Table of Contents

It should come as no surprise that retail operations face ever-increasing pressure to streamline their supply chains to meet growing demand while maintaining profitability. Though often overlooked by those outside the industry, the middle mile of the retail supply chain is where most of the magic happens — inbound logistics, outbound logistics, consolidation, sorting, inventory management… there’s a lot going on. And the complexity of the supply chain only continues to grow alongside the rapidly expanding use of third-party logistics providers in retail middle-mile activities. These factors make the middle mile a prime area of focus for optimization of efficiency and cost.

Unlike the first mile (from manufacturer to distribution center) and last mile (from fulfillment center to customer), the middle mile is typically characterized by longer distances and complex routing, which poses unique challenges for retail businesses.

Challenges in Retail Middle-Mile Logistics

Some of the common challenges that retail organizations face in middle-mile logistics include:

Routing Efficiency – Determining the most efficient routes and modes of transportation to minimize transit times and costs is essential for operational efficiency.

Fragmented Transportation Networks – Coordinating multiple carriers and modes of transportation can lead to poor visibility, process inefficiencies and higher costs.

Demand Variability – Fluctuations in demand require agile logistics solutions that can scale up or down as needed to avoid bottlenecks or underutilization of resources and assets.

Inventory Management – Ensuring accurate inventory visibility and tracking becomes crucial during transit to prevent stockouts or overstock situations.

Sustainability/ESG Goals – A poorly optimized middle mile results in unnecessary miles driven, excessive vehicle idling and expired goods that must then be disposed of.

How to Optimize the Middle Mile in Retail

Let’s take a look at some of the strategies and actions that can be taken to overcome common challenges and optimize the middle mile for improved efficiency and cost reduction:

Route Optimization Tools – Utilize advanced routing software and algorithms to automate scheduling and identify the most efficient routes for transporting goods between distribution centers, fulfillment centers and local delivery hubs. A good routing solution considers factors such as distance, traffic patterns, delivery windows and custom operational requirements to minimize transit times and fuel consumption.

Consolidation of Shipments – Consolidate multiple shipments into fewer, larger loads to maximize truck capacity utilization and reduce transportation costs. By combining shipments destined for the same region or area, retailers can reduce empty backhauls and eliminate unnecessary trips wherever possible.

Collaborative Partnerships – Forge strategic partnerships with carriers, freight forwarders and logistics providers to access and leverage their specialized expertise and resources. Collaborative partnerships enable retailers to make use of shared transportation networks, negotiate favorable rates and optimize load planning for mutual benefit.

Data Sharing – Speaking of collaborative partnerships, data and visibility are key to unlocking efficiency and overcoming obstacles that result from the involvement of multiple parties. It’s important to collect, aggregate and share data at every step along the supply chain, including manufacturers, merchants and third-party logistics providers, as distribution networks become more intricate.

Real-Time Tracking – Implement tracking technologies such as GPS or RFID to monitor the location and status of shipments in real time. Enhanced visibility into the supply chain enables retail organizations to proactively address issues, minimize delays and improve customer service. Real-time tracking also helps optimize routing and scheduling for greater efficiency.

Inventory Management – Invest in inventory management systems that provide accurate visibility and control over inventory levels throughout the supply chain. By optimizing inventory allocation and replenishment processes, retail businesses can reduce stockouts, minimize excess inventory holding costs and maximize overall supply chain efficiency.

Cross-Docking Facilities – Strategically located cross-docking facilities near distribution centers or major transportation hubs can help streamline the transfer of goods between inbound and outbound trucks. Cross-docking minimizes storage and handling costs, reduces transit times and enhances the flow of goods through the supply chain.

Investment in Technology – Embrace advanced technologies such as predictive analytics, artificial intelligence, machine learning and robotics to optimize middle-mile logistics operations. These technologies enable higher demand forecasting accuracy, better resource allocation, proactive vehicle maintenance, warehouse automation and more for greater process efficiency across the board.

Continuous Improvement – Establish a culture of continuous improvement within the organization, encouraging employees to identify opportunities for optimization and implement innovative solutions. Regularly review and refine logistics processes, benchmark performance against industry standards and seek feedback from customers and partners to drive ongoing improvements.

Implement these tips, and an improvement in middle-mile efficiency is virtually guaranteed.

Optimizing the Middle Mile With NextBillion.ai

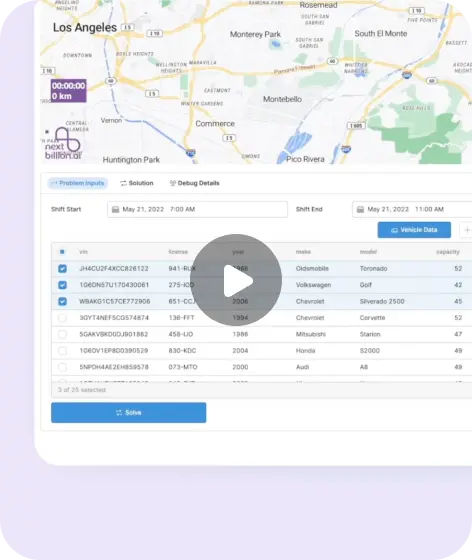

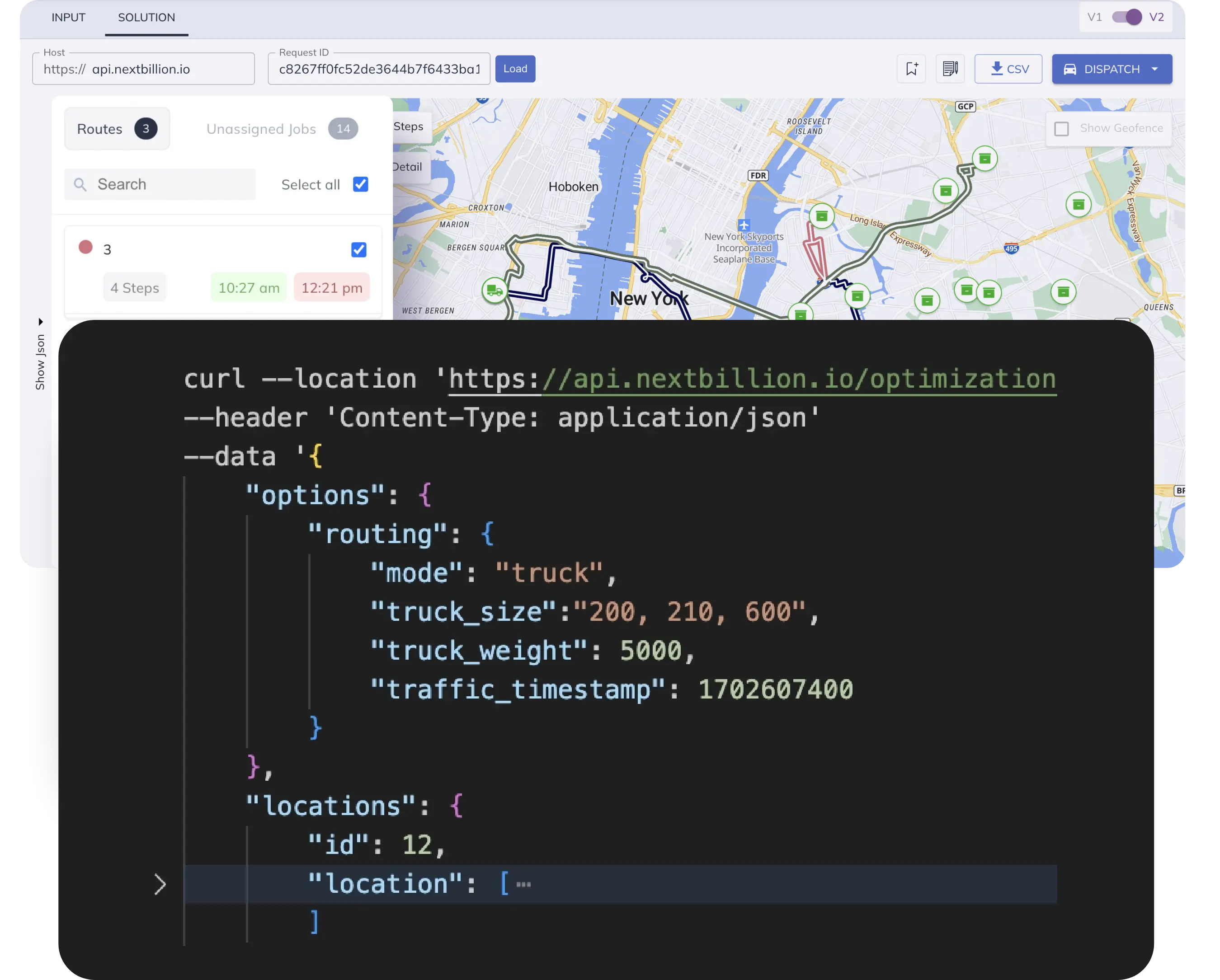

NextBillion.ai’s Middle-Mile Logistics Solution is a powerful tool that can help with many of the above points. Key features include:

- Advanced route optimization with flexibility that allows for last-minute changes to planned routes and 50+ hard and soft routing constraints to enable deep customization of routes to meet unique operational needs.

- Truck routing profiles for routes that are specifically optimized for various truck types. Account for factors like truck weight and dimensions, type and weight of cargo, special permissions and other relevant factors to get quick and easy regulation-compliant truck routes.

- Multi-dimensional capacity planning that optimizes LTL routes, FTL routes, backhaul routes and reverse logistics; considers compatibility between vehicles and goods; optimizes loads for multi-compartment trucks and ensures efficiency and resilience of cold chain logistics.

- Efficient clustering of orders according to selectable parameters like distance, travel time and proximity to each other, which enhances routing, resource allocation and dispatch efficiency.

- Integrations with telematics and transportation management systems that facilitate the plugging in of fleet tracking and routing data from and back into your existing systems like Samsara, Geotab and ServiceNow.

With impactful features like these, NextBillion.ai’s solution empowers retail organizations with better visibility and control over the middle mile, improved truck space utilization and prioritization, the best routes to maximize on-time deliveries and sustainability of operations, reduced transit times and much more.

Such an effectively optimized middle mile confers a strategic advantage over competitors. By investing in advanced logistics technology and processes, retailers can differentiate themselves in the market and attract customers with competitive pricing and superior service. A well-optimized supply chain enables businesses to adapt quickly to changing market conditions, capitalize on opportunities and stay ahead of the curve.

Want to maintain healthy profit margins while offering competitive pricing to customers? You know what you need to do.

Ready to get started?

Request a DemoTable of Contents