- BLOG

Vehicle Height and Weight Aware Routing

Published: December 16, 2025 | Updated: December 22, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

Have you ever wondered why a route that looks perfect on a map can become a costly mistake for a tall or heavy vehicle on the road? Vehicle Height and Weight Aware Routing addresses this particular challenge by making sure that trucks use routes that are within their physical dimensions and load properties. As modern fleets face increasing pressure to move goods safely, efficiently, and compliantly, understanding how routing systems account for bridge clearances, weight limits, and structural restrictions has become essential.

With the growing pressure on modern fleets to transport goods safely, efficiently, and compliantly, it has become imperative to understand how routing systems account for bridge clearances, weight limits, and structural constraints. This blog discusses the basics, issues, and components of the system, and the real world use of height and weight aware routing, enabling you to discover why smarter mapping results in safer and more reliable operations. Let us learn more:

Did you know?

Height and Weight Aware Truck Routing is an advanced navigation technology that takes into account the physical dimensions of a truck, height, width, length, axle constraints, and total weight, and then compiles a route. It does not use generic logic of the fastest path but examines road structures and legal restrictions to make sure that the vehicle can legally pass through all of the segments. This helps avoid the expensive accidents due to low bridges, weak pavements, narrow tunnels, or overweight offenses and makes the journey safe, compliant, and predictable.

Scenario

Consider a delivery truck that is operating in a region and is filled with a full trailer of a distribution center. An ordinary navigation system may lead the driver on a shortcut that goes under a low-clearance bridge and over a road that has a strict tonnage restriction. Through height and weight conscious routing, the system identifies these constraints at the earliest stage and re-calculates the route to take the truck through a safe and legal route, keeping the truck on a route that is both passable and legal.

This is particularly important when trucks are carrying cargo in new areas or in narrow urban areas, where the allowance of routing error is very narrow and the stakes are very high, e.g.:

Here are the biggest challenges in Height and Weight Based Routing:

Among the biggest challenges in the design of height- and weight-sensitive routes is the need to properly consider structural constraints. Arched tunnels, bridges with low clearance, and narrow underpasses can easily turn into serious dangers to high or oversized vehicles. Any miscalculation of a few inches can cause serious accidents, destruction of property, and expensive traffic inconveniences. The routing systems should therefore have accurate, tested information regarding the height of structures, shapes, and approach geometry to avoid unsafe routing decisions.

Numerous roads have weight restrictions depending on the strength of the pavement, the load carrying capability of bridges, or the seasonal susceptibility, e.g. thawing roads are weaker structurally and prone to weight. These dynamic tonnage limits have to be interpreted by a routing engine to ensure that the trucks are not taken on the routes in which they are legally not allowed to pass. Otherwise, there is a risk of enforcement penalties, substandard road integrity, or detours, which may delay fleet schedules and raise operating expenses.

Height and weight conscious routing relies on massive roadway, structural, and regulatory data. This information is however usually gathered by various agencies and sources and therefore leads to inconsistencies. Duplicate records, omissions, different measurement units, and fragmented formats may decrease the accuracy of the routes. This data needs to be cleaned, validated, and harmonized in order to generate credible navigation intelligence.

Inaccurately maintained map information is a direct safety hazard to road users and drivers. Wrong clearance heights, old signage information, or poor road geometry can cause trucks to get into dangerous scenarios. In height- and weight-sensitive routing, minor errors in data have been magnified. Quality, field tested inputs are thus very important in ensuring safety and confidence in routing outputs.

Road networks are constantly changing. New routes, temporary routes, weight limits, and infrastructural improvements all affect the appropriateness of a truck’s route. The routing systems can lead to vehicles using unsuitable routes when the roadway information is old. The active maintenance of maps, continuous updates, and active monitoring will assist in ensuring that routing decisions are based on the most recent conditions.

A strong routing system is based on high-accuracy and granular data. These are the width of the lanes, slope angles, overhead clearances, bridge load capacity, and the size of the tunnels. Verified data means that the route computations are based on the reality of the situation and not the estimation that might endanger the safety of the vehicles.

Each fleet is unique and even vehicles in the same fleet might differ in terms of height, weight, axle arrangement, or load distribution. Vehicle profiles are configurable to enable routing engines to make tailored recommendations to the specifications of each truck. This makes sure that the physical features of the car and the physical features of the road are compatible.

The average routing is based on speed or distance, whereas the height- and weight-aware routing is based on feasibility and safety. Algorithms should analyze low bridges, weight restrictions, turning radii, dangerous sections, and infrastructure strains. The fleets minimize operational risks by operating on safe routes and prevent paths that may damage the vehicle or cargo.

Timely and clear warnings help drivers to avoid the dangers that they might not be aware of, particularly in busy cities where the road geometry is rapidly changing. These systems identify when a truck is coming to a low bridge or a limited tunnel and give direct instructions to avoid it in real time, avoiding the accidents that are hard to undo once the driver is on the road.

A good routing platform should be able to intelligently divert vehicles around weight-restricted routes and maintain detours. This requires understanding load regulations at a granular level, whether based on gross vehicle weight, axle load, or time-based restrictions, and producing compliant, practical alternatives.

Weather conditions, construction areas, traffic jams, and temporary blocks can alter the suitability of routes instantly. The integration of real-time data allows routing systems to adapt dynamically, ensuring that trucks continuously follow safe and accessible paths throughout the journey.

Contemporary fleets are operated on the basis of telematics to track, diagnose, and provide compliance reports. With the routing systems being fully integrated with the telematics platforms, the operations teams gain real-time visibility on the vehicle behavior, deviation alerts, and route performance. This synergy assists fleets to keep safe, maximize use, and react swiftly to unforeseen circumstances.

Here are the most pivotal benefits of vehicle height and weight-aware routing:

When routing decisions account for vehicle dimensions and load characteristics, the likelihood of a truck completing its journey without interruptions increases dramatically. Height and weight conscious routing rules out routes that may be physically inaccessible to the vehicle, e.g. routes with low bridges, narrow lanes, or routes with weight constraints. This makes sure that the planned routes are not only theoretically feasible, but also practically implementable. It results in increasing the on-time delivery rates and minimizing costly diversion along the route.

One of the most common but costly accidents in the commercial trucking industry is bridge strikes. Routing systems save fleets against disastrous accidents, infrastructure damage, lawsuits, and public criticism by taking the initiative to avoid low-clearance structures. Moreover, by keeping weight limits, fines, citations, and being forced offloaded at enforcement checkpoints are avoided. Such a compliance-oriented strategy enhances integrity in the operations and protects the reputation of the fleet.

The path that seems to be short is not necessarily the fastest one, particularly to large trucks which have structural limitations. Height and weight aware routing identifies unsuitable paths early in the planning phase, preventing drivers from encountering dead ends or restricted segments that require time-consuming detours. By removing these sources of friction at the front end, fleets are able to keep their travel times predictable, less idle time, and simplify the process of scheduling downstream operations.

The economy of fuel is not only determined by driving habits but also the quality of the routes. Steep grades, stop and go detours, and circuitous reroutes should be avoided as much as possible to reduce unnecessary fuel consumption. By always taking into account the nature of vehicles, routing logic can make better forecasts of fuel, which allows better budgeting, less wastage, and decision-making based on load capacities and the batches of delivery.

The drivers are very dependent on routing systems to guide them, especially in new territories or in city congestions. When directions consistently avoid unsafe or non-compliant paths, driver trust naturally increases. When drivers are confident, they will be less stressed, make fewer mistakes, and can concentrate on how to deliver safely instead of doubting their navigation devices. Such morale boost is also usually translated into increased productivity and decreased turnover throughout the fleet.

Here are the use cases of vehicle and vehicle height and weight aware routing:

The long-haul freight vehicles move in the states and regions with the different roadway structures. Height and weight conscious routing are used to ensure that these vehicles do not go over low bridges, narrow highways, or unstable rural roads, which were never designed to carry the large commercial loads. In the case of cross country and interstate business, this routing accuracy has a great reduction in risk and a guaranteed delivery performance.

The city and state agencies have fleets that transport construction machines, snow removal machines, garbage bins, and other heavy machinery. Such vehicles often go beyond the normal weight and size specifications. Smart routing allows cities to observe the local infrastructure constraints, minimize the road wear, and ensure that the civic regulations are adhered to, particularly when passing through residential areas or the outdated urban infrastructure.

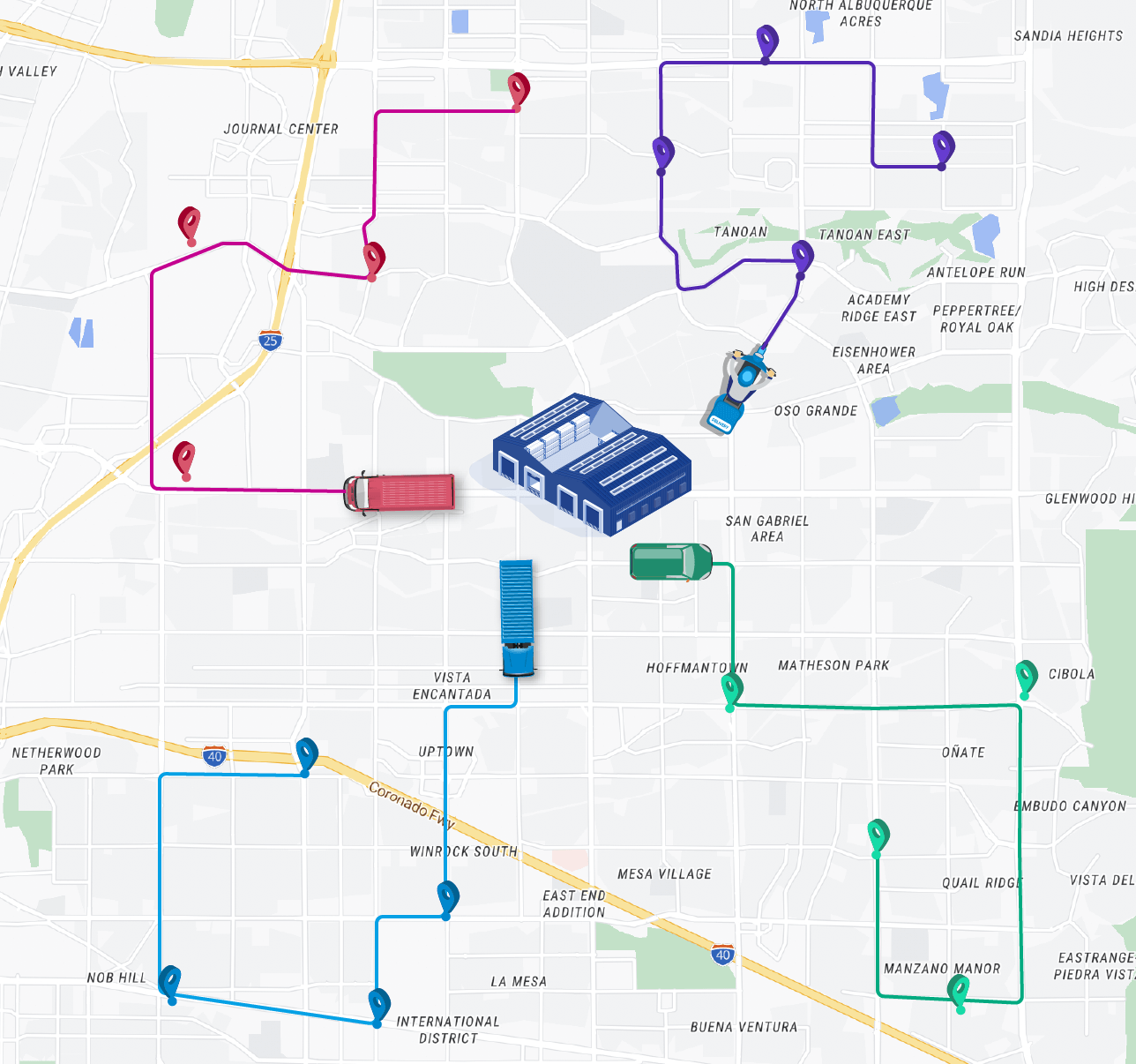

The large logistics companies usually deal with a variety of fleets including vans, high-roof trucks, box trucks, and semi-trailers. Routing that fits all sizes does not work in these environments. Height and weight aware routing is a dynamic routing that takes into account the paths of each vehicle profile and makes sure that the full fleet is optimally utilized. This results in better allocation of loads, reduced route interruptions, and coordination among vehicles of different sizes.

Other sectors such as the heavy engineering sector, the energy sector, and manufacturing often ship bulky products such as turbines, industrial parts, or prefabricated structures. These loads are often more than the normal roadway limits and need very accurate routing. Height and weight awareness aids in establishing safe corridors, escort requirements, structural bottlenecks, and regulatory compliance steps, and is thus an essential tool to the specialized transport operators.

The telecom, electricity, gas, and municipal service vehicles are frequently deployed in urban settings that are densely populated with infrastructure. Such vehicles can have tall equipment or work around low cables, limited tunnels, and narrow service roads. Smart routing will make sure that they can reach work sites without any harm, do not have to struggle with structural constraints, and continue to provide services, especially in response to emergencies or during peak operational hours.

Weight-aware routing is a systematic task which needs precise information, vehicle modeling, and a route planning engine that can comprehend regulatory restrictions. Here’s how to do it step-by-step:

An efficient routing system is started with quality map data. This consists of bridge load ratings, axle based weight limits, seasonal tonnage regulations, weak pavement sections and temporary closures.

Any mistakes in these datasets may lead to insecure routing decisions and thus these datasets must be carefully validated.

The trucks are supposed to be represented by a complete vehicle profile that includes the gross weight, axle distribution, cargo capacity, body type, and operational limitations.

These specs make the routing engine know not only the total weight of the vehicle, but the dynamics of the weight on the road.

The routing algorithms study all road segments to ensure that they adhere to weight rules and then suggest a route.

They do not use bridges with tonnage limits, roads too weak, overweight areas, and areas that cannot support heavy loads, this makes the route secure even before the vehicle is set in motion.

A static route can be invalidated by temporary restrictions, new construction areas, and emergency closures.

The real-time updates ensure that the truck is constantly on the path of safest and most compliant direction during the trip.

It is important that there is operational visibility. Deviation alerts, trip monitoring, load compliance check, and automated record-keeping to audit are some of the powerful tools that fleet managers can gain when routing is combined with telematics.

By following these structured steps, fleets can build routing intelligence that is safe, compliant, and deeply aligned with real-world vehicle constraints, such as:

Before weight-aware routing can operate correctly, the truck itself must be loaded properly. Even a truck that is legal in terms of gross weight can be a misloaded truck, causing an overweight vehicle to exceed the axle capacity or fail to qualify as a route. This is where cargo route optimization is a mission critical aspect of weight-aware routing, since inappropriate loading can nullify even the smartest routing engine.

To make sure that the route is safe, compliant, and in line with the actual weight distribution of the truck, fleets must:

Nextbillion.ai is key to bringing height and weight awareness routing to the next level of compliance requirements, enabling a smart, scalable, and thoroughly reliable operation. Nextbillion.ai enables fleets to operate safely in the environment where every inch of clearance and every pound of load counts by enabling it to combine high precision map intelligence with configurable routing engines. Here is how the platform guarantees accuracy, consistency, and operational excellence:

At the core of Nextbillion.ai’s routing engine are meticulously curated attributes that define bridge heights, tunnel dimensions, weight restrictions, axle-based constraints, and structural load capacities.

Instead of simply avoiding “problem areas,” the system understands the exact relationship between vehicle dimensions and roadway limits. This enables highly refined route calculations that keep trucks within safe operational boundaries, whether the challenge is a low bridge in a busy city or a tonnage-restricted rural crossing.

No two fleets and often no two trucks within the same fleet are identical. Nextbillion.ai allows operators to configure detailed truck profiles that capture:

This precision ensures the routing engine builds paths around the real-world characteristics of each vehicle, not generic assumptions. The result is safer navigation and significantly reduced risk of structural conflicts.

Nextbillion.ai’s maps undergo ongoing validation cycles that incorporate field feedback, telematics signals, external datasets, and manual verifications.

This creates a map environment that is:

In height and weight sensitive routing, this high-quality map backbone is what prevents the most common and costly routing failures.

Nextbillion.ai’s APIs are built for both agility and enterprise-level expansion. Organizations can embed height and weight logic into:

The APIs provide consistency across applications, enabling teams to build custom routing logic, dynamic dispatch tools, or real-time monitoring systems without sacrificing performance or precision.

Beyond routing APIs, Nextbillion.ai offers dashboards that give operations teams visibility into how and why certain routes were chosen.

These dashboards can highlight:

This creates a shared operational picture that helps teams refine fleet policies, train drivers, and continually improve route safety standards.

Nextbillion.ai’s routing solutions are already powering thousands of fleet movements across industries where safety and compliance are non-negotiable. From long-haul trucking companies to urban delivery fleets and heavy transport operators, organizations report measurable improvements in:

This track record demonstrates that height and weight aware routing isn’t just a feature, it’s a mission-critical capability, and Nextbillion.ai provides the ecosystem to implement it at scale.

Height and weight aware routing is a pre-requisite to safe, compliant and efficient fleet operations. With the right vehicle profiling and trustworthy, constraint-sensitive map intelligence, fleets can skillfully cut risks by a significant margin, avoid unnecessary routes that cost a lot, and enhance the consistency of deliveries.

Nextbillion.ai is one of the most promising solutions that allow making this transformation at scale by means of accurate data, robust APIs, and constant validation. With the increased complexity of the road networks and the increasingly stricter regulations, the use of intelligent routing tools becomes vital to any operation that involves heavy, tall, or specialized vehicles. Ready to make your fleet safer, smarter, and fully compliance-aware? Explore Nextbillion.ai’s advanced routing solutions to unlock precise, height- and weight-aware navigation for every vehicle in your network.

The majority of the consumer navigation devices are focused on speed, rather than safety in large commercial vehicles. They do not respect such industrial constraints as hazardous-material zones, low-emission limits, or axle-based limits, so they cannot be used to provide fleet-grade routing intelligence.

The current logistics networks are working in dynamic environments. High-fidelity mapping is necessary due to frequent updates, including new construction, new road classifications, and changes in city planning resulting in uninterrupted operations that are compliant.

Digital twin technology enhances height and weight aware routing by creating a virtual replica of real-world roads, structures, and vehicle behavior. Fleets can simulate bridge clearances, axle loads, turning radii, and infrastructure stress before a truck begins its journey. This predictive modeling helps identify risks early, optimize safe routes, and ensure full compliance with height, weight, and structural regulations.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.