Your Silent Profit Driver?

Published: January 20, 2026

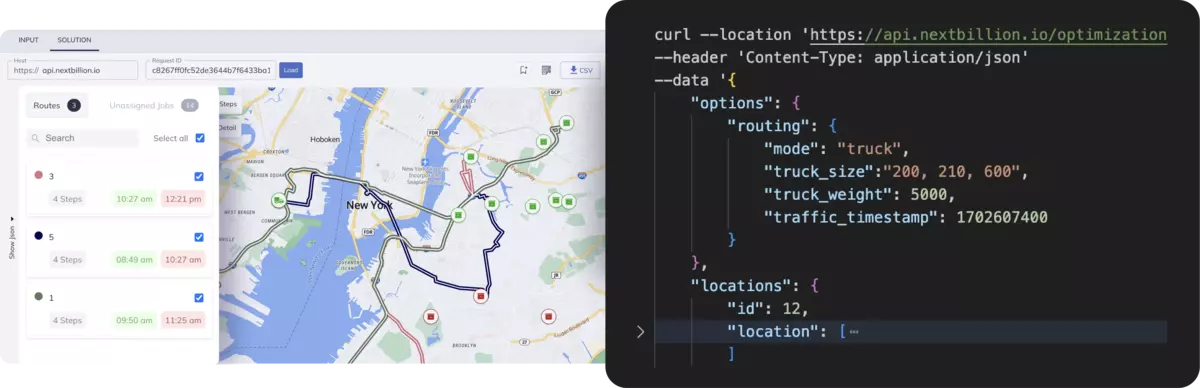

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

What if the biggest drain or boost to your fleet’s profits isn’t fuel prices, delivery volume, or market conditions, but something far quieter happening under the hood? In the fast-paced world of logistics, fleets often lose money not through dramatic failures but through silent inefficiencies that chip away at margins day after day. A well-maintained fleet doesn’t just run better, it earns better, with fewer breakdowns, lower expenses, and higher productivity. Ready to uncover how maintenance becomes a silent profit engine for your fleet? Keep reading the blog to learn more.

Did you know?

Fleet maintenance is not merely a line item in the business operation, but rather a strategic financial instrument that defines long-term profitability, competitiveness, and sustainability of any business that depends on fleets. Maintenance has an impact on all economic aspects of operations: depreciation of assets, continuity of revenues, exposure to risk, customer loyalty, and even brand equity. When handled with a smart mind, maintenance is a profit multiplier which transforms vehicles into a predictable source of profit instead of unreliable expense liabilities.

Sudden mechanical breakdowns of vehicles do not simply stop a truck; they disrupt a whole economic system. With every minute of downtime, it will trigger:

Due to the uncertainty of downtime, it generates high variance, high cost events disrupting margins.

Industry reports place the direct cost of downtime for a commercial truck at 75 to 125 dollars per hour (1.25 to 2.08 dollars per minute). This does not include lost revenue or customer churn, which often exceed the repair costs.

A distribution truck breaks down halfway to a supermarket chain.

Single breakdown cost: $1,260 and above.

Preventive maintenance could have prevented this for less than $120.

Uncontrolled stress makes fleet assets depreciate most. Preventive maintenance is lessening this process, which provides businesses with additional years of productive service and end-of-life sale value.

Proper maintenance enhances the productivity of the assets and the capital recovery.

Two identical vans attain 5 years of service:

Van A: Clean service history, in good condition.

Van B: Abnormal service, apparent mechanical abuse.

Resale values:

Difference: $4,500 in recovered capital for a single vehicle.

Across a 50-vehicle fleet, this equals $225,000 in additional resale value.

Fuel is one of the largest controllable expenses in fleet operations. Maintenance increases fuel economy as the engine, tires, and the drive train are maintained to be at their most efficient.

According to the Department of Energy:

Small percentage returns across a fleet would result in huge financial savings.

A fleet of 80 delivery vans:

The fleet saves over $70,000+ a year at just 3.50 a gallon of fuel due to increased fuel efficiency.

Properly serviced cars not only transport goods but also reliability, the basis of customer confidence and future sales.

Customers equate reliable vehicles with reliable companies.

A logistics provider raises uptime from 92% to 98% through preventive maintenance.

Maintenance served as a revenue protection and revenue expansion strategy.

“Silent losses” are the hidden costs which do not show up in the ‘Repairs & Maintenance’ line item, yet quietly take away profit due to elevated risk, wasted assets and long term damage to the equipment. By taking a fully proactive approach, fleets can find and close these leaks. Below are the deeper dives into those silent costs.

Aggressive or bad driving habits greatly speed up vehicle aging, thus incurring costs long before a part really breaks. It is often perceived as more frequent service than a maintenance failure due to this silent decline.

Although route planning is generally a logistics activity, its influence on maintenance costs is extensive and frequently ignored. The longer and inadequately selected paths demand increasingly frequent repair and change of parts.

The economic impact of a safety event is much greater than the cost of fixing the damaged car. Also, it resonates heavily in terms of court, administrative, and insurance costs in the years to come.

Ineffective inventory and asset use creates financial drag that restricts capital and labor use which is not visible in regular operating reports.

These illustrations show how minor, frequent maintenance and management failures can translate into huge, unnoticeable losses in a single year on a 50-vehicle fleet.

Silent Loss Category | Annualized Hidden Cost (Illustrative) | Calculation Example |

Driver Wear and Tear | $2,480 (10 x $200 + 10 x $240 labor) | Extra $200 per year for premature brake and tire wear on 10 vehicles, plus 2 days of labor per vehicle (8 hours at $30/hour) for unscheduled minor repairs. |

Excessive Idling | $35,000 (pure fuel waste) | 50 vehicles idling 1 hour/day for 250 days: 50 × 1 × 250 × 0.8 gallons/hour × $3.50 per gallon. |

Inefficient Routing | $40,625 (fuel, tire, fluid wear acceleration) | 50 vehicles driving 5 extra miles/day for 250 days: 50 × 5 × 250 × $0.65 operating cost per mile. |

Administrative Burden | $7,500 (lost management productivity) | Fleet manager spends 2 hours/week on paperwork: 50 weeks × 2 hours × $75/hour. |

Total Estimated Silent Loss | $85,605 | Combined loss across all categories. |

Note: (All values are approximate and intended for illustrative estimation.)

There are two giants in the world of maintenance strategies, Preventive Maintenance and Reactive Maintenance. Both of these methodologies are critical in the development of the operational philosophy of the contemporary fleets. Fundamentally, they are two contrasting worldviews, one based on anticipation and system awareness, and the other one based on waiting to fail.

Reactive maintenance is only done when a breakdown has occurred. The damage is already done by this time. Cargo halts on the highway, supply chains come to a halt, cars are repaired at inflated prices, and delivery schedules are ruined. It is a plan that is characterized by crisis management but not operational control.

Preventive maintenance (PM) is preemptive. It makes sure that vehicles are maintained in time, vital components are checked before breakdown, and problems are identified in time. Rather than combating crises, PM creates a reserve of trustworthiness around the fleet. This transformation defends uptime instead of addressing downtime, transforming maintenance into a strategic asset.

Reactive to Preventative Maintenance is not a simple operational change; it is a paradigm shift in the way a fleet is structured in addressing the risk, cost, and asset health. Although Reactive Maintenance seems to be less expensive at the moment since nothing is paid until something fails, it is just an illusion. It attributes the concealed costs of downtime, lost revenues, emergency repairs, and degradation of assets.

Preventive Maintenance on the other hand is a planned investment. It stabilizes the operating cost, secures the asset value, mitigates volatility, and provides predictability of operations. In the long run, this change has a fleet that is not only in good condition but systematically more profitable.

In simple terms:

Below is how Preventive Maintenance produces a truly well-maintained fleet:

Frequent checks of belts, fluids, tires, and brakes help technicians to determine fatigue patterns well before failure. PM transforms failures into a planned service instead of disastrous breakdowns. This safeguards delivery schedules, lessens towing accidents, prevents expensive emergency maintenance, and maintains the productivity of the drivers.

Mechanical failures follow a chain-reaction logic. A $50 hose ignored becomes a $5,000 engine failure. A worn brake pad becomes a damaged rotor. PM interrupts these chains early. By managing repairs at low costs and predictability, PM is changing the maintenance budgets from the state of being volatile and reactive to stable and optimized.

The efficiency of fuel consumption is a mechanical result. Friction and engine load are minimized by clean filters, proper tire pressure, and frequently replaced oil. In cases where the engines are working as intended, fuel is used more efficiently. Even a slight percentage increase in mileage across a fleet yields huge financial payouts, and PM is a savings generator on a daily basis.

Preventive Maintenance is a form of stress management of vehicles. New oil reduces internal friction, replacement of brakes in time preserves the rotors, and healthy fluids decreases thermal stress. In the long run, this reduces the structural wear, increases the lifespan of the components, and postpones the necessity of expensive vehicle replacements. PM transforms the lifespan of assets as an uncertainty to a variable that can be controlled.

Reactive maintenance brings about prolonged, unpredictable downtime. Preventive Maintenance makes sure that the downtime is minimal and planned. Fleets do not lose vehicles days in advance because of unexpected failures but an hour or two during planned service periods. This balances the number of vehicles and maximizes revenue generating capacity.

The state of the vehicle plays a major role in road safety. Accidents are prevented by responsive brakes, high tread tires, and working lights. PM makes sure such safety critical systems perform optimally. The outcome is improved security of the drivers, cargo, and people, and less liability on the company.

Breakdowns are one of the biggest disruptors of delivery performance. When vehicles rarely fail, fleets hit their delivery windows consistently. Meeting SLAs strengthens customer trust, improves long-term retention, and enhances the company’s reputation as a reliable service partner.

The operations of the fleet should correspond to high standards of regulation connected with safety, emissions, and roadworthiness. Preventive Maintenance is in accordance or beyond these requirements whereby all vehicles are made to be compliant. This decreases the chances of fines, citation, forced downtime, or inspection failures.

When vehicles reach retirement, their resale value is determined largely by their maintenance history. A clean and well documented PM record indicates that the asset has been taken care of in a responsible manner. The price paid by buyers increases, and the results of the auction become better, and the company receives a higher percentage of its initial investment.

Maintenance of fleets is not merely a mechanical task anymore, it is an information issue. Failure, ineffectiveness, and safety hazards do not happen because of one failed component; they come in forms of patterns: unnecessary mileage, inefficient routing, rough driving, overweight vehicles, unnecessary idle time, and blind spots in the visibility of operation. Reactive maintenance is a failure since it only considers each incident as a single event rather than seeing the system-wide state that led to the incident.

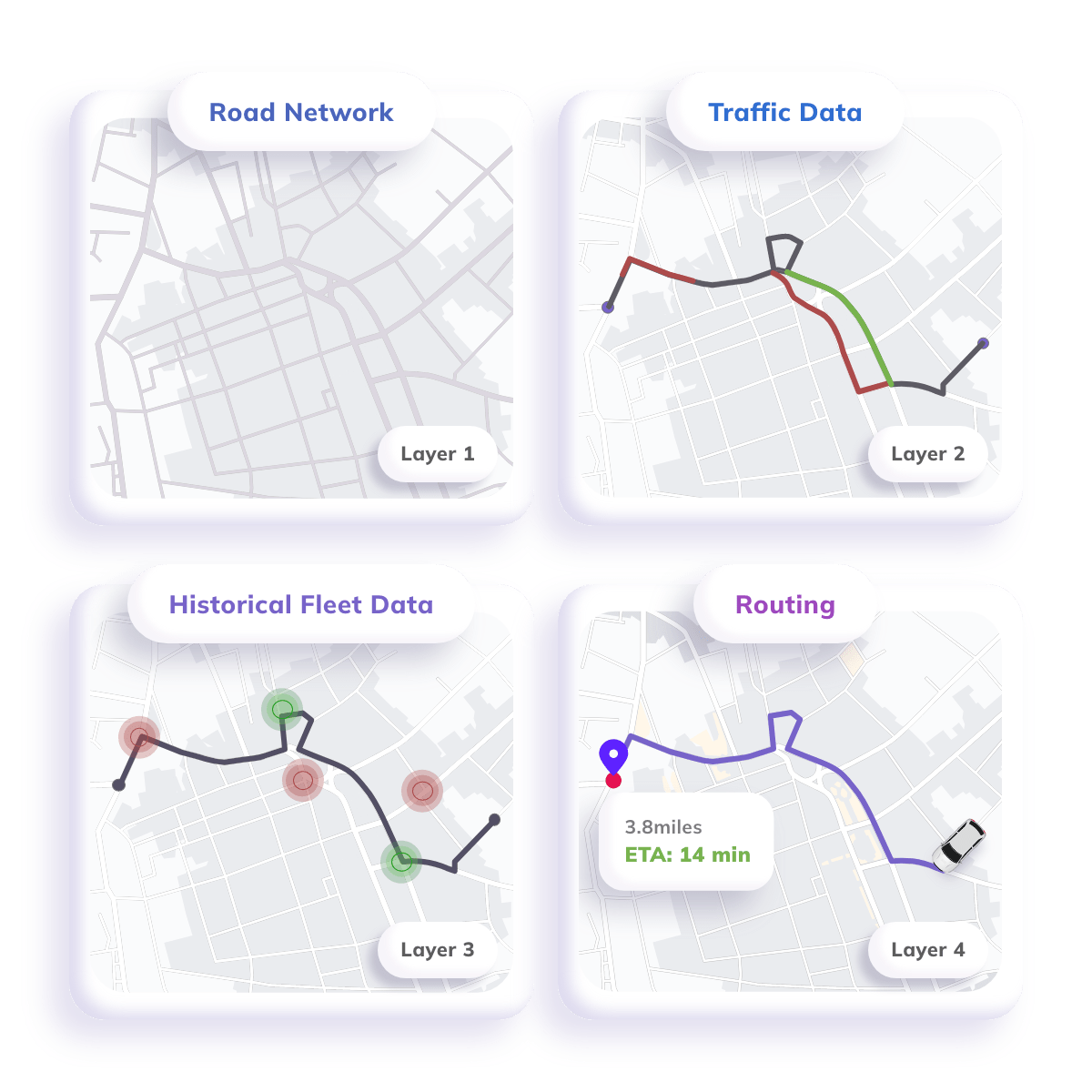

NextBillion.ai solves this by turning fleets into intelligent, self-optimizing systems.

It combines real time telemetry, spatial intelligence, algorithmic routing, and behavioral analytics to reveal the latent forces of operation which hasten wear and tear. Fleets can predict, plan, and avoid faults before they occur rather than waiting until they do.

Simply put, NextBillion.ai is the technological basis of an ecosystem of predictive maintenance, in which the risk is recognized early, vehicle use is optimized, and asset life becomes a variable to be controlled instead of a guess.

Below is a deeper conceptual look at how each component enables this transformation.

The quality of the miles covered is a key factor that determines the degradation of the vehicle, not the number. The Route Optimization API of NextBillion.ai makes sure that vehicles move in the most fuel-efficient and least harmful way.

Conceptual advantages for maintenance:

Live Tracking turns the maintenance system into a behavior-driven health model rather than a mileage-driven maintenance system; it is much more precise and economical.

Vehicle degradation is strongly influenced by the quality of the miles driven—not just the quantity.

NextBillion.ai’s Route Optimization API ensures vehicles travel through the environment in the least damaging, most fuel-efficient way possible.

Conceptual contributions to maintenance:

This shifts routing from a logistics decision to a predictive maintenance control mechanism.

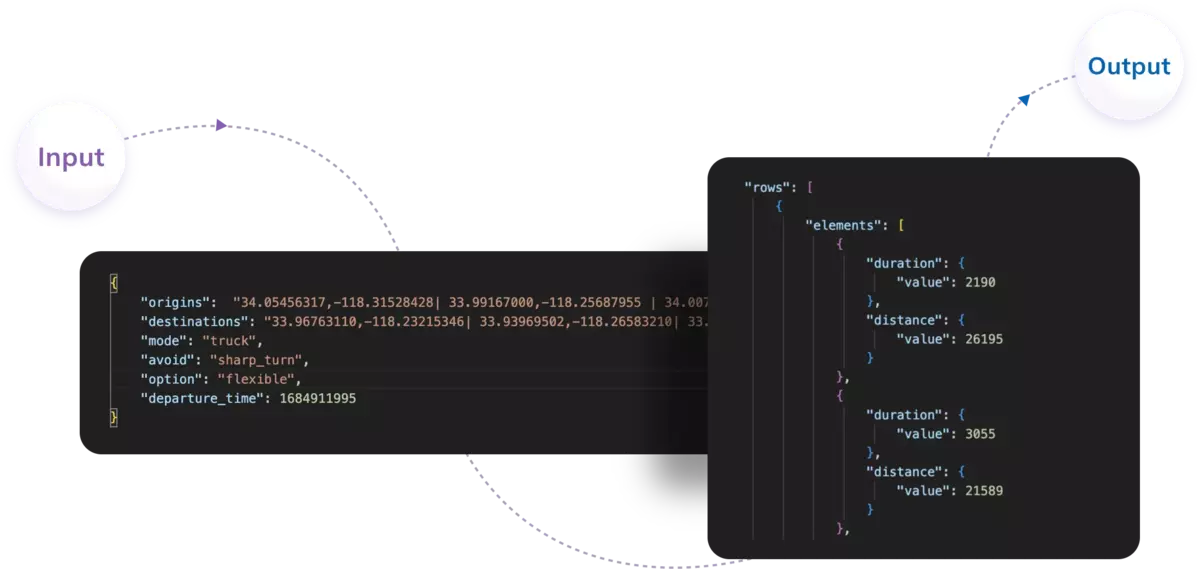

Although the routing defines the movement of vehicles, the Distance Matrix API is a model of the larger mathematical correlations between distance, time, traffic, and load of operation.

Basically, this API is supporting:

The Distance Matrix API therefore constitutes the analytical layer which converts reactive service schedules into predictive and usage-calibrated maintenance schedules.

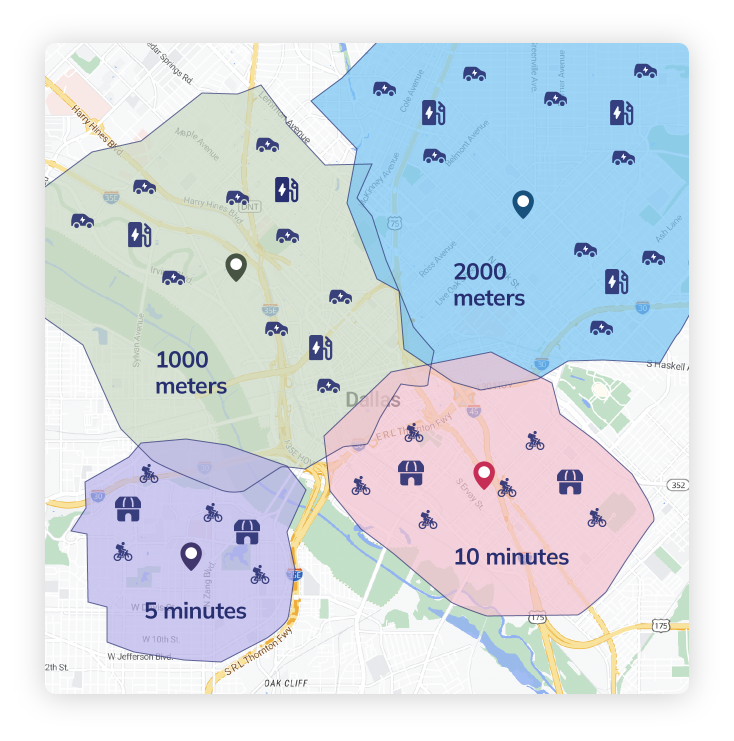

A lot of maintenance problems are not due to mechanical design but exposure to the environment, bad roads, unsafe places, overloading zones, or idle heavy logistic hubs. Geofencing API allows fleets to encode operational wisdom into spatial boundaries.

The main benefits are:

This API makes geography a predictive maintenance parameter.

Driver behavior is one of the largest hidden drivers of maintenance costs. The Navigation SDK improves not just navigation accuracy but the quality of driving.

Conceptually, the Navigation SDK enables:

Ultimately, the Navigation SDK embeds maintenance intelligence directly into the driver’s workflow, shaping behavior that extends asset life.

NextBillion.ai redefines fleet maintenance as an intelligence-driven ecosystem with many aspects, in which:

With this combination of spatial intelligence, real time data, and algorithmic optimization, a fleet environment is formed in which:

NextBillion.ai enables fleets to switch to predictive, intelligence-driven maintenance systems, which are based on forecasting instead of repairing, allowing fleets to achieve greater uptime, reduced costs, and extended asset life. Connect with us to know more.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.