- BLOG

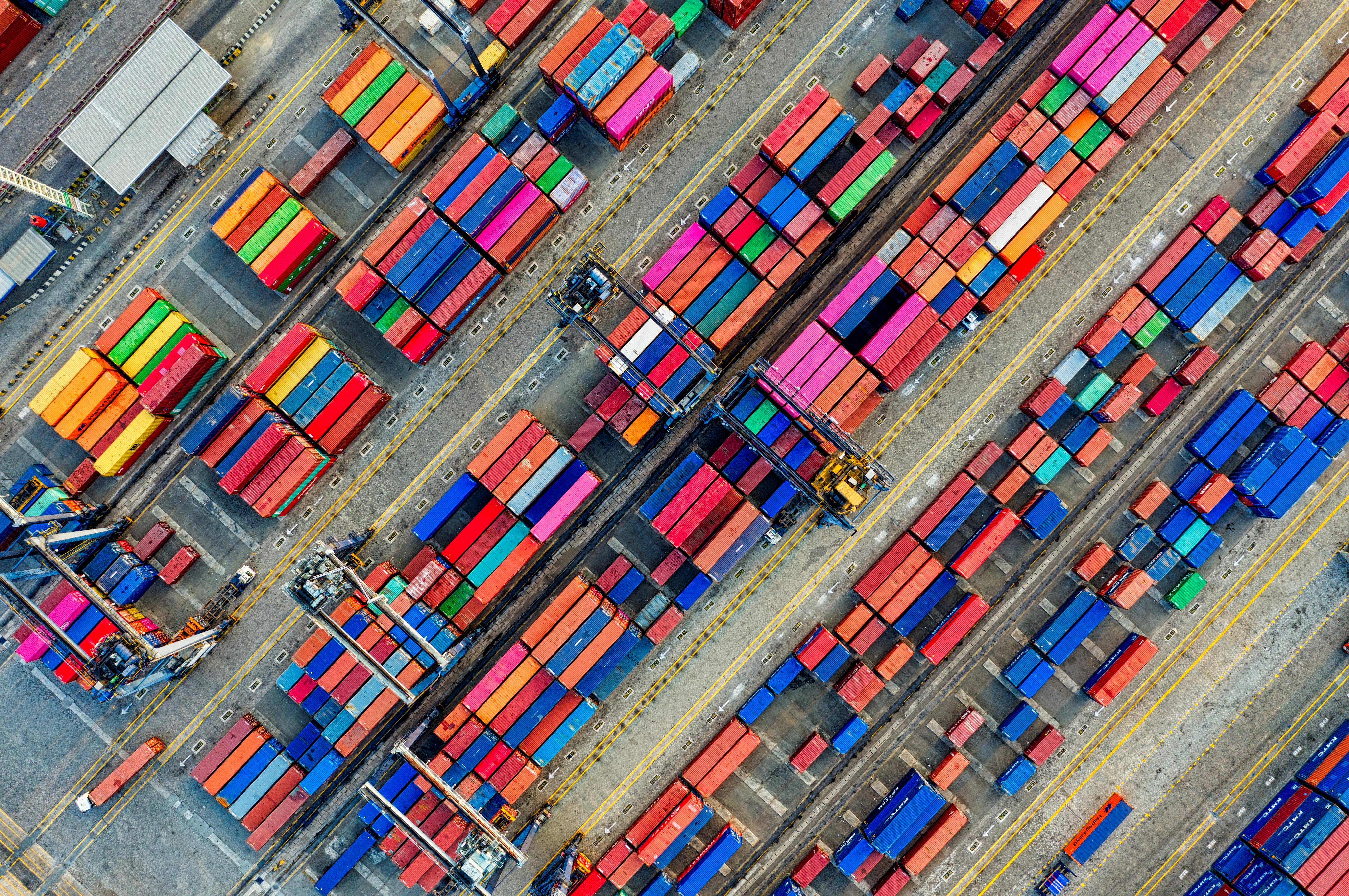

Inside Maritime Supply Chains: Unifying Inland and Port Routing with APIs

Published: October 31, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Table of Contents

What if the world’s busiest ports could talk to inland trucks and trains in real-time: scheduling pickups, avoiding congestion, and cutting delays before they even happen? That’s exactly the promise of maritime supply chains powered by APIs.

From global shipping lanes to inland logistics hubs, the journey of cargo is a complex web of routes, handoffs, and dependencies. In this blog, we’ll explore how unifying inland and port routing with maritime logistics APIs unlocks real-time coordination, smarter routing, and better end-to-end visibility.

Keep reading to discover how shipping route optimization and port-inland logistics integration are reshaping modern maritime supply chains.

The top 10 shipping carriers control about 85% of the ocean freight market, further highlighting how digital leverage like APIs is a competitive differentiator

Two important processes determine the efficiency of cargo flow at the core of the maritime supply chains: the port routing and inland routing. They are profoundly mutually dependent, even though the two are frequently addressed independently of one another.

Port Routing is the handling of containerized cargo in and around seaport surroundings. It includes vessel berthing schedules, the unloading/loading of containers, yard management, gate, and customs clearance. Any single action in the port terminal must be coordinated in a very specific way, since any bottleneck here spills over to the rest of the logistics chain.

Inland Routing, conversely, goes further than the port in the movement of cargo. It links the seaports with other logistical hubs inland, like distribution centers, warehouses, rail yards, and dry ports. The segment deals with inland truck, rail, and barge logistics APIs to make routing decisions to balance time, cost, and capacity constraints.

These two areas are siloed, and therefore the inefficiencies compound when they are combined. For example:

This paradigm is altered by unifying port and inland routing using supply chain APIs. The whole logistics chain is synchronized, with port routing APIs updating the position of container discharge or berth availability in real-time, and inland routing APIs scheduling the transport dynamically. This results in:

In the modern maritime logistics world, where delays may spread out into millions of dollars in demurrage costs or even missed trade opportunities, APIs are no longer a luxury, but a connective tissue that binds together the inland and maritime supply chain ecosystem.

Port routing and inland routing in the architecture of maritime supply chains cannot be considered independent. They are closely integrated and each has a direct bearing on the efficiency, cost, and predictability of the other. Contemporary port routing APIs and inland routing APIs are developed specifically so as to deal with such interdependency such that real-time synchronization is achieved with the entire logistics chain.

To better understand how port and inland routing depend on each other within maritime supply chains, let’s break down their key interconnections:

Inland scheduling is based on precise and updated port schedules about vessel arrival, container discharge and clearance. In the absence of this visibility, inland carriers have to spend some idle hours at terminal gates.

On the other hand, port terminals are reliant on the ability of the inland transport such as trucks, trains or barges to be on time in order to move containers out and prevent congestion in the yard. APIs address this by automating the process of exchanging information including discharge notices, berth assignments and gate-in/gate-out schedules.

The ports have limited yard and berth capacity. In case inland carriers are congested in highways, railways or dry ports, the containers will be held at the terminal and this will be a strain to the storage facilities.

Equally, port delays ripple along the inland routes causing carriers to undergo an expensive rescheduling. The dynamically balanced flows can be realized with supply chain APIs that incorporate the traffic feeds, capacity dashboards and rail schedules which will eliminate overcrowded points on both ends.

Ports form an interface between sea routes and terrestrial routes of transportation. Efficient intermodal handoff Ship-to-port-to-truck/rail- Efficient intermodal handoff needs accuracy between the vessel activities and inland dispatching. This coordination becomes feasible through maritime logistics APIs which allow the smooth operation communication between Terminal Operating System (TOS), rail operators and trucking platforms to schedule pickups and deliveries according to the actual container readiness.

Delays in getting synchronized may bring about demurrage in ports or detention charges of inland carriers. Applications of APIs improve the optimization of shipping routes by coordinating the inland transportation routes with the port discharges which minimizes the number of hours spent on waste and unnecessary expenses. This close connection makes sure that the cargo will flow optimally without much disruption between quay cranes and inland distribution centers.

The point where port routing and inland routing intersect is customs clearance. Inland carriers are not allowed to move containers before clearance is given. Meanwhile, borders or checkpoint delays at inland borders may lead to vessel connections being missed. Document submission and validation are automated by the custom and compliance APIs. They can be used to bridge the regulatory divide between ports and inland logistics providers.

Modern maritime logistics is based on real-time visibility. Port community systems give important updates on the availability of berths and yard congestion as well as availability of the containers. Inland tracking systems submit delivery status and storage updates as well as transit delays. Combining the two using end-to-end supply chain APIs, shippers, logistics providers and port authorities can now have a single source of truth on which they can make decisions.

Cikarang Dry Port is the first and only Integrated Customs Services Zone in Indonesia, which is strategically located to operate as an inland dry port to continue the operation of the most busy seaport in Indonesia, Tanjung Priok at Jakarta. Its operation can be used as a demonstration of how inland and port routing may be integrated together to alleviate congestion, simplify customs, and enhance the overall maritime supply chain efficiency.

Cikarang Dry Port is linked to Tanjung Priok by special freight trains, which carry containers to clear their customs, quarantine, and regulation inspections. This integration has seen container dwell times at the seaport reduced by more than three days to the 2.5 days as mandated by the government, which matches the best practices across the world. This coordination can be achieved by using API to support port scheduling and inland routing because real-time updates about train arrivals, container readiness, and clearance status are received.

Cikarang is not merely a dry port but also a complete logistics hub. It offers bonded warehousing, reefer plugs of cold chain logistics, value-added services, and container yards. Shippers, customs, and logistics providers can work within one platform by using real-time container tracking as well as cloud-based smart port solutions. In this case, inland routing APIs communicate with trucking and rail operators to synchronize multimodal transport movements, and maritime logistics APIs connect these inland transport movements with ship schedules in Tanjung Priok.

Cikarang contributes to the decongestion of the road networks in Jakarta by redirecting customs and storage activities inland, avoiding the congestion of road networks in the seaport area. By coordinating the timing of its downstream logistics, it is able to coordinate the dischargement of port side containers with trucking and the dispatching of rail cars out of the dry port. This is improved by routing APIs, which dynamically adjust the inland dispatches based on the port delays or the traffic conditions.

Cikarang Dry Port explains how physical infrastructures can be integrated with API-enabled digital integration to maximize the routing of the port as well as the inland. To importers, exporters, and logistics providers in the Greater Jakarta industrial corridor, the outcome is quantifiable improvements in:

Simply put, Cikarang is an embodiment of how maritime supply chains can utilize port routing API, inland routing API, and supply chain API to have an integrated port-inland logistics and enable sustainable trade expansion.

The smooth flow of goods is no longer a matter of mere physical infrastructure, be it ports, ships, or a means of transportation (inland). Rather, it is becoming dependent on the digital infrastructure, which links these stakeholders. It is at this point that APIs (Application Programming Interfaces) come in.

APIs are the communication protocols that bring together ports, shipping lines, customs authorities, inland carriers, and logistics providers into one integrated ecosystem. Conventionally, maritime logistics workings were isolated. Port terminals were TOS based, shipping lines based on vessel scheduling systems, customs based on regulatory clearance portals, and inland carriers operated on different systems of trucking or rail. These disconnected systems caused delays, manual coordination, and errors. This is being altered by maritime logistics APIs, port routing APIs, inland routing APIs, and supply chain APIs that allow the real-time sharing of data, process automation, and visibility at the end of the chain.

With APIs, it is possible to draw information directly out of port community systems, shipping line databases, and AIS (Automatic Identification System) feeds. This allows shippers and inland carriers to monitor vessel estimated time of arrival (ETA), container discharges, yard status, and gate movements in real time. By such visibility, downstream planning becomes more certain, and risks of congestion are minimized.

With the port terminal systems and inland transport operators interconnected through APIs, it is possible to release containers immediately after clearing and their physical availability. The inland routing APIs can help trucking and rail companies coordinate their operations with the live information on discharges in the port to ensure that trucks do not spend time waiting at the gates, and rail wagons are not waiting until cargo is loaded.

Customs clearance is one of the largest sources of congestion in maritime supply chains. APIs fill this gap between port systems, customs authorities, and inland dry port facilities. Docs may be digitalized, validated, and cleared in order to eliminate time wastage during processing in case of paperwork mistakes or manual authorizations. As an example, a clearance notification can be used to automatically dispatch inland as soon as the confirmation is received by an automated API.

Routing APIs combine several sources of data, such as the level of traffic congestion, weather, infrastructure restrictions, and carrier capacity, to create improved routes over inland transportation. This enables ports and carriers to align container management to inland real-time operations, minimizing unused miles and expensive re-routing.

APIs combine port, vessel, customs, inland hubs, and carrier data to provide a single perspective of the cargo movement. Status of containers can be tracked by the logistics providers and shippers, starting at berth on the vessel and going all the way to final delivery inland, giving a single point of truth throughout the supply chain. The visibility also improves the communication with customers because, in real time, one can share ETA updates with the end-users.

APIs are also modular, which enables maritime players to increase their digital connectivity without the need to upgrade current systems. A port can be linked to some new inland depot, or a logistics company can add another carrier, and all it needs is to be connected to the corresponding API. This interoperability enables the API to be important in the scaling of maritime supply chains to accommodate larger cargo volumes and wider trade routes.

The APIs serve to provide an interface between the digital communications between the systems in operation at ports (including Terminal Operating Systems (TOS) and Port Community Systems (PCS)) and the communications platforms inland (such as trucking management systems, rail operator platforms, inland depots, warehouse management systems, and so on).

APIs enable real-time digital coordination to align the physical movement of containers with real-time data exchange between these stakeholders by standardizing the exchange of data between them.

To clearly understand the value of connecting port and inland operations through APIs, let’s outline the key benefits of this integration:

The process starts by the TOS of the port releasing APIs that broadcast the operational information like vessel schedules, berth allocation, container discharge orders, and gate-in/gate-out, as well as yard usage. For example, an API might issue an update: “Container ABC123 discharged at 14:00, ready for pickup at Yard C.” This real-time visibility is the foundation for downstream coordination.

These APIs are subscribed to by inland carriers, trucking companies, rail operators, or barge services. They are notified of container readiness in real time, hence only sending vehicles when there is cargo available, avoiding empty trucks at the ports or wagons lying unused at tracks. Portside events are also dynamically chosen by inland routing APIs.

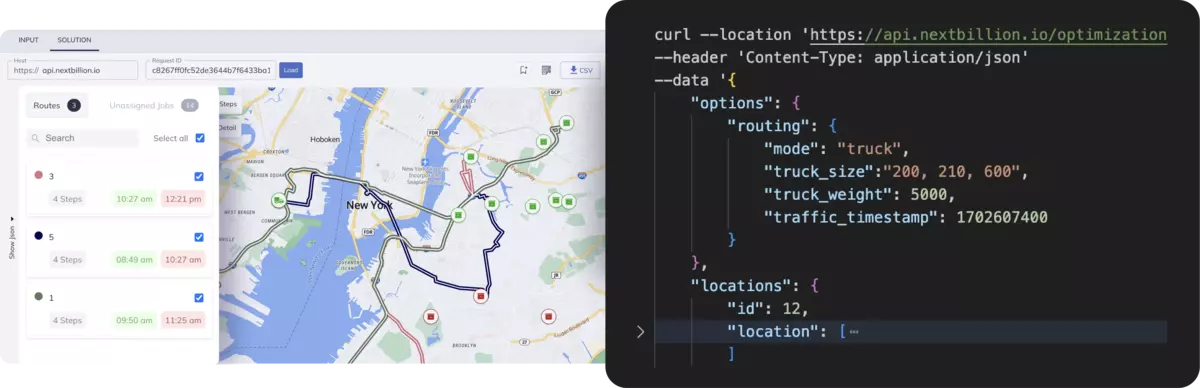

After dispatch confirmation, routing APIs combine real-time traffic information, congestion, and weather information with infrastructure constraints. This makes sure that the transport of the inland cargo will follow the most effective path between the port and inland destinations, minimize the number of wasted miles, and make the most out of delivery time. An example would be a trucking API that would divert shipments around a highway with traffic congestion in real time.

The time when an inland movement can start is frequently dependent on clearance processes. The linkage of the clearance systems of ports, customs authorities, and inland dry ports is through the use of custom and compliance APIs. Once the documents have been approved, an automated message is sent to inland operators, and this initiates container movement without human delays. This saves on the number of bottlenecks due to checkpoints and speeds the pace of cargo movement across the borders.

Integration is not a two-way process. Status updates such as container arrivals, deliveries, unloading clearances, availability of storage facilities, and delivery notifications are sent by the inland depots and carriers to the port community system through APIs. With this feedback loop, ports can predict yard demand, optimize berth scheduling, and plan vessel operations more effectively.

Lastly, shipping companies combine API feeds of ports, customs, inland carriers, and warehouses into centralized visibility solutions. Shippers can have end-to-end visibility of the cargo transport: vessel berthing, container discharge, clearance, inland dispatch, and final delivery. This leads to one source of truth that helps in better planning, less uncertainty, and improved communication with customers

To fully grasp the impact of unifying inland and port routing with APIs, it is important to explore the concrete benefits this integration brings to maritime supply chains:

APIs provide real-time data feeds of port community systems, ship-tracking networks (AIS), customs databases, and onshore transport platforms. This allows shippers, rail operators, and trucking fleets an agreed access to vessel ETA/ETD, container discharge, customs clearance, and inland delivery updates. Real-time updates can be used to schedule in a coordinated manner to ensure that no assets remain idle at the port gates and to minimize the bottlenecks during transfer of goods between ships, ports, and inland networks.

In the case of APIs, routing software can be used to automatically optimize drayage and last-mile delivery schedules. Port routing APIs provide vessel and yard plans as inputs to inland routing APIs, which modify dispatch plans in reaction to cargo readiness. For example, if a vessel discharges containers earlier than planned, APIs notify inland carriers to accelerate dispatch. The system integrates traffic feeds, rail schedules, and shipment priorities to minimize empty miles, maximize asset utilization, and eliminate detention costs.

Maritime logistics relies on several siloed systems, such as TOS in ports, TMS in trucking fleets, WMS in warehouses, and customs clearance portals. APIs serve as a standardization layer in data on these platforms that guarantee that booking data, compliance documents, container IDs, and cargo statuses are both consistent and accessible to interested parties. Such an integration saves manual data entry, removes duplication, and establishes cohesive workflows that help speed up handoffs between port and inland logistics providers.

Unforeseen interruptions such as vessel delays, reallocation of berths, traffic congestion, and customs inspections are situations that can paralyze logistics flows unless they are addressed in real time. APIs of routing can be used to dynamically recalculate inland transport paths and timetables to guarantee cargo flows in response to alterations on the port side. For example, if a customs hold delays container release, APIs automatically push notifications to trucking and rail operators to reallocate resources, avoiding wasted trips and optimizing inland flows.

One of the most useful results of API integration is the end-to-end visibility. APIs enable shippers and providers of logistics to monitor cargo within a vessel berthing to delivery inland by consolidating operational data in centralized dashboards. The real-time ETA, status report, and alerts about disruption are made available to the customers, enhancing the quality of transparency and building trust. It also helps to minimize the use of handwritten check-ins because proactive communication is performed automatically through API-based notifications.

Below are key use cases where routing APIs transform maritime supply chains:

The combination of port routing APIs, inland routing APIs, and supply chain APIs is a revolutionary change to the manner in which maritime logistics is conducted. Rather than fragmented and manual processes, APIs bring together a digitally integrated maritime supply chain ecosystem in which ports, inland carriers, customs authorities, and logistics providers can exchange real-time information as a way to harmonize their operations.

The substantial gains of this unification include less congestion at the ports, reduced demurrage and detention fees, optimized shipping routes, and predictable delivery times in both inland and maritime systems. It also makes supply chains future-proofed, available to scale, interoperable, and able to adopt advanced technologies including IoT, AI-driven route optimization, and blockchain-based compliance systems.

To shippers, exporters, and logistics providers, the message is simple: APIs are no longer optional add-ons. They are the unifying tissue that brings efficiency, strength, and clarity in international trade. With port and inland logistics integration via APIs, businesses can be agile enough to respond to disruptions, well-informed to make better decisions, and competitive enough in the modern global complex marketplace.

Need to have real-time coordination in your supply chain?

Independent of size or scale, NextBillion.ai has developed advanced Port Routing, Inland Routing, and Supply Chain APIs to support logistics networks that are complex and global. From vessel-to-yard synchronization to the optimization of inland trucking, our platform assists business enterprises in cutting down on congestion and operational expenses, while gaining end-to-end visibility throughout their maritime supply chains. Connect with us to know more!

APIs are electronic interconnectors, which unify ports, vessels, inland transport, customs, and logistics platforms. They are automated in container discharge notifications, customs clearance, optimizing routes, and tracking. It bestows real-time visibility and eliminates manual bottlenecks.

Terminal Operating Systems (TOS) and Port Community Systems (PCS) are connected to inland platforms (trucking management systems, rail operator platforms, and warehouse management systems) by APIs. This forms a continuous stream of operational data that coordinates the port activities and inland dispatching to make sure that the movement of cargo between the berth and final delivery is synchronized.

PCS APIs allow the stakeholders to have live information about the vessel schedules, berth allocation, yard congestion, and gate-in/gate-out activities. This visibility enables carriers and logistics providers in the inland to optimize their schedules, minimize wait times, and eliminate bottlenecks at high-risk handoff locations.

APIs reduce the delays incurred during manual coordination between port terminals, inland carriers, and customs authorities by automating communication between departments. As an illustration, routing APIs can change the inland dispatch timetable dynamically based on the delay in the vessels or customs hold-ups, whereas compliance APIs speed up the clearance process by digitizing and validating documents. All of these tools decrease congestion in ports and improve inland routing efficiency.

Yes. APIs are interoperable and modular, implying that new inland depots, customs systems, or carrier platforms can be added and can connect to existing infrastructure without interfering with it. This renders APIs suitable for scaling maritime supply chains to support increased cargo numbers, extended trade routes, and new digital technologies.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.