- BLOG

Why Logistic and Shipping Companies Control Tower Needs Custom Routing Intelligence

Published: September 12, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

What happens when your supply chain’s “nerve center” can see everything, but can’t act fast enough to prevent disruption? That is the dilemma many logistics and shipping companies find themselves caught in today. Control Towers deliver visibility, but without routing intelligence they often fall short of delivering true resilience. Visibility alone will not be sufficient in an era where port congestion, weather delays, and rising operational costs are the order of the day.

It’s no surprise then that the global logistics Control Tower market was valued at USD 9.67 billion in 2024 and is projected to more than triple to USD 32.14 billion by 2030, growing at a CAGR of roughly 23%, as enterprises worldwide race to enhance responsiveness and agility. With Control Towers plus custom routing intelligence, businesses can turn reactive monitoring into proactive decision-making. Read on to discover how NextBillion.ai empowers global logistics executives to bridge this gap and future-proof their operations.

A control tower in logistics is a centralized digital platform that offers full visibility, control, and management of the entire supply chain. With a transportation control tower solution, your business can reduce delays and make the most of performance data.

A control tower network oversees key areas like carriers, vendors, freight audits and payments, claims, charge-back notifications, and more. This network is managed by transportation experts skilled in operations, analytics, procurement, and customer service.

The biggest advantage of a transportation control tower is that it combines top-notch transportation technology with experienced professionals who focus on continuous improvement. Unlike a simple software-as-a-service (SaaS) solution that only provides access to technology, the transportation control tower model offers a complete transportation network. You get the technology, expert talent, and a trusted group of carriers to meet your logistics needs.

Early logistics control towers had been created more as a monitoring tool than as a management tool. They gave an imperfect picture of operations but they were not able to dynamically re-rout shipments, predict disruptions, or combine all systems within the supply chain. Therefore, the businesses had to resort to manual interventions, inert data, and dis-joined communication channels, which restricted their potential to create actual efficiencies.

Here are the key ways early control towers operated, highlighting why they fell short of enabling true decision-making intelligence.

Old fashioned control towers were simple monitoring dashboard models. They showed the position of containers, or vessels via EDI (Electronic Data Interchange) messages or carrier reports, but no further. As an example, when a vessel was late in Rotterdam, the system would notify the delay but dispatchers again had to call trucking companies manually, re-book an appointment, or reassign vehicles. This implied that control towers were information devices and not decision making engines.

The systems relied on set inputs of carrier schedules, spreadsheets and manual entries of updates. They did not relate to live feeds such as AIS (Automatic Identification System) vessel tracking, GPS-empowered trucking, live traffic information, and weather notices. Estimated times of arrival (ETAs) were frequently obsolete when problems arose and operators responded to the problems in the cascade instead of responding proactively.

Without predictive analytics, control towers highlighted disruptions only after they had already impacted operations. If border delays forced trucks to miss warehouse slots, the system displayed the issue once it happened. By that point, warehouse teams had to work overtime or leave goods idle. The absence of forward-looking capabilities meant these towers functioned more as retrospective dashboards than proactive control systems.

Traditional control towers assumed a linear logistics flow such as Port A to Truck or Rail B to Warehouse C. They lacked the flexibility to evaluate alternate options like rerouting through a different port, switching to another mode of transport, or leveraging a faster customs crossing. Route adjustments depended on local planners making calls, sending emails, and applying personal judgment. This uniform approach reduced agility and made supply chains less resilient.

Legacy control towers were rarely integrated with Transportation Management Systems (TMS), Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP), or port community systems. The lack of connectivity forced operators to fill the gaps with Excel sheets, phone calls, and email chains. An ocean disruption often did not automatically update inland trucking schedules, creating blind spots and inefficiencies throughout the supply chain.

Since the introduction of logistics control towers in the early 2000s there has been significant development of the same. They were originally thought of as simple monitoring platforms to bridge the distance between high-level planning and ground execution. They were embraced by large shippers who hoped to gain a bigger visibility although such systems soon exposed structural flaws.

Although they worked well in enhancing transparency over traditional, siloed operations, legacy control towers were never intended to be operated in dynamic decision-making, predictive analytics, or an integrated approach with the modern digital ecosystem. Their constraints became clearer with the expansion of global supply chains to be more intricate and prone to disruption.

Here are some of the most prominent limitations of old custom towers:

Old school control towers tended to run on lagging or incomplete data streams. Information flowed on a scheduled carrier update, EDI or manually typed spreadsheet instead of automated and live feeds. In the event of disruptions, e.g. congestion at port, or weather delay, operators were not given prompt insight into the possibility of alternatives. The methods of coordination remained very manual, i.e. the use of emails, phone calls, update meetings which were slow to respond.

Examples include: In the 2021 U.S. West Coast port congestion crisis, vessels spent weeks at anchor, although many control towers were unable to show moving ETAs. There was no system-based means to proactively reassign inland trucking or rail at the hands of planners, which led to major downstream bottlenecks.

The inefficiencies of older systems also made these systems difficult to maintain due to the fact that their inefficiencies were translated into real financial losses. In the absence of real-time intelligence, companies incurred detention costs when containers hung around ports, demurrage costs due to late pickups and increased costs related to overtime as warehouse teams scrambled to process late or rescheduled deliveries.

Unutilized trucks waiting to take instructions were also an additional cost inflator. In addition, older control towers did not usually interoperate with newer and less expensive technologies like cloud-based TMS or AI-based analytics platforms, effectively trapping companies in old and resource-intensive processes that raised the total cost of ownership.

Example: At the time of Suez Canal blockage in 2021, businesses with older systems had little capacity to dynamically compute rerouting paths through the Cape of Good Hope. In a number of cases, there was a huge demurrage and equipment repositioning costs due to decisions based on manual scenario planning instead of automated optimization.

The demand of customers to have accurate, real-time shipment visibility has increased exponentially in recent years, and old control towers were not able to meet this demand. The ETA estimates they made were on the basis of fixed schedules and not dynamic conditions, and therefore the shipments were often shown to be on time by the system, when they were not really on time in reality.

The customers frequently found themselves with problems when shortage of inventory occurred or when they needed to raise issues. This was a failure to proactively communicate which led to a loss of trust, service dissatisfaction and the erosion of brand reliability both with shippers and carriers.

Example: During the COVID-19 pandemic, stores relying on legacy control towers tended to remain unaware of container backlogs until store shelves were filled. In comparison, companies that had predictive, API-based visibility tools could warn customers in advance, change sales forecasts and shift inventory before their reputations were harmed.

One of the worst inefficiencies of the legacy control towers was that they could not scale to large disruptions. These systems were designed to operate steadily and as they could not cope when the norm was not met. Their fixed structures were usually drowned in strikes, natural disasters, port closures, or geopolitical upheavals.

Companies were left powerless to cascading failures in their supply chains without the capacity to quickly re-sequence shipments, prioritize alternative routes, or update plans near-real time. Such events were also slow to recover use of resources and this reduced competitiveness in a global marketplace where agility is a necessity.

Example: During the Russian invasion of Ukraine in 2022, when overland trucking routes into and out of the country were disrupted in Eastern Europe, older types of control towers were not able to recalculate routes as quickly as they did. Shipment became disrupted at the borders, perishable goods became spoiled, and logistics costs soared. Companies that made use of AI-based routing platforms, however, could better adjust and divert flows via Southern Europe with less effect.

Control towers of the past offered visibility but were not very intelligent to help make operational decisions on the fly. The solution to that gap is the modern route optimization that incorporates computational algorithms, predictive models, and system integrations directly into the Control Tower stack. The system does not merely show the position of a vessel or truck but continually considers millions of possible routing options in order to offer the most efficient, cost-effective, and resilient routing.

Here is how modern route optimization equips control towers with computational algorithms, real-time data fusion, and constraint-aware decisioning to actively optimize every leg of the logistics journey.

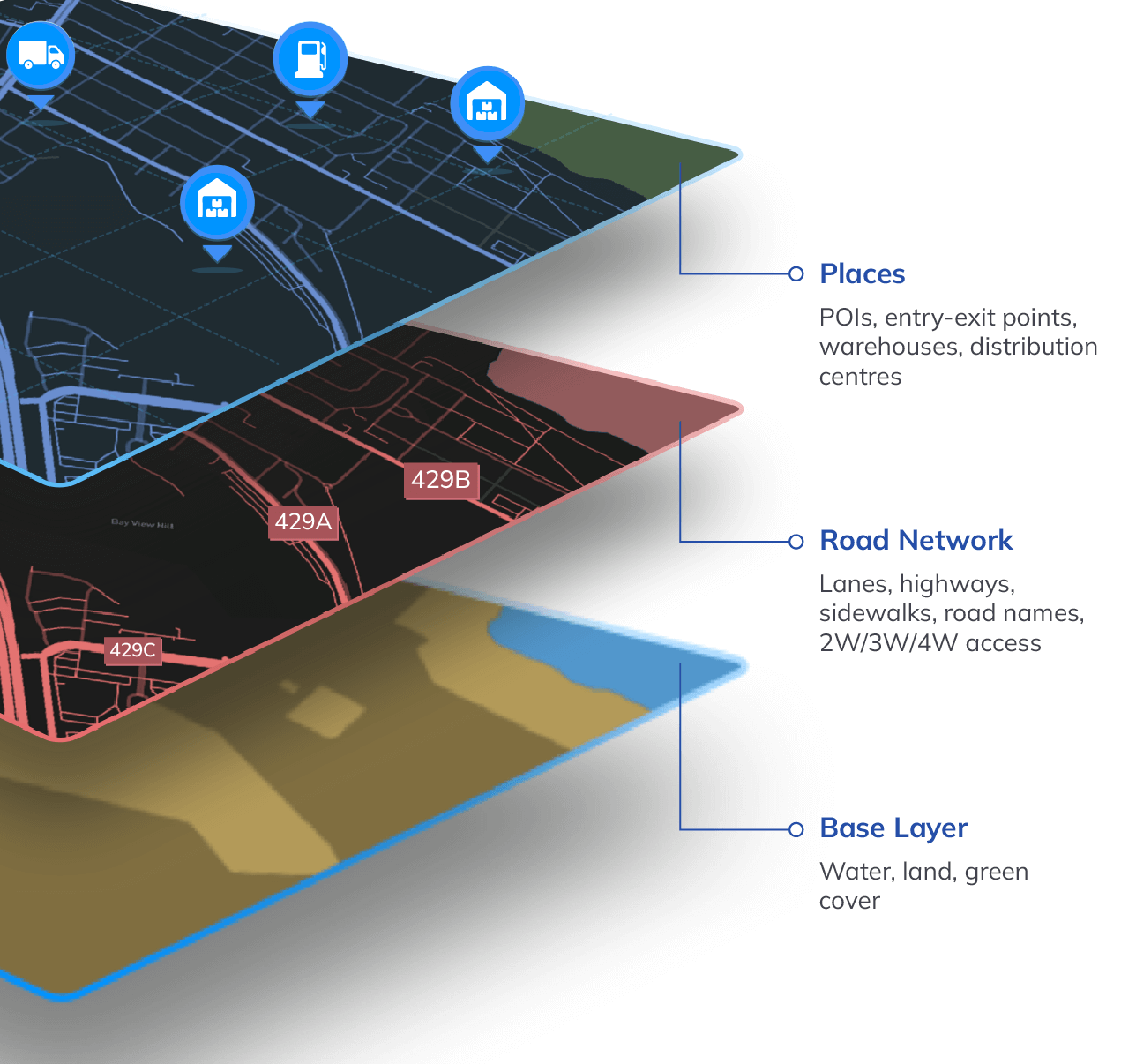

The first step in optimization of the route is structured data acquisition in the logistics network. These are geospatial delivery-point coordinates, hubs and depot locations, time-of-day traffic patterns, areas of congestion in history, vehicle capacity limits, hours of service restrictions on drivers, and delivery time windows. This data is turned into a digital twin of the logistics network in the system that allows simulating and optimizing against real-life constraints.

After construction of the data model, optimum paths are decided through algorithms. Shortest-path problems are solved using a traditional graph theory approach like Dijkstra or A search+. In the case of multi-stop, multi-vehicle complexity, more complex methods can be applied: Traveling Salesman Problem (TSP) solvers, Vehicle Routing Problem (VRP) formulations, or heuristic or metaheuristic methods such as Genetic Algorithms, Simulated Annealing, and Tabu Search. These enable the system to review thousands of routing permutations nearly in real time, trading off speed, distance, cost and compliance needs.

The modern routing intelligence has its strength in the ability to incorporate live data sources right into the Control Tower. Vessels feeds, trucks that have an IoT-capable telematics feed, real-time traffic APIs, weather forecasts, and even regulatory updates are fed into the optimization engine.

To illustrate, when a highway corridor is closed by a sudden snowstorm, the system is dynamic in recalculating the assignments of trucks, warehouse slots, and last-mile delivery paths in seconds to minimize delays and downstream ripple effects.

Routing intelligence is not all about shortest distance. It also involves rules on operation e.g. driver duty, and maximum loading capacity, cold-chain integrity, and schedules of custom clearance, and customer specific service-level agreements (SLAs). Such multi-layered constraints help to make sure that the optimized routes are efficient and at the same time legal as well as operationally feasible.

Modern routing, in contrast to the static plans, is iterative. Optimized routes are fed to GPS navigation and driver applications, and they are constantly checked against live conditions. Re-optimization is automatically activated as disruptions take place. The route data is then fed back into the system as completed and this enhances predictive models in future scenarios. This feedback cycle elevates the accuracy of ETAs, the effects of capacity predictions, and resilience of the entire operations.

Integration, perhaps, is the most transformative part. The routing APIs are compatible with Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP) platforms. This interoperability implies that any route modifications can automatically cause a change in dock scheduling, carrier invoicing, or inventory allocation so that the whole supply chain can remain synchronized.

AI-Powered Route Optimization optimizes the conventional routing model through scaling machine learning and predictive modeling. Such systems constantly compute information across a variety of sources, including GPS telemetry, live traffic feeds, weather patterns, past journey data and geospatial analytics to suggest the most appropriate course of action in evolving circumstances.

Machine learning models trained on historical trip data learns congestion behavior at the time-of-day, seasonal demand peaks, and repetitive bottlenecks. Neural networks are capable of combining different types of data, including traffic congestion, raindrop, and turnaround time at a port, to anticipate disruptions in advance. This predictive capability transforms Control Towers from reactive monitors into proactive decision engines.

Precise optimization becomes computationally infeasible in a situation when the complexity is exponential (e.g. 500 trucks serving 2,000 stops). In this case, heuristics based upon AI like Genetic Algorithms and Simulated Annealing can approximate near-optimal solutions in a relatively short period of time, giving results that trade off speed and accuracy. These methods are scalable in the global logistics systems, in which time-to-decision is of the essence.

Illogical mileage, idle times, and more effective use of assets are decreased through AI-driven optimization. To global shippers, a 5-10 percent boost in route efficiency amounts to millions of dollars in fuel, labor, and fleet upkeep saved on a yearly basis.

AI-based routing decreases operational costs directly by shortening the length of detours, decreasing the time in prison, and avoiding overtime pay. In combination with predictive features, businesses are able to prevent fines like demurrage and enhance profitability without growing the fleet.

Sustainability is now being made a board priority. AI-based routing decreases fuel usage and greenhouse gas emissions by streamlining not only distance, but also speeds profiles, vehicle load balancing, and stop sequencing. This will enable firms to achieve 2012 carbon-reduction goals and increase cost-efficiency.

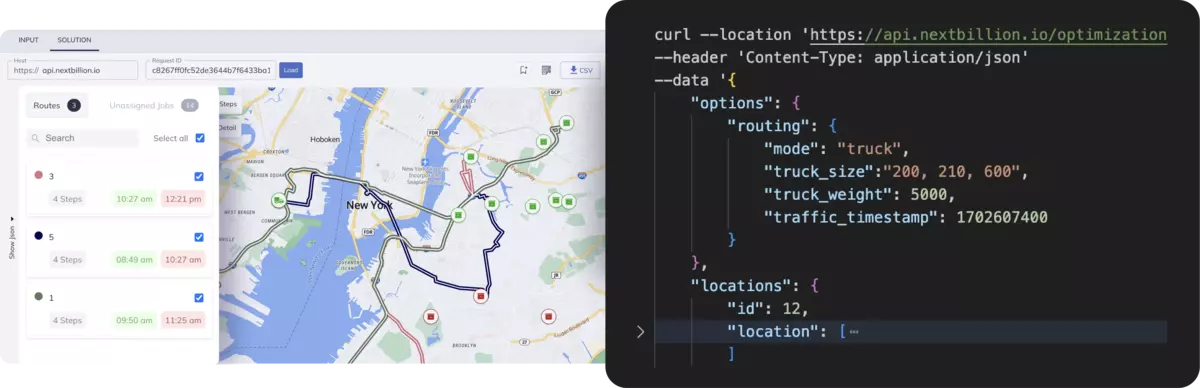

The Route Optimization API of Nextbillion.ai is a robust tool that assists businesses in optimizing their delivery routes to ensure they are efficient and save time and cost. It can solve Single and/or Multi Vehicle Routing Problem (VRP), a traditional optimization problem in operations research, which involves determining the most optimal group of routes.

Use this method to configure the constraints and properties of the optimization problem that you need to solve. Use the fundamental objects – vehicles, jobs, locations and shipments to emulate the scenario that your business needs to optimize. You can choose to use either one of jobs and shipments or use both of them.

Request Parameters:

Use this method to retrieve the optimized solution for the optimization tasks created using the method listed in Build an Optimization Request or Re-optimize An Existing Solution sections above.

Request Parameters:

Use this method to re-optimize an existing solution using the unique ID obtained when the original request was submitted via the Build an Optimization Request method.

Request Parameters:

To constantly manage the changing, real-world logistics operations, control towers need to re-optimize supply chain processes. Consider a Non-Emergency Medical Transportation (NEMT) provider managing daily appointments for 3 vehicles servicing a mix of dialysis, physical therapy, and outpatient visits.

Early in the day, an optimized route plan for 6 patients’ pickup and dropoff is generated and dispatched to drivers. According to the suggested route plan, only 2 vans were used out of the 3 available to complete all the patient drop-offs. However, shortly after dispatching this route, a few changes occur:

Let’s understand how the Re-Optimization feature of Route Optimization API overcomes dynamic changes to the routing constraints. Use the re-optimization method along with the unique ID of the original request to accommodate the new changes – adding 2 urgent patient pickups & dropoff details and removing two shipments which were cancelled – into the existing route plan.

Interpreting the Re-Optimized Route Plan:

Containers can’t leave port until customs is cleared, sequencing rules are exactly what control towers enforce. Relations are used to specify the association between different tasks that should be performed in a certain order. NextBillion.ai’s Route Optimization Flexible API offers three types of relations that the users can enforce:

Jobs & Shipments:

Start by defining 10 jobs and 3 shipments. Let’s define the properties of these tasks:

Vehicles: Next, add 4 vehicles that will be responsible for fulfilling the tasks within the defined constraints. To describe the vehicles and their properties, add:

Locations: Next, define the locations object and add all the locations used in the problem along with a valid id.

Relations: And, lastly, define the relations between the tasks of our choice. For this example:

The Solution:

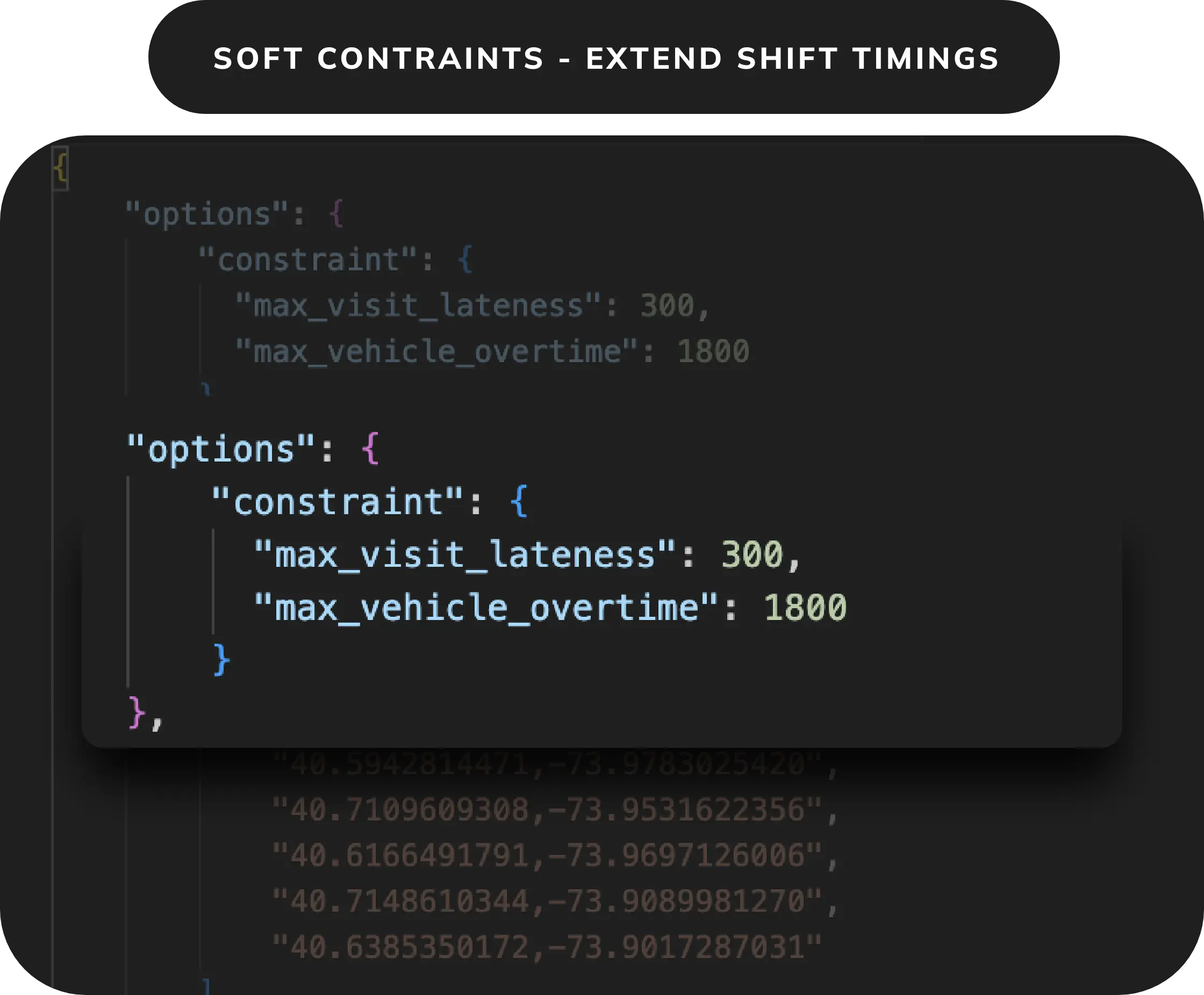

Avoid trucks waiting at borders or depots beyond thresholds to prevent costly detention and idle labor. NextBillion.ai’s Route Optimization Flexible API provides options to control how long the driver must wait after arriving at the task’s location. This feature is helpful when users want to manage the wait times of their drivers or when achieving the lowest wait times is a crucial business goal (for example, consumer-facing services).

Setup: Start by defining 5 jobs and 1 shipment. For these tasks we add:

Vehicles: Next, add 2 vehicles that are going to fulfill the tasks within the defined constraints. To describe the vehicles and their properties, add:

Locations: Next, define the locations object and add all the locations used in the problem along with a valid id.

Options: Lastly, enable the max_activity_waiting_time constraint for the problem. Configure the constraint to keep the waiting time below 8 minutes for each activity.

The Solution:

Control towers need to balance cost, speed, and service level, so APIs that optimize costs while respecting these constraints fit well. The NextBillion.ai Route Optimization API allows you to model real-world business rules. For each vehicle in the plan, you can set any combination of fixed, per hour, per kilometer, and per order costs. Once set, routes with lower costs are generally preferred, while still considering other factors like time windows and task locations.

Setup Example:

Vehicles: Add the 3 vans that are going to fulfill the tasks along with their cost components. Configure each vehicle with:

Cost Types:

The Solution:

A simple control tower allows visibility; however, when it is combined with the custom routing intelligence, efficiency is achieved, and a competitive edge is gained. It makes a logistics operation more proactive and predictive rather than reactive. Control towers can do more than merely tracking shipments by customizing routing algorithms to the particular network, fleet and customer needs of any company to actively optimize each leg of the journey.

With Nextbillion.ai’s Route Optimization API, you have a trustworthy route optimization solution for planning and scheduling your deliveries efficiently and you can experience incredible efficiency savings. Book a demo to get an idea about the numerous possibilities of route intelligence.

A Transport Control Tower (TCT) is an integrated logistics system that can be used for transportation across all modes; road, rail, sea and air. It allows you to continually monitor, analyze and control the movement of goods in real-time through a single consolidated view.

Cost savings from optimizing a logistics network can be significant, as it eliminates waste in transportation, warehousing and inventory management. Optimizing routes and consolidating shipments saves on fuel costs, increases efficiency, and reduces the cost associated with inventory control.

Route optimization offers control towers a unique real-time, intelligent route planning technology that enhances efficiency through reductions in: travel distance; fuel consumption; and vehicle utilization compared to previous routes. This produces measurable bottom-line cost savings in transportation and asset utilization. More importantly, with optimized routes, control towers can take action to mitigate operational disruption, balance transportation capacity among resources, and obtain an academic contribution towards better visibility of the supply chain.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.