- BLOG

Supply Chain Planning in Cross-Border Logistics: Solving the Route vs Cost Tradeoff

Published: September 10, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Table of Contents

What if the cheapest way of transporting goods across the border turns out to be the most costly? In the cross-border logistics world, the safest route is not always the shortest and the safest option is not the cheapest, or with the lowest emissions. Too often, logistics teams are stuck in this sticky web of trade-offs, trying to balance speed, cost, and reliability in the face of congested border crossings, random tolls, and unpredictable customs delays.

This article discusses how improved supply chain planning and the right technology can help businesses address the route vs. cost challenge to enable more efficient, reliable, and sustainable cross-border operations. Let us learn more:

Supply chain planning, when it comes to cross-border logistics, is the strategic process of designing, coordinating and optimizing the flow of goods. This flow is maximized for multiple countries, modes of transportation and regulatory structures. Cross-border logistics planning is thus different from domestic logistics where variables are more predictable and planning must consider customs rules, trade agreements, tariffs, rules for driver compliance, infrastructure quality, and geopolitical risk.

Supply chain planning takes it a step beyond simply mapping out the shortest route on a map, and helps synchronize transport schedules, border delays, cost levels such as fuel and tolls, and service-level agreements (SLAs). Top quality planning incorporates real-time information (traffic, weather, arrival of boats, congestion in the border) and sophisticated optimization tools, scenario modeling, which results in resilient logistics networks.

The bottom line is that cross-border supply chain planning is about making dynamic decisions based on information that will minimize uncertainty. It is a key contributor to on-time deliveries and balances the conflicting objectives of cost efficiency, reliability and sustainability.

When it comes to cross-border logistics, choosing the right route is no piece of pie. All choices have consequences in terms of service reliability, transportation costs, and regulatory requirements. Logistics teams are always trying to find a balance between speed, cost and reliability, while considering the environmental impact of the choices they make. While a low-toll route may make sense on paper, it may be accompanied by annoying border delays.

On the other hand, a fast route might offer the fastest delivery with high rates or with changing fuel prices. And then there’s the most reliable option which could include digitalised customs and fast-track processing, but which could also lead to higher carbon emissions because of the longer travel distances involved. The conflict between outward upside and hidden downside is what makes this such a challenging optimization problem that supply chain planners are wrestling with every day.

Here’s a further breakdown of how these differences tend to play out across the three key drivers:

Factor | Expectation | Reality in Cross-Border Logistics |

Cheapest Route | Lowest total cost, shorter distance → efficiency | Longer border queues, outdated infrastructure, and higher idle fuel consumption lead to delays and hidden costs |

Quickest delivery, minimal transit time | Subject to congestion, unpredictable wait times, or dependency on premium toll roads that erode cost savings | |

Most Reliable Route | Predictable transit, consistent schedules | May involve higher tariffs, longer mileage, or higher CO₂ emissions, undermining sustainability and cost targets |

Let’s dive into a common real-world challenge in cross-border logistics: the trade-off between two different routes from the same starting point to the same destination.

Route A is shorter and only 100 km, it costs $50 in tolls. However, there is a huge downside to it: a border wait of 5 hours, whether because of congestion, inadequate customs capacity, or slow clearance procedures. Route B, on the other hand, is 150 km long and costs $150, but only takes 1 hour at the border because of improved infrastructure, digitized Customs and preferential trade lanes.

The trade-off here is obvious in terms of cost but tactically complex: Route A saves an additional $100 in tolls, but by doing so, adds another 4-hour delay for late delivery windows, overtime expenses, and potentially SLA violations. Route B on the other hand has an extra $100 cost up front, but also involves more reliability, less driver down-time, and more on-time delivery. This situation highlights an important trade-off between cost and resilience that exists in the area of cross-border supply chain planning.

If the direct costs are all that you look at, then you may fail to notice indirect costs such as driver overtime, vehicle wear and tear due to idling, refrigeration fuel used for perishable goods and fines for missed appointments.

On the opposite side of the trade-off, ensuring speed and reliability may drive upfront transport costs, but often protect customer trust, compliance and long-term profitability. In practice, logistics managers will need to dynamically balance these trade-offs based on a number of real-time factors including border wait times, shipment urgency and downstream impacts, rather than just static cost comparisons.

Here are some of the key trade-off factors that logistics teams frequently face:

Border queues can be one of the most unpredictable elements of cross-border logistics. Wait times will vary greatly depending on customs inspection capacity, traffic spikes, seasonal demands (such as export spikes during holidays), and even political events or strikes.

For example, at the Laredo crossing between the US and Mexico, delays can take hours to pass, due to the limited capacity of the bridges; while some crossings in Eastern Europe, such as Poland–Ukraine, can become congested due to security checks and manual inspections. These longer wait times not only result in delays but also increase fuel usage, driver fatigue and risk of violating service level agreements (SLAs).

Trade-off: A shorter, less expensive crossing may mean longer wait times at the border and operational disruptions, while taking a longer or more expensive crossing that includes digitized customs systems or dedicated commercial lanes may reduce variability and improve predictability of delivery.

When it comes to infrastructure investment, different trade corridors are not the same. Take the EU’s TEN-T network for example, or the special toll highways in Mexico, they provide a smoother ride, high-quality infrastructure, and even preferential treatment for commercial vehicles. But there is a catch: these routes are heavily taxed with high toll fees, surcharges for freight, and customs tariffs.

On the other side, lower-priced secondary routes might allow you to avoid those tolls, but they usually come with other obstacles, such as damaged roads, rush-hour congestion and longer travel times. Plus, tariffs can change based on the trade agreement, such as NAFTA/USMCA which has its own specific rules of origin and tax structures to factor into your cost calculations.

Trade-off: You can pay those higher tolls and tariffs to have a more comfortable ride and predictable delivery times. Or, you can save some money by using the lower-priced routes but be willing to pay more down the road for inefficiencies, breakdowns, and missed delivery dates.

Fuel is one of the main contributors to the total logistics cost, particularly in long haul trucking operations. The routes you take can have a big impact on fuel consumption, carbon emissions and your operating costs. For example, if there is a congested area, adding a detour of 50 km might seem like a terrible decision but it might save you 3 hours of waiting time.

That translates into less driver overtime, less refrigeration expenses for perishables and less engine wear and tear from idling. And let’s not forget the variation of fuel prices from country to country, it can be a lot more economical to refuel in one place than another, adding yet another area of complexity to your planning.

Trade-off: You could be spending more on fuel by taking those longer detours for faster clearance, or saving fuel but incurring delays, overtime costs and the risk of penalties or breaches of service level agreements.

When it comes to global logistics, driver HOS rules are vital to ensuring smooth operations. These rules cap the amount of time drivers are allowed to be on the road before they are required to take a break. For example, in the EU, drivers may drive 9 hours a day, or 10 hours a day on 2 days a week.

Meanwhile, the US requires that a truck driver work 11 hours a day, but that is within a 14-hour duty window. However, these limits can be exceeded very quickly when border delays force drivers to make unexpected stops, incur fines, and generally cause constant headaches in your operations.

Trade-off: Choosing a longer, but simpler route can help ensure compliance and minimize scheduling outages. On the other end, a shorter, congested route may save time but can result in non-compliance, increased labor costs, and regulatory penalties.

Customs clearance is one of the biggest bottlenecks in cross-border trade. Customs systems such as the US Customs’ ACE (Automated Commercial Environment) and the EU’s Automated Import System (AIS) make the process of clearing products through customs faster, but in countries where paperwork is still done the old fashioned way, delays can be unpredictable.

If the paperwork is incorrect or incomplete, it can result in cargo being held up, fines, or inspections that delay things further. While more efficient customs processes can involve increased fees or longer diversions, they can result in much lower variability in clearance times.

Trade-off: You can pay a little more now for routes that implement digitized customs and streamlined clearance or stick with paper-heavy systems that are cheaper initially but come with a higher risk of unexpected delays and compliance issues.

Cargo type and urgency are important in defining optimal routes. For example, perishables such as food and pharmaceuticals need fast and reliable transport to prevent spoilage. And, high-value goods such as electronics and luxury items need a predictable journey in order to minimize the risk of theft and insurance problems.

On the other hand, raw materials in bulk shipments can afford to use cheaper slower transportation routes. In addition, temperature-sensitive cargo can incur greater refrigeration charges if trucks have to wait at borders, and dangerous goods have to comply with ADR (European Agreement concerning International Carriage of Dangerous Goods by Road) regulations that can severely restrict route options.

Trade-off: Pick more expensive and faster shipping routes for time-sensitive or high-value cargo compared to cheaper and slower shipping options for bulk or less time-critical cargo.

Cross-border logistics are affected by different geopolitical factors such as political unrest, strikes and regional conflicts. Take the Russia-Ukraine conflict as an example, which forced the redirection of key freight corridors across the Eastern European theater. In addition, strikes at French borders can delay shipments within the EU. While high-risk routes may save some money, they also put carriers at the mercy of cargo theft, increased insurance rates and the need to divert mid-journey.

Trade-off: Choose either less expensive but riskier crossings which come with security issues or invest in safer and more politically stable routes which may involve higher tolls, insurance and longer distances.

As corporate commitments to ESG (Environmental, Social and Governance) targets increase, carbon emissions are increasingly important. For example, longer detours are associated with higher levels of emissions, whereas quicker border crossings may contribute to lowering idling and the overall carbon footprint. Some shippers are now making a deliberate effort to prioritize low-carbon routes even if they are not cost or speed competitive.

Trade-off: Optimize routes around carbon reduction at the expense of paying more in tolls and tariffs, or optimize cost or speed at the expense of corporate sustainability agendas.

Cross-border logistics is not a fixed planning problem that can be solved with a single best practice. Instead, it’s data-driven, dynamic, technologically-enabled decision making that takes into account ever-changing operational conditions, shipment demands and sustainability aspirations.

Here are the best ways for dealing with this challenge:

Border congestion, traffic congestion, weather and vessel arrival times (ETAs) are not predictable and can vary on a minute-to-minute basis. Traditional static schedules don’t work because they are based on historical averages.

By bringing live data feeds (such as real-time border wait time APIs, AIS (Automatic Identification System) vessel data, and customs clearance updates) into a logistics control tower, planners can make routing decisions based on current conditions and not yesterday’s projections. This streamlined plan of supply chain planning cuts down the amount of exposure to unforeseen delays and cost overruns by an order of magnitude.

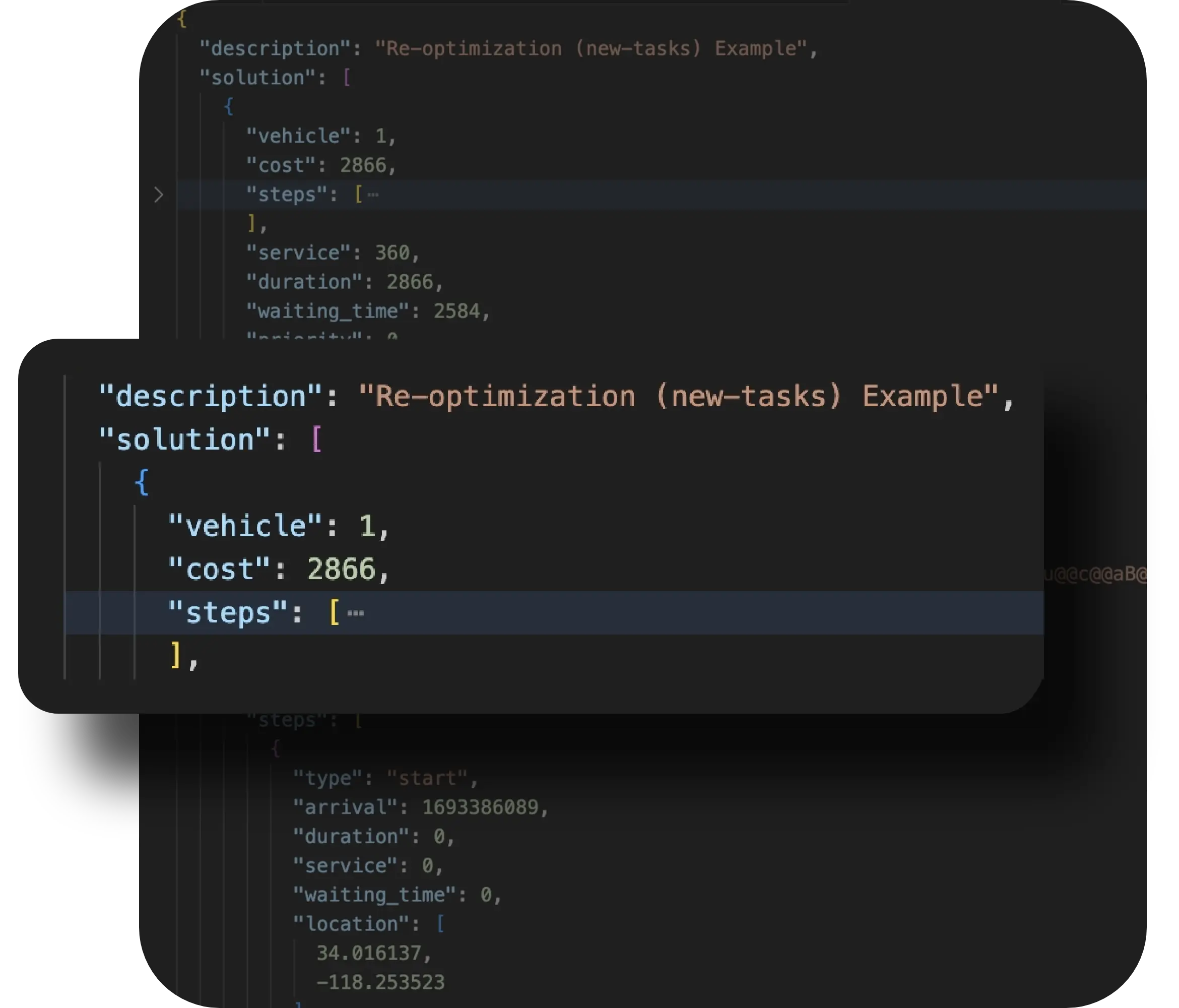

Once a route has been chosen, delays or disruptions can cause carriers to cling to less than optimal routes. A route optimisation API can resolve this, by dynamically recalculating the best available solution. If delays at border crossings reach thresholds or road conditions take turns for the worse, the system automatically diverts trucks to other crossings, changes multimodal connections, or re-tymes deliveries. This allows the logistics networks to be dynamic rather than fixed within a plan.

Often, the cost vs. time trade-off is only noticed when the damage is done by management. Scenario modeling is a way to proactively make decisions by simulating what-if scenarios. For example: What is the incremental cost of rerouting via Pharr if the Laredo crossing delay is greater than 3 hours?

With modeling tools built into control towers, planners can stress-test routes against a variety of scenarios (congestion at borders, weather, strikes), allowing them to respond proactively instead of reactive firefighting.

Not all of your shipments are equally critical or sensitive, but most logistics networks treat them the same. A tiered routing approach, that is in alignment with your customer SLAs and cargo requirements:

This is the optimum strategy for allocating resources, minimizing penalties and the probability of customer dissatisfaction.

Evaluation of routes is typically subjective unless you have a standardized approach. A Cost-Time Reliability Index (CTRI) is a scoring model that gives various dimensions equal importance:

By objectively quantifying the routes, CTRI removes the guesswork. It gives planners the immense confidence that they are selecting the solution that is best for business priorities.

If a control tower determines that a favorable route exists, implementation can break down if plans are not transferred smoothly to operations. By connecting routing APIs directly to the TMS, route changes automatically adjust dispatch instructions, driver schedules and customer ETA notifications. It completes the loop from decision to execution and gives visibility in real time with fewer manual touch-points.

With a growing emphasis on corporate ESG commitments, route optimization needs to go beyond time and cost. By factoring in carbon emissions into the decision-making process, companies can balance financial efficiency with sustainability goals. This means shippers can provide customers with routing choices such as fastest, cheapest or greenest, to both bolster brand reputation and ensure regulatory compliance in environmentally-regulated markets.

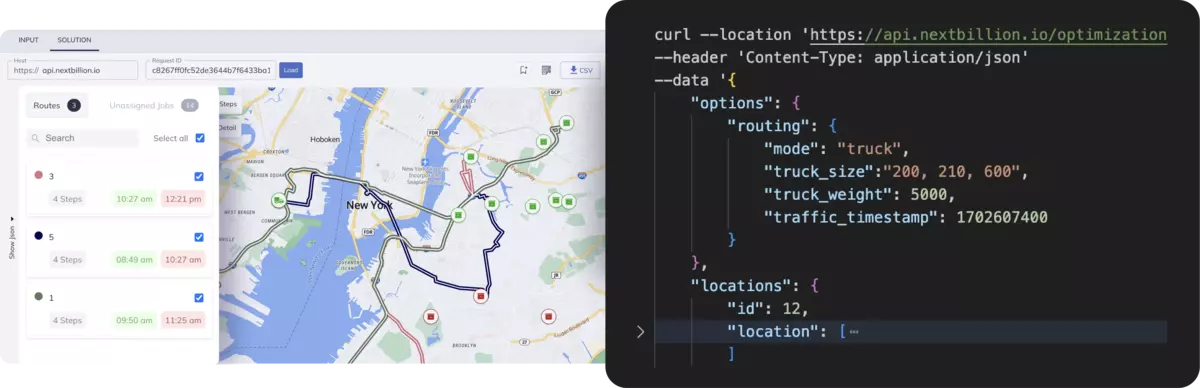

A Route Optimization API is the technological backbone enabling all the above capabilities. It ingests real-time data, applies optimization algorithms, and continuously recalculates optimal routes based on shifting variables.

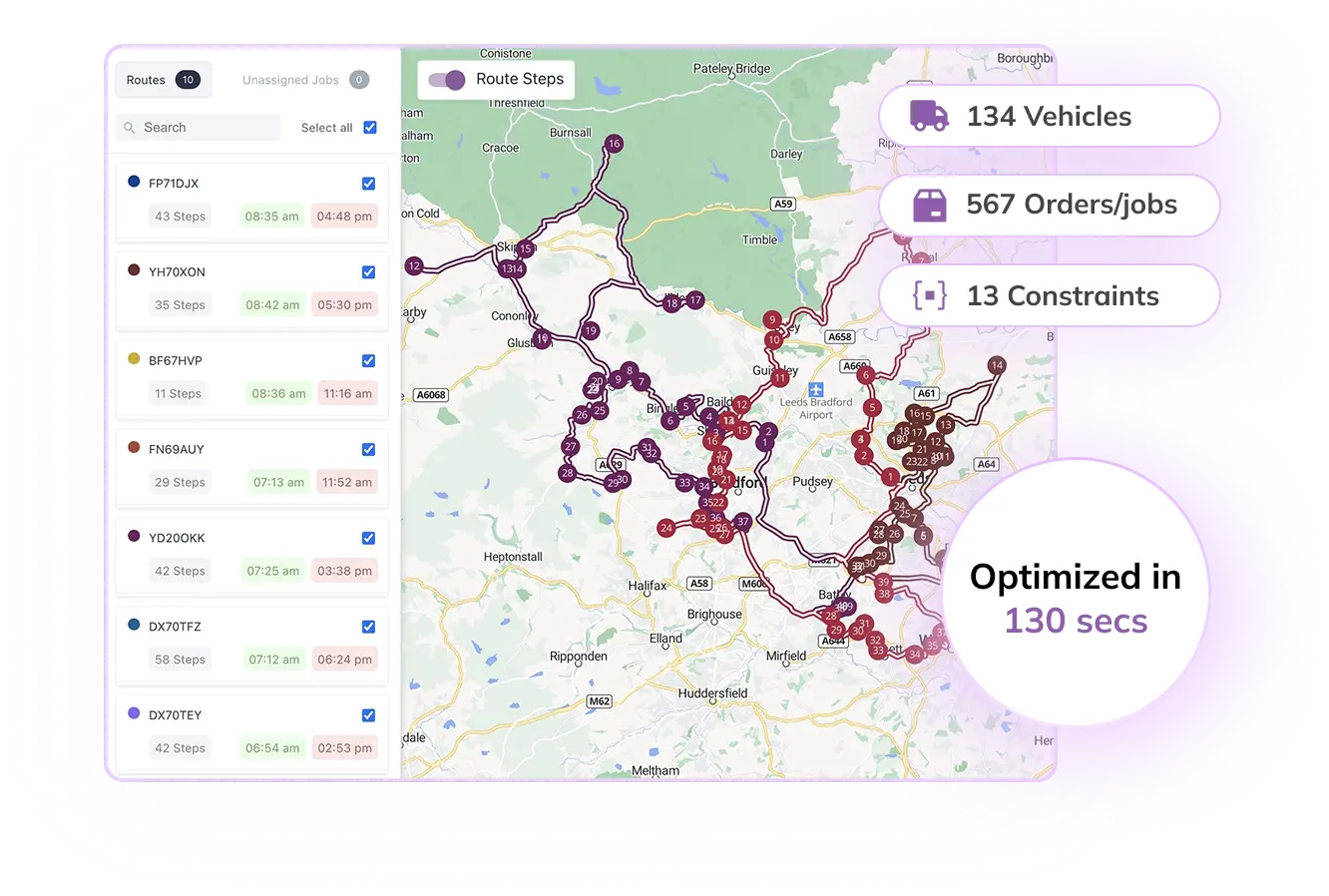

NextBillion.ai is a highly configurable route optimization engine for complex logistics networks:

Solutions such as OptimoRoute are well suited for the traditional fleet optimization, NextBillion.ai stands out in the context of cross-border logistics and the large-scale logistics environment characterized by multi-constraint optimization and real-time dynamic rerouting. With its extensive configurability, API-first approach, and integration capabilities, it is more suitable for enterprises experiencing complex international freight movements.

Trade-off Factor | Challenge in Cross-Border Logistics | How NextBillion.ai’s Route Optimization API Helps |

Real-Time Data Integration | Border wait times, traffic, and weather conditions are unpredictable, leading to outdated schedules. | Ingests live data streams (traffic, border congestion, AIS vessel data, customs updates) into routing decisions for up-to-the-minute accuracy. |

Dynamic Routing & Re-Optimization | Once a route is chosen, delays lock fleets into inefficient paths. | Continuously recalculates optimal routes; reroutes trucks automatically when conditions (delays, traffic, closures) exceed thresholds. |

Scenario Modeling (“What-If”) | Managers cannot anticipate cost/time impacts until too late. | Runs simulations (e.g., if border delay > X hours) to evaluate alternative routes in advance, enabling proactive planning. |

Cargo Prioritization | Urgent shipments (perishables, high-value) are treated the same as bulk goods. | Classifies shipments by urgency/type and applies differentiated routing logic aligned with SLAs. |

Cost-Time Reliability Index | No standardized way to compare route options objectively. | Uses multi-constraint scoring models (time, cost, delay variance) to rank and recommend optimal routes. |

TMS Integration | Optimal plans identified but execution remains manual and siloed. | API integrates with Transportation Management Systems (TMS), automatically updating dispatch, driver schedules, and ETAs. |

Sustainability-Aware Routing | Routes optimized only for cost or speed, ignoring ESG targets. | Adds carbon footprint into route calculations, enabling fastest, cheapest, or greenest options for customers. |

In cross border logistics, routing intelligence makes the supply chain planning process a proactive, data-driven discipline, moving away from reactive troubleshooting. By leveraging the power of advanced algorithms, real-time data feeds, and integration with Transportation Management Systems (TMS), businesses can unlock real operational and financial benefits that would otherwise be unattainable.

Fuel, toll, and idle time are some of the biggest cost line items in international freight. Routing intelligence reduces unnecessary detours, eliminates inefficient crossings and minimizes idling at congested borders. By dynamically recalculating routes, fleets can burn less fuel, wear-and-tear on assets is minimized and toll spend can be optimized between premium and secondary corridors. The result is tremendous savings for per kilometer and per shipment.

Delivery schedules can often be disrupted by traffic, unpredictable customs clearance times, and border congestion. With dynamic routing, fleets avoid bottlenecks on the fly. This reduces the number of missed Service-Level Agreements (SLAs), secures customer confidence and avoids contract penalties. For industries such as automotive or pharmaceuticals, which have largely adopted just-in-time supply chains, this reliability is mission-critical.

Waiting trucks, delayed plant operators, and waiting containers have a direct effect on fleet productivity. Optimized routing ensures that trucks are always in operation by maximizing the number of miles that are truly driven while maintaining driver hours and ensuring that drivers are not idling. Plus, higher scheduling accuracy for warehouses, loading docks and distribution centers, allowing upstream and downstream to flow more easily.

The fast vs. cheap trade-off tends to squeeze margins when companies rely too much either on speed or on savings. Routing intelligence provides a data-driven compromise between these two metrics. This eliminates unnecessary premium spend on every delivery and reduces the hidden costs of delays, over-time or SLA breaches. This results in more consistent and predictable profit margins over time.

Better ETAs, consistent performance in delivering the product, and less fighting over delays means increased customer satisfaction. For retailers and e-commerce players, this translates to enhanced brand reputation, fewer complaints, and improved customer retention. Dependable routing creates long-term trust and repeat contracts in B2B supply chains.

Cross-border logistics are subject to complex regulations, such as Hours-of-Service (HOS) rules, hazardous materials restrictions, and customs clearance procedures. Routing intelligence empowered by supply chain planning allows you to ensure that plans comply with these requirements while automatically taking into account driver rest time, cargo restrictions and restricted corridors. This ultimately becomes a smart way to reduce the risk of fines, legal exposure and damage to the organization’s reputation, as a result of non-compliance.

Cross-border logistics will always be a trade-off between cost, speed and reliability. But with the latest in routing intelligence, supply chain planning no longer needs to be a gamble. By combining real-time data, dynamic re-optimization, and sustainability-conscious planning, companies can transition their supply chain from a reactive problem-solver to a proactive strategic decision maker. The result is reduced operating costs, reduced delays, increased compliance and happier customers.

With NextBillion.ai’s Route Optimization API, you can integrate real-time data, dynamic re-optimization, and sustainability-aware routing at scale into your operations. Contact us to learn how NextBillion.ai can help you resolve the route vs. cost puzzle and create a faster, more reliable and more profitable supply chain.

Routing intelligence platforms allow live data feeds (traffic, border delays, customs updates) to be integrated into one control tower view. These smart and organized platforms allows planners to have total visibility of fleet performance across multiple borders and corridors.

Yes. From reducing idling to minimizing detours and incorporating emissions into optimization models, routing intelligence not only looks after the bottom line of cost and time but also supports sustainability goals.

Absolutely. APIs such as NextBillion.ai are built to scale across different geographies. They allow companies to operate complex multi-country logistics networks with different regulations, cargo types, and route restrictions.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.