- BLOG

ETA Accuracy in Maritime + Inland Logistics: A Global Logistics Company Perspective

Published: September 9, 2025

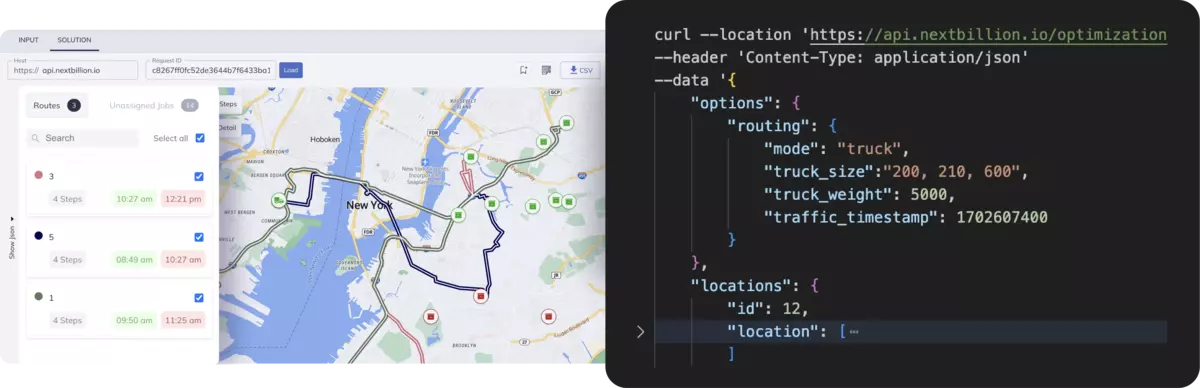

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

What happens when a ship carrying thousands of containers arrives late, or worse, without warning of the delay? The ripple effects can stretch from congested ports and delayed trucking schedules to empty store shelves and halted factory lines. The shipping industry is the essential thread that connects global trade and logistics. It relies on marine shipping, which transports nearly 80% of global commerce. Inland waterway transport is critical to this because it is the most economical, fuel efficient, and environmentally conscious option for transport over road, especially for heavy and bulk cargo such as commodities, agricultural products, and industrial goods.

All of this relies on accuracy in ETA. Therefore, it is more important than ever to get accurate Estimated Time of Arrival (ETA) information about ships that are approaching ports or inland terminals. But in the case of marine businesses, getting accurate data on ETAs is quite challenging. Read on to find out what makes an ETA accurate, and how AI, including both traditional and generative, is changing the future of supply chain visibility.

Estimated Time of Arrival (ETA) is defined as an approximation of the time by which a vehicle, vessel, or shipment is expected to arrive at a specific location. It could be a port, an inland terminal, a warehouse, or the ultimate point of delivery. ETA is, in essence, a simple measure. In reality, however, achieving ETA accuracy in modern logistics means navigating a complicated network of moving variables: the speed of vessels, congestion in ports, customs clearance delays, inland traffic conditions, weather disruptions, and even the working hours of warehouses.

In business sectors like maritime logistics, e-commerce, ride-hailing, and freight forwarding, precise ETAs are not only a matter of convenience. In fact, they are directly tied to operational efficiency, cost control, and customer confidence. For example:

ETAs may be presented in different formats: as specific clock times (e.g., ETA: 3:15 PM), estimated dates (e.g., ETA: April 30), or durations (e.g., ETA: 20 minutes). What truly defines their value, however, is accuracy and context. On simple routes, a straightforward distance/average speed calculation may suffice. But in global supply chains with thousands of interdependent processes, this static approach is no longer adequate.

Today, ETA accuracy is enabled by data-driven, dynamic forecasting. Logistics platforms now continuously update ETAs in near real-time by leveraging live AIS signals, historical voyage patterns, port congestion indexes, inland traffic feeds, and predictive weather modeling. This transforms ETAs from static estimates into actionable intelligence. It further facilitates just-in-time scheduling, reducing demurrage and detention, and ensuring cargo flows with fewer operational surprises.

In short, ETA accuracy has become a strategic facilitator of competitive advantage in maritime and inland logistics, where every hour saved or correctly predicted can translate into millions of dollars saved.

The actions in big ports where a company can have a simple set of operations that include thousands of vessels, containers, and bulk cargo every day are viewed as a well-tuned machine, and any delay can spread to other parts of the supply chain. Scheduling convenience of presence of accurate Estimated Time of Arrival (ETA) is thus not a gimmick in scheduling, but the cornerstone of port efficiency and reliability of international trade.

The port management teams are also able to plan complex operations in advance when ETAs are accurate. This includes:

The outcome is an efficient port call, minimized congestion, improved vessel turnaround time and reduced expensive disruptions. In case the delays are expected, the port authorities have the chance to change the berthing schedules, divert vessels, or stagger the arrival so that the gridlock is avoided, a kind of agility that instills resilience into the system.

However, ETA accuracy has a far-reaching effect on terminal actions. Reliable predictions are essential to other stakeholders throughout the logistics chain:

Another aspect of sustainability in which ETA precision provides quantifiable value is sustainability. Inaccurate ETAs frequently compel ships either to proceed faster than normal to recover the lost time-consuming more fuel-or to wait at the anchor-posts awaiting berths, wasting fuel and emitting more emissions.

Correct and fact based ETAs will enable ships and trucks to operate at the best, fuel efficient speeds, and facilitate just-in-time arrival times, which reduce unnecessary expenditure of energy. In the case of ports, this is the reduced number of vessels circulating in the sea; in the case of shippers, it is the lowering of carbon footprints in multimodal legs of the path.

Research has indicated that by simply reducing the length of the anchorage waits by moderate percentages every year, the emissions of CO2 can be cut by double-digit percentages in a single year. It is of vital importance given that regulators and customers are increasingly considering environmental responsibility.

Ideally, correct ETAs enhance not only operational reliability and cost-efficiency, but also assist logistics participants to align themselves with sustainability objectives and compliance frameworks, making precision a competitive edge.

The following are some of the most notable effects that ripple out into global supply chains when Estimated Time of Arrival (ETA) data is inaccurate:

The increase in container traffic and the unabated demand of goods in the world has strained port infrastructure to the limit. The year 2021 witnessed unprecedented congestion in North American ports where ships were held at anchor for weeks. Not only did these bottlenecks destroy local distribution channels, but also international chains of supply, stockouts in retail stores, late manufacturing inputs and increasing costs of operation among carriers.

One of the biggest sources of this disruption was the absence of quality ETA data. In the absence of precise visibility of vessel arrivals, port authorities had problems in berth allocation, labor scheduling, and handling equipment deployment. This lack of timely and data-driven predictions implied that the congestion would reach the stage of a complete gridlock before the remedial can be taken, and the stakeholders had to go with reactive firefighting tactics rather than planning.

From both an economic and environmental standpoint, inaccurate ETAs translate into significant inefficiencies. Confidence in the ETA predictions enables ships to be in just-in-time arrival modes whereby their speed in cruise is maximized to match the availability of the berths. In the absence of such visibility, ships either speed up unnecessarily, wasting bunker fuel, or they wait in anchorage, wasting fuel as they give off greenhouse gases.

Research has indicated that even a reduction of 12 hours in anchorage waiting times can reduce annual emissions by 188,000 tonnes of CO2 and 1,000 tonnes of NOx, which equates to up to 35% reduction of fuel-related emissions to vessels in some trade routes. These pollutants do not only worsen climate change but also have a negative influence on air quality of port cities and the effects on human health can be quantified through respiratory diseases and early death.

Misaligned ETAs are also a threat to cargo integrity especially of time sensitive and perishable cargo such as agricultural products, pharmaceuticals and refrigerated delivery. The high dwell times would augment the chances of spoilage, trigger insurance claims, demurrage and reputational loss to carriers.

This complexity has been indicated by a legal case that occurred in Brazil in which a shipment of soybeans was spoiled and was awaiting to be discharged in China. The shipowner made the first decision to get damages and demurrage as the financial risks of port delays rise. Although this was overturned subsequently, the case brought out the scrutiny of the systems of law as the shipping schedules in the world become unpredictable.

Unreliable ETAs can trigger a cascade of financial penalties. For instance, ports impose escalating daily charges, for example, $100 per container per day after eight days, potentially doubling thereafter. Meanwhile, global average demurrage costs rose from US $586 to US $664 per container between 2020 and 2022. 2022, demurrage and detention charges across U.S. ports surpassed $67 million, costing shippers 10–15% more in freight-related expenses. Additionally, some ports impose $300+ per container per day during peak periods.

Maritime is also becoming increasingly operated on a just-in-time (JIT) model that seeks to minimize idle berth time and align with inland and last-mile operations. When ETAs are not correct they impact all the downstream and chandlers lose supply windows. Furthermore: maintenance crews are diverted, trucking schedules are reduced, and customs officials have to deal with unforeseen clearance movements.

The smooth workings of this ecosystem are dependent on the common and trusted ETA data to which all stakeholders such as shipowners, suppliers, freight forwarders, port operators, and regulators can synchronize their operations. In its absence, the system returns to inefficiency, delayed and responsive crisis management which compromises competitiveness and customer confidence.

Estimated Time of Arrival (ETA) is not merely a scheduling aid in maritime and inland logistics. In fact, it is the foundation of successful operational planning. However, the ETA deviations are extensive: the deviation of 12-48 hours in the case of maritime transportation and several hours in the case of land transportation is the norm.

This is due to the absence of relation between fixed carrier schedules and nature of supply chain activities. In order to mitigate these problems, logistics stakeholders are shifting to more dynamic forecasting based on data. With real-time feeds, historical information and predictive analytics, ETA predictions are no longer mere fixed approximations but are now updated in real-time to decision grade intelligence.

Data Type | Variables | Role in Forecasting |

Real-Time Vessel & Port Data | AIS signals, congestion, berth availability | Tracks live vessel position, speed, heading, and predicts destination delays dynamically |

Historical Patterns | Seasonal demand surges, recurring bottlenecks | Builds baseline models, recognizes recurring slowdowns, and contextualizes variance |

Inland Traffic & Border Data | Road congestion, customs clearance times | Adjusts final-leg ETA dynamically; reroutes around bottlenecks or delays |

Weather & Environmental Factors | Storms, fog, snow, tides | Predicts impact of conditions on speed, route closures, and safety constraints |

Operational Data | Carrier schedules, yard capacity, crane availability | Anticipates port-side delays; models turnaround and unloading times |

IoT & Customer Data | Container sensors, warehouse hours | Adds cargo-specific insights (e.g., temperature breaches) and aligns ETA with receiver readiness |

Here is how generative AI and AI are proving to be miraculous technologies in the realm of maritime and inland logistics:

AI solutions provide both end-to-end visibility of shipments, integrating fragmented systems in consolidated dashboards. These dashboards monitor the vessel positions, cargo status, and real-time estimated arrival times. An example of a Maritime AI engine is able to examine Automatic Identification System (AIS) indicators, port congestion, and weather projections in order to recalculate ETAs on a few-minute basis.

Logistics managers get actionable information, anomaly notifications and interactive maps that they can use to reroute deliveries or redeploy assets instead of relying on stagnant reports. Gen AI also boosts visibility by translating the intricate datasets into natural language. The operational managers can merely pose the question, which ships will not meet their berthing time this week? and receive clear, data-backed answers.

Information overload is one of the greatest difficulties in logistics. This is addressed by AI so that the teams can concentrate on exceptions, not on the routine events. The AI may be used to prioritize the problems that may disrupt supply chains by classifying, ranking, and filtering anomalies, including delayed vessels, lack of equipment, or missing multimodal connections.

Gen AI goes even further and automatically produces reports and risk assessments and suggests mitigation actions. This change will help stakeholders to be more proactive in the change process than reactive, and this minimizes downtimes and wastages in operations.

Pattern recognition is also the stronger pros of AI and Gen AI, so the risks can be detected earlier than by human operators. Using the live conditions comparison with historical trends, AI will be able to identify upcoming hazards, including overcrowding at terminals, slower than usual vessel traffic or prolonged clearance at the border.

Gen AI transforms such findings into practical advice: redirection of deliveries, trucking capacity redistribution, or informing customers about re-scheduled delivery. This proactive foresight turns the crisis management into strategic resilience, reducing the operational costs and reputational risks.

Demurrage and detention (D&D) is one of the largest cost drivers to global shippers. AI systems track the container dwell time, yard capacity and port turnaround schedule to forecast when containers are vulnerable to attract penalties. AI determines the most cost-effective methods of retrieval or storage by emulating diverse situations.

Gen AI goes through another dimension by automating documentation, creating alerts to procurement teams, and sending messages to customers using understandable language about shipment status. Such a combination not only enhances control over costs, but also enhances transparency and customer confidence.

The NextBillion.ai exhibits the strength of AI at the scale of an enterprise with its API offerings. Here are the most appealing offerings by NextBillion.ai:

Collectively, these APIs can instill AI-based intelligence directly into TMS and fleet management systems and close the divide between predictive analytics and operational implementation.

Grassdoor, a cannabis delivery company in Southern California, faced major challenges in fulfilling its 45-minute delivery promise. Existing mapping solutions were expensive, resource-intensive, and introduced latency that lowered customer satisfaction.

By deploying NextBillion.ai’s large-scale Distance Matrix API on-premise, Grassdoor improved ETA accuracy by 37 percent, reduced latency by 4X, and cut operating expenses by nearly 50 percent. These improvements enabled them to scale deliveries, enhance the customer experience, and strengthen brand trust. This case demonstrates how data-driven ETA forecasting, combined with AI-powered route optimization, can directly transform operational efficiency and financial performance.

These technologies enable autonomous decision-making, scenario modeling, and collaborative supply chain management on a scale previously unimaginable. With regulatory pressure mounting around emissions, AI also optimizes voyages for fuel efficiency, reducing both costs and carbon footprint.

Meanwhile, Gen AI’s natural language capabilities break down technical silos, making complex logistics insights accessible to procurement heads, strategy officers, and operations managers. For enterprises, this means fewer disruptions, more predictable costs, and stronger customer loyalty.

It’s notoriously difficult for maritime businesses to obtain accurate vessel ETA data. 36% of AIS messages don’t include this information, while half of those that do are inaccurate. Accurate ETAs give companies the chance to improve their commercial position, cut costs, attract new customers and have smoother scheduling and fleet operations.

But achieving this precision requires more than basic formulas. It calls for a modern, AI-augmented infrastructure built on high-quality data, predictive models, and real-time decision-making. Whether you’re managing fleets, coordinating global shipments, or optimizing last-mile delivery, the right API tools for accurate ETA turn complexity into clarity and logistics into a competitive advantage.

Contact Nextbillion.ai for a demo and integrate our API solutions with your fleet management system to uncover greater possibilities!

Within logistics, the Estimated Time of Arrival (ETA) is the approximate time that a vehicle, vessel, or other method of transportation will arrive at the destination. It is imperative in the co-ordination of port berthing, dispatching trucks, warehousing and customer expectations. Correct ETAs enhance efficient use of resources and availability of services and incorrect ones create delays, increased cost and supply chain disruption.

Traditionally, ETA is calculated using the simple formula ETA = Departure Time + (Distance ÷ Speed). While useful under ideal conditions, this approach rarely reflects real-world maritime operations. In practice, ETAs are continuously adjusted based on multiple variables, including vessel data such as position, speed, and course, environmental conditions like tides, currents, and weather, and operational factors such as loading, pilotage, and bunkering. Modern ETA systems now rely on AIS signals, weather models, and port feeds, with AI and machine learning improving precision by identifying historical patterns and dynamically recalculating ETAs in real time.

Maritime ETAs may still be off by 12 to 48 hours due to several unpredictable factors. Congestion at ports often results in long queues at anchorage, while weather disruptions such as storms, fog, or rough seas can significantly slow vessel movement. Regulatory and customs delays at ports or borders add further uncertainty, and poor data quality, such as infrequent AIS updates or reliance on manual reporting, reduces accuracy. Inland variability, including trucking schedules or delays at border crossings, can also affect the final delivery timeline. To overcome these challenges, logistics firms are increasingly adopting AI-powered ETA systems that integrate real-time feeds with predictive models. These tools reduce uncertainty, enable just-in-time operations, and deliver measurable improvements in efficiency and customer satisfaction.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.