- BLOG

Cold-Chain Compliance Checklist for Fleet Managers

Published: November 14, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Table of Contents

What happens when a single degree becomes the difference between life-saving medicine and a million-dollar loss? Cold chain integrity is widely recognized as a crucial line of defense against massive financial damage, regulatory penalties, and even life-threatening consequences. With stakes this high, what is the most important step a fleet manager must take?

For today’s fleet managers, compliance is a necessity driven by the surging demand for temperature-sensitive goods like pharmaceuticals and fresh foods. Even minor deviations from required temperature ranges can result in spoilage, product recalls, and irreversible value loss. That’s why implementing a cold-chain compliance checklist is essential, it builds the operational backbone needed to protect high-risk cargo.

But the reality is clear: traditional manual processes can’t keep up. The real game-changer is AI-powered fleet management software, capable of adapting routes in real time based on temperature fluctuations, traffic, and weather conditions. By choosing the fastest and most temperature-stable paths, it turns compliance from a challenge into a guarantee.

Let’s dive into the essential cold-chain compliance checklist every fleet manager should have.

Do you know?

In 2024, the world cold chain equipment market had a valuation of $292.1 billion, which suggests that a lot of investment will be required to ensure that products are kept safe.

Cold chain compliance means complying with stringent industry regulations concerning the transport, storage, and handling of temperature-sensitive products. All regulations are designed to make sure that products remain safe, effective, and usable or consumable. It includes:

For fleets, regulatory compliance should not only consider the fact that the reefer must keep something cold, even though maintaining proper temperature is important, they also want documentation of temperature integrity.

Regulators, shippers, and customers want proof that the products stayed in the proper temperature range from origin to final destination.

HACCP (Hazard Analysis and Critical Control Points) | Focuses on identifying and managing risks in food safety during transit. |

ISO Standards (e.g., ISO 22000) | Specifies requirements for food safety management systems, including transport processes. |

WHO Guidelines for Pharmaceuticals | Ensures the safe transportation of medicines, vaccines, and biologics under specific temperature conditions. |

FDA and Local Regulations | Mandates specific requirements for cold chain logistics within the food and healthcare industries. |

Cold chain compliance has ceased to be a refrigeration issue, but now it is a key pillar of global health resiliency, supply chain credibility, and economic stability. Cold chain in 2025 is where there is a convergence of biotechnology, climate volatility, digital regulation, and consumer trust. A temperature variation ceases to be a logistical mistake, it is an indicator of system malfunction.

Below is a deeper look at the forces reshaping cold chain compliance in 2025:

The cold chain of the modern world is not only preserving products, but it is preserving the biochemical structure of what is being shipped.

By 2025, cold chain integrity will no longer be the issue of maintaining things cold, but rather maintaining the molecular identity, therapeutic effect, and food safety at the biological level. Temperature has ceased to be a condition, but a pharmaceutical input and determinant of food safety.

The regulators are no longer conducting post-incident audits but ongoing digital enforcement. Governments are shifting to sensor-verified compliance, where instead of requesting fleets to demonstrate compliance, they request them to demonstrate sensor-verified compliance, where:

In 2025, the RegTech in logistics will emerge, i.e. the laws that are enforced through data, not paperwork. Fleet managers are no longer evaluated on what they report, but what their systems record automatically.

Cold chain destruction is no longer perceived as an isolated loss, but it is now known as a destabilizer of a supply chain.

Cold chain compliance is the barrier against sunk costs, insurance claims, carbon penalties, and reputational write-offs in terms of finances.

In 2025, waste is now considered by corporate ESG metrics and a carbon taxation as a climate cost, and no longer a logistics failure. Cold chain non-conformance is turning into an emissions and sustainability liability.

Shippers no longer purchase transport in 2025, but data assurance.

The new value hierarchy:

Old Freight Value | New Cold Chain Value |

“On time” delivery | “On time and in-temp” delivery |

Proof of delivery | Evidence of integrity of temperature |

Carrier reliability | Transparency of temperature based on data |

Cost per mile | Risk per mile |

The selection of fleets is changing to credibility-based. The currency of trust is not promises, but live thermal monitoring, unalterable records, and predicted risk scores via AI. Adherence is no longer a defense, it is a selling point and branding distinction.

Inventory is aggressively affected by cold chain malfunction. It has an impact on disease control, infant nutrition, chronic care, and national emergency reserves today.

The cold chain has become the same as sterile water or clean electricity, which is a vital utility to the population. Shipping is not a problem of failure. It is a communicable disease outbreak.

The first decade to be actively destabilized by global warming is the 2025, where temperature-sensitive logistics is destabilized:

The compliance of cold chains has ceased to be simply technical, now it is associated with climate adaptation, energy strategy, and ESG scoring.

In cases where humans are tracking temperature, non-compliance is responsive. Non-compliance can be predicted when AI controls the temperature.

The AI-based cold chain systems now have the ability to:

Compliance is shifting towards rules to algorithms.

Key Performance Indicators (KPIs) represent important metrics that enable fleet managers to maintain efficiency, safety and dependability within the cold chain ecosystem.

This checklist is for fleet managers guiding them through the main steps required to attain regulatory compliances and to prevent temperature excursions for commodities classified as perishable and high value, temperature-sensitive cargoes.

Most critical failures willingly happen before the truck leaves the yard. This phase thus ensures that all refrigeration equipment and monitoring systems are validated and calibrated to be ready for the specific load.

Checkpoint | Action taken |

Reefer Unit Function | Verify that the refrigeration unit (reefer) powers on, holds power, and operates as designed regarding temperature set-point adjustment. |

Pre-Cooling Verification | The reefer unit has been pre-cooled and has been verified to be at or below target temperature prior to loading. |

Sensor Placement | Confirm that all real-time IoT temperature sensors are positioned appropriately in the cargo compartment to monitor temperature in the warmest and coldest area. |

Calibration Records | Verify that the temperature monitoring sensors/probes have current calibration certificates (typically you renew these annually). |

Temperature Mapping | Confirm that the truck/trailer has recently undergone temperature mapping (validation) to provide evidence of adequate temperature distribution in the cargo compartment. |

Backup Power/Fuel | Check the auxiliary fuel levels for the reefer unit, and ensure the backup battery for telematics/monitoring systems is operational. |

Air Chutes/Seals | Examine air chutes for obstructed airflow and damage and check that all rear and side door seals are intact for proper insulation and tight closing. |

This covers the entire loading process and continuous monitoring protocols that would sustain the cold chain while the vehicle is in motion.

Checkpoint | Action taken |

Proper Loading | Be sure that the cargo is loaded to maintain proper airflow around the walls, floor and ceiling (at least 2 inches), and the air chutes are not blocked. |

Set-Point Locked | Verify that the temperature set-point is appropriately programmed, has been reviewed with dispatcher and driver, and is generally locked to avoid accidental change. |

Real-Time Monitoring | Check if the telematics system is actively sending temperature data to the central dashboard and that geo-fenced alert thresholds are in place. |

Minimizing Door Openings | Driver should reduce the amount of door openings (particularly at multi-stop routes) and uses staging areas effectively. |

Temperature Excursion Protocol | The driver is aware of the particular protocol (i.e., instant alerting, safe pull-off, and basic troubleshooting steps) if a temperature deviation alert indeed is received. |

Contingency Plan Check | The Fleet Manager has immediate access to a list of authorized emergency service providers for reefer repair along the planned route. |

Chain of Custody (Pharma/High-Value) | Confirm the digital or physical sign-off at pick-up with the date and time, temperature, and condition of the cargo. |

Compliance is ultimately proved by accurate and permanent records. Data retention and process refinement come in this phase.

Checkpoint | Action taken |

Digital Record Archival | The data sets on digital temperature logs (time, place, and temperature) automatically generated are archived and kept for the stipulated period (e.g., FSMA requires one year). |

Audit Trail Verification | Confirm documented corrective action reports (CAPAs) for any temperature alerts or deviations attached to shipment records. |

Incident Review | Make sure each temperature excursion, even the minor ones, must have a mandatory root cause analysis. |

Driver Training Records | Verify that all drivers handling cold chain cargo have current training records covering FSMA, GDP, and company SOPs. |

SOP Review | Annually, review Standard Operating Procedures (SOPs) and update them as necessary, with lessons added from review incidents. |

Vendor/Carrier Compliance | Keep copies of all records of compliance with cold chain regulations (calibration, insurance) for all freight carriers, and ensure they measure up to your internal standards. |

Maintenance History | All preventative and corrective maintenance records for reefer units and sensors need to be logged and will define easy access for a regulatory audit. |

The logistics and transportation industry, and especially cold-chain logistics, has never found it harder to keep a fleet in compliance. The strict Hours of Service (HOS) and Electronic Logging Device (ELD) regulations are forcing the fleet operators to maintain proper records, ensure that the drivers are in compliance, and be prepared to conduct an audit all the time. Nonetheless, many individuals still persist in using old-fashioned or manual methods that are labor-intensive, prone to errors and difficult to scale.

The use of AI-based compliance solutions by modern fleets is keeping them ahead of the pack. These systems can give real-time information that can be used to prevent issues even before they occur by automating the most essential processes such as break in logs audits, detection of violations, and monitoring driver performance.

Businesses such as NextBillion.ai are paving the way, with smart compliance solutions that easily integrate workflow with current systems while increasing operational efficiency, and simplifying compliance management at scale.

Some of the top benefits of fleet management solution includes:

Nextbillion.ai provides a complete set of tools that address the challenges of cold chain truck routing and navigation, including route optimization, compliance, real-time tracking and post-trip analysis. These tools strive to increase efficiency, promote compliance and reduce operational risks, all of which are vital for the modern trucking business.

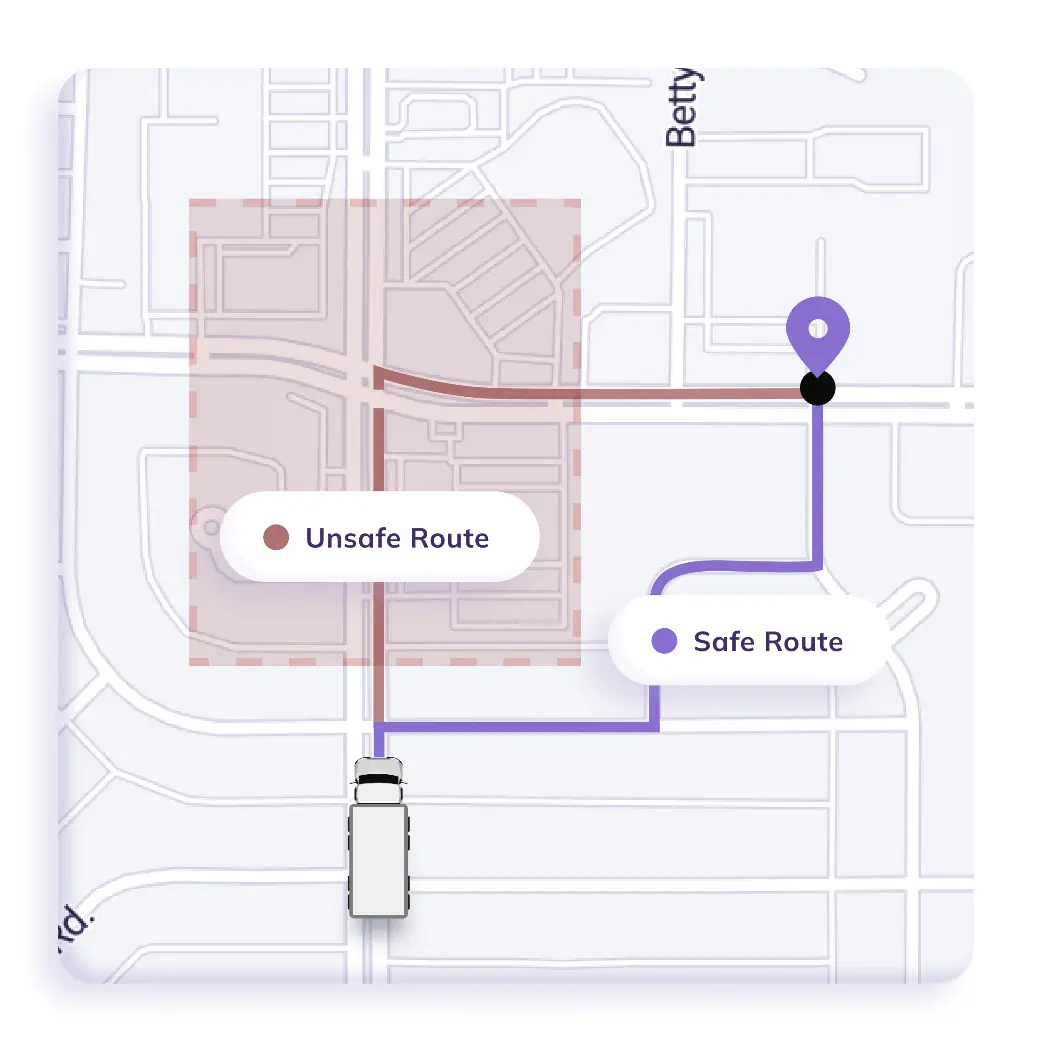

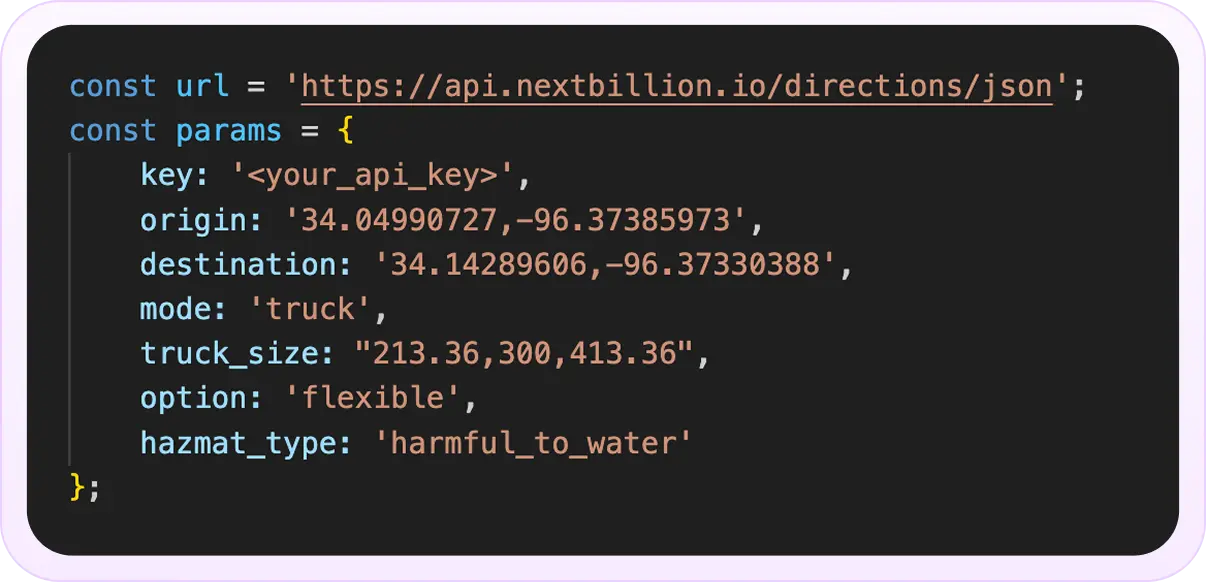

The routing APIs available from NextBillion.ai can also consider what type of material is being put on your trucks. You can use the “hazmat_type” parameter to specify what type of hazardous material is being transported. The routing engine will then only return suggested routes appropriate for the specified truck type. This allows for a level of safety and legal compliance, in that the truck will take only safe routes as per the specified parameters.

Let’s take a look at the request below, which makes use of:

Route Optimization API by NextBillion.ai allows significant customization with more than 50 parameters that simulate real world route planning constraints. One helpful configuration parameter, drive_time_layover_config, allows users to comply with truck driver Hours of Service laws (which require designated breaks). After mapping the driving time laying configurations, the optimization service responds with:

(All in tune with the stated outcome)

Users can create a Route Optimization request by establishing, in order, locations, tasks, vehicles, and Hours of Service mappings.

The Isochrone API of NextBillion.ai allows you to specify which areas are reachable by your trucks under a specified set of constraints. The Isochrone API will consider the average traffic as per the specified departure_time and give you a bounded region that your truck can cover under a specified travel time or distance.

This information is useful for making acceptance or rejection criteria decisions based on business-related issues. For example, you can use the Isochrone to accept or reject orders that can not be serviced in a certain time, or decide the best places for a dark store to maximize order fulfillment.

The following request is offered as an example:

NextBillion.ai’s routing APIs includes a powerful “avoid” parameter to customize routes in line with different business needs of fleet operations. Users can take advantage of the various avoid options, simply to avoid routing on paying tolls, service roads, highways, or potentially dangerous u-turns or sharp_turns. These options give a high degree of flexibility to serve routes constraints of different vehicles while also meeting business needs.

In this, we will request a directions using the Directions API with

Here we shall make a request to the Navigation API to create a route that can be used by a freight truck, avoiding sharp turns and u-turns. We specify:

NextBillion.ai’s Distance Matrix API utilizes present and past traffic conditions to produce accurate ETAs as well as create optimal paths. The Distance Matrix can support one to many and many to many scenarios based on a defined set of origin locations and destination locations. Users can also customize the request using a range of other configuration options that are included in the service.

Below is a request for realtime ETAs for a fleet of pickup trucks getting to and from a defined set of locations.

Cold chain fleet management covers the practices needed by industries that rely on perishable goods. Knowing why compliance matters and using the right tools can make a big difference to operations and trustworthiness. By adopting key features and following best practices, companies can protect quality and safety, which helps consumers and boosts their reputation. Handling cold chain logistics can be tough, but a fleet management software like Nextbillion AI for transport and logistics can make it much easier.

Book a demo and streamline cold chain logistics operations today!

Cold chain logistics involves the transportation and storage of temperature-sensitive goods in controlled conditions, to help ensure quality, safety and security throughout the supply chain. Cold chain logistics is essential for perishable items such as food, pharmaceuticals, and chemicals.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The two main types of cold chain are:

The four Rs of cold chain logistics include the following:

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.