- BLOG

From OMS to On-Road: How Enterprises Can Automate Delivery Planning

Published: August 12, 2025 | Updated: August 13, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

The typical enterprise loses as much as 20% of its logistics costs each year due to inefficiencies, manual route planning, and delivery errors (Inbound Logistics). If you have any responsibility for the outcomes of deliveries, you know this isn’t a hypothetical number; it’s a hard reality that we live with every day. What actually makes automated delivery planning work at enterprise scale? And how can we make our logistics run cleaner, faster, and more reliably from our OMS all the way to the customer’s front door? Read the full blog to find out.

Here are the essential elements that are making a case for fresh ideas about enterprise delivery:

Anyone managing operations or customer experience feels the heat: clients not only expect speed but also demand pinpoint accuracy, real-time visibility, and an arrival time you can set your watch to. That’s the pain in the neck e-commerce has brought. For most consumers, checking on the status of their order right after they hit the “buy” button has become a ritual. And if there’s any mismatch between what was supposedly coming and what is actually coming (or not coming), we let the world know in our reviews and social media posts.

Enterprise-scale delivery is complicated. It takes thousands of SKUs, many hubs, and several kinds of movement, to say nothing of thousands of people and tons of machinery, working together in compliance with an array of local and international regulations, to get it done. And done it must be, in service of orders that come not just from e-commerce, but also from retail and B2B channels, service that the ORD might trigger at a rate of hundreds of deliveries per hour, with each appearance of the word “it” in the following list referring to the delivery of a different sort of order:

Even with well-deserved planners and dispatchers, manual planning hits a wall quickly. Hours upon hours are spent sorting orders, leading drivers, building routes, and resolving exceptions.

To be frank, planners don’t hit a wall in accomplishing these tasks; they hit a wall when it comes to using this information to accomplish the next task, making changes to what they’ve already planned. When do we see the impact of that wall? Well, it directly impacts lower on-time delivery rates, higher cost per drop, and unhappy customers.

The fundamental facts and concepts are what count when it comes to defining automated delivery planning at the enterprise level.

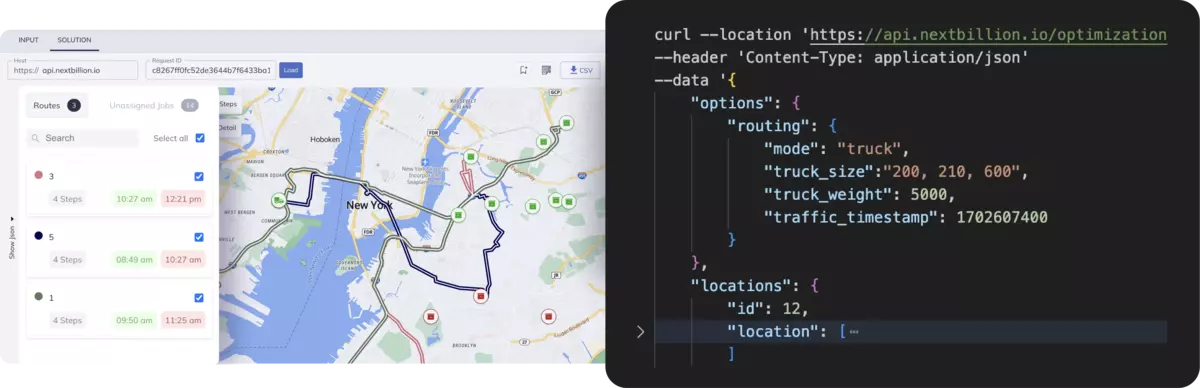

Plans for delivery that are automated mean using software and integrated systems to take orders from your OMS, apply business and operational logic, generate optimal routes, assign tasks, and keep all stakeholders informed, without the need for manual intervention at every step. Our goal is a seamless, rules-driven flow that covers order capture, validation, route building, driver allocation, real-time updates, and feedback, all within a unified digital workflow.

What you don’t connect, you can’t automate. A true automation solution that delivers in an enterprise environment is a stack of components, each one solving a core logistics problem.

Your OMS is where the process starts. For automated planning to work, direct, API-level integration is needed so that orders can be captured, validated, and sent to planning engines in real time. This setup avoids the delays and errors that can otherwise arise from manual uploading of files or email handoffs.

Today’s route engines do much more than simply sketch a line on a map. They work through millions of combinations, checking against time windows, vehicle types, local rules, and even driver schedules. And when orders change or conditions shift, the system recalculates.

The platform receives real-time data about an automobile’s whereabouts, the maintenance status of its components, and the behavior of the operator from the telematics hardware and mobile applications. When something goes wrong, it can react autonomously to the problem or inform the appropriate person. The platform even updates the people who need to know about the situation when something goes wrong.

When routes are established, the system allocates jobs to operators according to their necessary qualifications and location, as well as the vehicle’s available space. Staff send orders to the operators using digital manifesting, which is a fancy way of saying they send the necessary info to the driver using as few words as possible. This has the added benefit of reducing the number of phone calls that must occur to get everyone where they need to go.

The key phases in automated delivery planning that take an order from placement to successful delivery are these.

The Order Management System (OMS) processes every order, but not every order leaves the OMS when it is ready to go. Automated systems pull orders as soon as they are confirmed. They check for missing or conflicting information and flag any anomalies for review. This reduces last-minute delays.

The planning engine links to inventory data to verify product availability at each fulfillment node. Order prioritization considers cut-off times, service level agreements, and promised delivery slots alongside the usual first-in, first-out method.

The engine pairs each call for service with vehicles and drivers that are available at the time, examining load types, necessary licenses, customer rules that are as good as written contracts, and the windows of time in which the orders must be filled. No two orders or routes are alike, and the system considers almost every variable under the sun before it gets a plan assigned.

When a path is put together, it’s just the foundation. Data flowing in from the real world: traffic snarls, weather warnings, and so on goes back to the core, which can tell the drivers to take a different path (if they truly need to), or else just change the order of the stops they were going to make as part of the trip.

Drivers are matched with orders according to their location, skill, and workload. Compliance flags are waved where necessary, but mainly the assignment system is set to autopilot. It sends orders to drivers as if they were part of a mylar map. And there is no paper and no dispatcher on either end.

A digital manifest specifies orders, priorities, and special instructions for each driver. The whole trip is governed by turn-by-turn navigation that updates in real time if traffic changes or stops are added or removed.

Every vehicle and order status appears in real time on a dashboard for dispatchers. Customers get tracking links that show the real-time location of their driver and the ETA. These tools reduce customer inquiries about the status of their order because they close the feedback loop.

Alerts are sent via SMS and email when key milestones are reached: out for delivery, approaching, delivered. Instant photo proof of delivery and digital signatures are captured and sent to the OMS for auditing.

Here are the clearest, countable benefits enterprises get when they move from manual to automated delivery planning.

Clustering stops and sequencing routes for the least distance means fewer empty miles, less idling, and a direct reduction in fuel spend.

Automated planning enables our planners to manage a greater number of orders per shift. They deal with exceptions rather than planning the same order repeatedly. Fewer overtime hours, less administrative burden, and no more ‘overtime crisis’ mean far lower payroll costs.

Reduced time on the road, wear and tear on vehicles, and maintenance intervals add up to big savings when you’re operating at enterprise scale. And because we’re still talking about a level of automation that can handle just a little over 60% of the capacity of the average human driver, well, the human factor in all this adds a good bit of money to the equation as well.

Route planning goes from manual to automated, which can mean the difference between cutting times down from hours to minutes. Anything that’s still manual (like data entry or making subjective decisions) burns more time and more calories (in the sense of human effort), can be error-prone, and doesn’t express the full capacity of the system.

Additional bus stops along each route, additional routes each day, with no change in the bus drivers or buses available. Automation takes the same resources and uses them more effectively.

Vehicles that are not moving and drivers that are not working get spotted and sent off to other places. The platform discovers the most effective way to handle the requests, all day, every day.

Automated systems keep customers updated with real ETAs, not estimates. Alerting customers to delays, before they call or write reduces frustration and enhances the customer experience.

More orders hit promised windows because of live re-optimization and real-time issue resolution. As a result, retention and upsell are better supported.

Customers require authority and clarity. Instant notifications, confirmation of receipt, and feedback collection all proffer a better experience.

Orders do not slow down automated planning. Peak demand or new areas are dealt with by the same system, which is the essence of scalability.

Include additional service regions, modify your plan for supply chain changes, or react to unexpected events, all without having to redesign your plan by hand or wait for it to be rerouted.

Each order, route, delay, and exception is tracked by the system. KPI instant access: on-time delivery rate, cost per drop, driver performance.

Analytics enable teams to see what keeps happening: starts that happen after the timer has begun, routes that plod along in the wrong direction, and estimated times of arrival (ETAs) that are missed so often they should be re-labeled “not even close.” And then analytics help teams figure out how to fix these fixes so that they don’t keep happening in the next cycle. And the next.

Below are listed the direct solutions to the most common roadblocks encountered by enterprises in automating delivery planning.

Most businesses still operate their essential functions on outdated OMS and ERP software. For any sort of automation to work, in these places, you need core APIs that translate between old data models and the new engines of business.

Without those APIs, you can use middleware to translate, i.e., to normalize data so that it has a common format. The middleware must also support bidirectional sync—that is, it must ensure that all the systems involved in the core business are speaking the same language.

The strength of automation hinges on the caliber of your data sources. Inconsistent formats, missing product details, or incomplete orders will weaken the automated flows. When ingesting data, set up strict validation. Ensure that standard templates are used for order data, addresses, and inventory. When planning, use APIs for address verification and geocoding to catch mistakes.

Planning becomes unplanned when old systems and processes fall away. Resistance from dispatchers, drivers, and warehouse teams is common, especially when moving to a fully automated planning system. Offer training that’s not just hands-off but hands-on. Create job aids that help teams understand when to use the manual system and when to switch to an automated system. For the first few weeks, let teams run both systems simultaneously.

When managing hundreds of stops, many kinds of vehicles, and strict constraints like time windows that have to be met or the kinds of skills that vehicles must have, basic route engines just can’t cut it.

Enterprises need algorithms built for the kinds of large, dynamic fleets that are more and more common today. Solvers that were built yesterday handle the scale but can’t adapt to live data or live routing. New AI-based solvers handle both the scale and the adaptation, but still work for cost, SLA, and customer preference optimizations.

Here are practical directives that produce effects and elude typical missteps:

Establish objectives at the outset. Are you focusing on expense per delivery, timely delivery quotient, or time from order to door? Ensure that all stakeholders comprehend the target metric.

Don’t attempt to automate everything all at once. Initiate the process in a region of high impact or within a single business unit. Demonstrate the value of automation, resolve any issues that arise, and only after achieving tangible results should you consider scaling up the effort.

Prior to launch, conduct audits of your data. Ensure that your address lists, order templates, and product catalogs are free of errors. Test your data pipelines with actual examples to confirm that they are functioning properly.

Make planning a top priority, and ensure the solutions you choose have mature, well-documented APIs that integrate directly into your OMS, ERP, and telematics stack, with no need for fragile workarounds.

Instruct all the roles impacted—dispatchers, drivers, supervisors—on the new workflows and platforms. Make support accessible and feedback loops quick.

The main trends that shape delivery planning in the next years are the following.

Demand, weather, and inventory surges are predicted by AI models that analyze several years’ worth of order data along with external influencers. Enterprises use this information to preemptively place stock and make driver adjustments, and to problem-solve in general, before various kinds of problems actually happen.

Pricing adjustments, delivery slot premiums, and service downgrade recommendations can all come from algorithms. Their magic works by the rules of supply, demand, and satisfactory stylings: real-time data, historical performance, and customer contentment are all factored in.

Soon, we will require direct integration of OMS and planning engines with autonomous fleets, robots, and drones. Automated systems allocate orders to the right channel: driver, robot, or drone based on order size, SLA, and local laws.

More than just an ETA is expected by customers. Tomorrow’s systems remember what customers prefer, adjust the kind of notifications they send, and allow for the kind of self-service rescheduling that turns an inconvenient delivery into an easily managed one. These capabilities position an organization to better use delivery as a competitive advantage.

There is pressure on companies to report and reduce their carbon footprint. Automated planning systems help by tracking emissions, suggesting greener routes, and shifting loads to EVs or low-emission vehicles.

Nextbillion.ai provides automation of the enterprise-grade kind at every step of the delivery process.

Automating delivery planning is not about chasing the latest trendy term or hoping for a silver bullet. It’s about building a setup where your OMS, your planning, your tracking, and your people actually work together: less manual work, less firefighting, more deliveries that land on time. If you want numbers to move and bottlenecks to shrink, you need tools that are proven, flexible, and built for scale. That’s exactly what Nextbillion delivers, no unnecessary drama, no hype, just automation that fits your real-world needs and gets your delivery operation running the way it should.

An order management system (OMS) manages inventory, orders, and customer data. An order planning system takes this data and applies routing and operational rules to manage the execution of the actual order deliveries. An OMS handles “what and when.” An order planning system handles “how and who.”

Typically, most enterprises get their initial pilots live within a time frame of 6 to 12 weeks. This period largely depends on the quality of the data and the need for integration. A pilot that has achieved operational success then sets the stage for the next step, which is typically a regional or divisional rollout. Those rollouts can vary quite a bit, depending on either needing a fair amount of custom code written to handle legacy systems or on the amount of test and turn time being used to ensure quality.

Cost reductions seen by enterprises typically range from 10% to 25% in logistics spending, with order-to-door times getting in faster and on-time delivery rates showing real improvement. Payback periods on these expenses often stretch from 6 to 18 months, and they correlate closely with the volume of orders that a firm places and how many of its processes are still manual.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.