Table of Contents

Load optimization can be as typical as a mathematical formula. It is not just about putting the packages inside the cargo but adjusting them efficiently to put in the maximum number of delivery boxes within the available space.

Try filling sugar cubes in a jar. Haphazardly pushing the cubes would leave behind large air spaces. However, by following a unique pattern, you can utilize the jar’s maximum capacity for storing the cubes. That’s load optimization.

The logistic industry’s business model is to receive the delivery boxes and send them to the allocated destination. But with bulk consignments, it is necessary to have a mechanism that ensures optimum utilization of resources.

Load optimization is a necessary integration into the system for analyzing data insights about freight, carriage capacity, or geographical location and creating effective load plans.

The load planning tool considers multiple factors before automatically deciding load placement in the delivery vehicle’s carriage space. The tool prioritizes scheduled delivery packages and ensures their secure placement in the appropriate delivery vehicle.

What are the Challenges Associated with Load Planning?

While loading merchandise on the delivery vehicles, the purpose is always to fit the objects in a way that everything fits comfortably. To manage logistics on a large scale, it is evident to have a mechanism that analyzes space capacity, package volume, weight, delivery routes, and several other factors.

1. Type of Load:

It is foremost to categorize the package into fragile, unbreakable, perishable, durable, tough, brittle, etc. This lets you choose an optimum place of storage for the package to keep it safe and sound.

2. Product in the Package:

The load manager must know the type of product in the package. It can be categorized into electronic equipment, appliances, tools, food (vegetables, fruits, packaged drinks, non-vegetarian items, etc.,) hazardous chemicals, furniture, fabric, and others. It is necessary to choose suitable transportation for specific packages.

3. Consignment’s Volume and Features:

The weight, size, and shape of the delivery box are critical factors for package placement in the transport vehicle. Exceeding the load limit can break down the carrier or can be prone to accidents on the highways.

4. Wagon’s Capacity:

There are different classification of delivery vehicles attached with shipping companies, and depending upon the carriage capacity of each vehicle, the load manager has to arrange the load over it.

5. Weight Placement:

Weight balancing is an important part while putting the packages inside the delivery trucks. Keeping the boxes randomly can make the drive difficult and insecure. Even the vehicle can meet an accident or capsize while turning directionally.

6. Delivery Schedules:

Whether a product is purchased online, or a logistics firm handles bulk delivery for a company, they commit to drop the carriage within a stipulated time. Often on-demand deliveries are raised during transit, which requires order clustering. Hence, during load planning on the trucks, the priorities are to be set on the packages because post-date delivery ruins the company’s reputation.

7. Delivery Route:

A courier company’s hub receives the delivery packs to distribute them into local stations, which are later delivered on multiple routes and destinations. Therefore, it is necessary to consider the delivery routes of the shipment along with factors like size, weight, or category. Even if a delivery truck of a specific route has extra capacity, you cannot load a relevant box that fits into the space but has delivery location on a different route.

8. Delivery Location:

The load manager must possess a brief understanding of the region in which their vehicles operate. It is essential for them to have knowledge about different locations so that they can allocate the load on vehicles that are feasible for reaching wide and open roads, or dense and narrow areas.

You must review all the factors related to the nature and other specifications of the load.

What is the Process of Load Planning And Optimization?

Load planning and optimization is a multi-step process and is entirely dependent on automation technique. Load optimization software integrates with the database and works after synchronizing the parcel data with the system.

Provide Package Details:

As the packages are received at the collection center or during bulk orders from a factory, the item details are instantly loaded on the system. Critical parameters like delviery location with PIN code, weight, volume, and type of product are essentially noted down manually.

Add Vehicles to the Panel:

Logistics companies have multiple delivery vehicles attached. The vehicles are usually categorized on the basis of routes, types of loads, or schedules. Whichever appropriate vehicles are available on the due dates of delivery are added on the panel for taking over the delivery task.

Route Analysis:

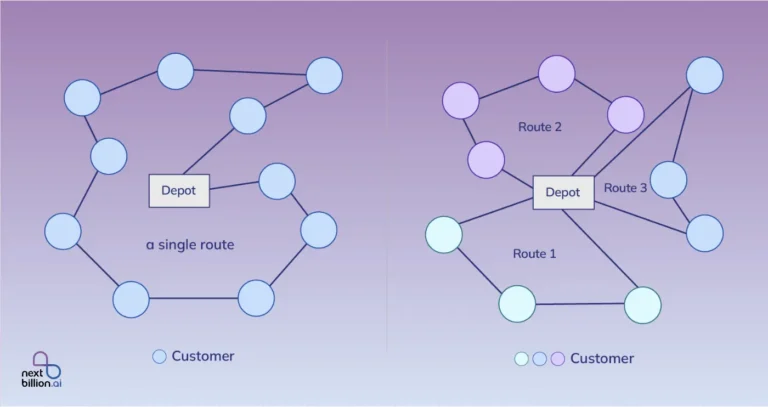

Route analysis and optimization is the key to logistics business. Even in the rare of cases cargo movements between two stations, it is necessary to analyze different possible routes. The integrated tool provides the best directions to the drivers considering the traffic, highways, width of road, etc. It can also alter the routes in real-time due to uncertain scenarios like roadblocks, or sudden pickup calls from a connecting region.

Identifying Loads for Specific Location:

Packages are segregated according to delivery destination in any specific area, which is the first step in load planning. These are also divided based on particular routes in the area, especially for large areas.

Verifying Delivery Schedules:

Often the couriers reach the delivery hub much before the schedule. But the managers have to decide about delivery priorities, if there are other pending deliveries on the route. The software ensures to allocate the delivery boxes to the vehicles while also considering the delivery schedule, along with other parameters. Post-date deliveries provoke customers to make enquiry calls and dilutes the company’s reputation.

Classifying Load:

The carriages are allocated to the available vehicles based on factors such as size, weight, etc. it also considers the number of vehicles on the route. If a wagon carrying a heavy load has enough space to carry small boxes, and can also move swiftly on the designated routes, then the tool will automatically allocate only one vehicle for distribution.

Load Optimization:

Once the vehicle is allocated to a group of packages for delivery, the system shows an automated plan to place the packages in the loading space. It ensures to keep appropriate balance to safeguard the vehicle from toppling. The labors do not get irritated with unnecessary wastage of time and energy due to direction-less settling of parcels.

Live Tracking:

The software enables the managers to track the cargo trucks, and re-route them at any point for instant changes in the plan. It provides accurate transit ETAs and distances between delivery locations. In case the managers get alert about enough space in the truck picking up a package in the connecting route, they can ask the system for re-optimizing the route plans.

Alerts and Reports:

The load optimization software integrates with the ERP and fetches alerts on successful deliveries or any trouble faced on the route. It additionally creates delivery reports for regular analysis and improvisation in load planning.

The algorithm behind load optimization tools is trained on the basis of data insights from multiple sources, and has clarity about the priorities that considers all the individual parameters.

Why Should Logistics Choose Load Optimization?

Load optimization resolves the trouble of the courier companies handling the packages with sophistication. It offers multiple benefits to the organization. Some of them are discussed below.

1. Saves Time and Money:

Effective use of load planning techniques helps in efficient management of deliveries. As a primary benefit for the logistics companies, they can leverage load optimization tools to conveniently set the load inside the vehicle, thereby not wasting time in permutation and combination. The whole process is also cost-effective, as you can finish more tasks in the working hours to reduce labor costs, and right adjustments complete the deliveries in fewer trips. Instant route guidance on the road makes it easy for the drivers to locate the nearest delivery spots from the fastest and accurate direction.

2. Ease of Work:

Load planner tool prominently considers the delivery route while keeping the packages in the sequence of locations entered in the system. The drivers are well-aware about the placements to swiftly drop the parcels without last minute hustle and finish the task on time.

3. Intact Packages:

Load optimization also ensures that all the cartridges stay intact during movement. The packages are placed in a way that even if the carriage vibrates or bumps due to breakers or potholes, it does not shake or tilt. Therefore, it protects the items from getting damaged or spillage on the way to the destination. For example, in a suitable waste recycling business idea, instead of dumping the broken items into the cargo, the load planner tool provides accurate guidelines for keeping the objects in proper order. It helps in maximum usage of cargo space.

There are several other benefits of load optimization, such as sustainable transport, incorporation of the latest trends, customer satisfaction, reduced work load, etc.

Importance of Load Optimization Software for Shipment Companies

There is a significant role of load optimization in the shipping industry. It seamlessly merges into the business processing, and caters to a holistic approach from collection of goods to distribution at multiple hubs and reaching the final destination. Let us understand the importance of utilizing an automated load planning mechanism.

1. Software Integration:

Load optimization conveniently integrates with the company’s database management system. Therefore, there is no need of deploying and managing multiple tools for uploading databases and processing for load management.

2. Vehicle Safety:

Although the primary concern of the logistics company is to satisfy the customers, they cannot avoid the resources used in the transportation. Effective load planning is also suitable for the vehicle’s longevity. Excessive weight, disbalanced freight placement in the trunk, or moving on inappropriate routes can severely affect the mechanical parts like shockers, tyres, or engines, leading to repair and replacement. The load planner tool indirectly addresses these issues.

3. Brand Value:

Courier companies that do not give enough weightage to load planning often face inconvenience and inefficiency during the transition phase of transportation. It affects their commitments towards the customers about timely delivery with zero troubles. Continuous lag in their output can shatter their brand image.

4. Optimum Loading:

The tool assists in sufficiently utilizing the loading space of the vehicles. Haphazard loading eats-up the space to allow lesser number parcels on a trip considering the vehicle’s loading capacity. But optimizing the loads enhances its visible space for loading more parcels in the same trip.

5. Significant Cost Cutting:

Proper load planning creates more space in the delivery trucks, thereby reducing the number of trips. Thus it saves fuel costs, and necessary vehicle maintenance after completing certain travel distances, which is unavoidable due to regulatory compliances.

6. Increased Warehouse Space:

With regular flow of consignments from multiple channels, it is necessary to maintain space availability to keep the carriages safe and secure. Fast and efficient work processing is essential to avoid piling on the pending delivery tasks. The situation may get worse during the festive seasons. Load optimization is a prominent solution to enhance the workflow.

7. Utilizing Work Hours:

Manual load planning consumes more time with idle work hours for the drivers. While the automated system strives for zero human errors by eliminating the involvement of multiple heads involved in the job. It gives proper instructions to the labors for suitably adjusting the loads without needing plan improvization.

8. Customer Satisfaction:

Successful load planning will lead to quick deliveries, and getting the vehicles ready for the next round trip, if possible. It would also clear the delivery schedules of the pending packages, and the efficient processing may also lead to pre-schedule or on-time deliveries. Load optimization also protects the quality of the product and selects secure space for fragile objects.

9. Following Sustainability Trends:

Global organizations are promoting an effective work culture to reduce resource wastage such as fuel, electricity, managing databases, or enquiry mails that recounts carbon footprints. Load optimization quickens the receiving and delivering procedures, reducing the number of trips and thus, emitting less carbon in the atmosphere. Read 5 proven route optimization strategies for sustainable operations.

10. Mid-route Load Allocation:

The load optimization algorithm is designed to manage load plans in real-time and can re-optimize the plan due to slight or major altercations. It can calculate the package details relevant to delivery location, weight, size, or type of packages, and designate suitable space, if possible, mid-way for extra package delivery. Additionally, the software also provides a middle-mile delivery location system to edit the route as per requirements.

Getting Started with Load Planning in Route Optimization

Load optimization in logistics is a complex process, and requires deep analysis of factors that directly or indirectly impact the delivery task. Companies relying over traditional practices like manual planning or higher dependence on labors, fail drastically with higher costs, late deliveries, and over-stressed work culture.

On the contrary, the load planning and optimization system is built for a full-fledged approach in analyzing all the constraints. The tool is quick and efficient in providing instructions on load planning after considering various parameters like vehicle, capacity, route, destination, and load characteristics.

The advanced routing and scheduling technique generates optimal route plans with quick assessment of complicated constraints. You save time and money that was spent unnecessarily on random loading, and build trust among the clients and customers with perfect deliveries.

About Author

Nitesh Malviya

Nitesh Malviya is a research-oriented professional with a background in Computer Science & Engineering. He served for 7 years as a software consultant and wrote passively in the tech niche before becoming a full-time technical writer.