Table of Contents

- BLOG

Route Optimization Strategies for Efficient Rural Logistics Operations

If someone has only ever worked on routing inside urban or semi-urban environments, then rural logistics will feel like an entirely different world. The assumptions that make urban optimization work: consistent addressing, predictable traffic, real-time signals, map coverage, cellular availability are often missing in rural networks. That does not mean routing is less important. In fact, it is more critical. Because when you cannot rely on infrastructure, your software has to carry the load.

The truth about rural logistics is that it breaks all the rules that typical route optimization tools expect. A delivery point might not even have a formal address. A road might only exist on paper, not on pavement. A driver may need to stop and ask a shopkeeper to locate a house. In these conditions, time windows are not precise, fuel waste is constant, and delivery reliability depends on how well your system can adapt to context rather than control it.

This is where advanced optimization tools begin to show their value. Not because they fix rural logistics instantly, but because they offer a framework that can learn, adjust, and support routing decisions where structured data does not exist. For companies delivering medicine to remote clinics, supplying groceries to far-flung villages, or transporting equipment across broken roads, rural optimization is no longer optional. It is the difference between a system that barely works and one that can scale without breaking.

Understanding Route Optimization

Solving rural logistics begins with understanding what optimization actually means when applied to low-density, high-variability routing environments.

Definition and Basics

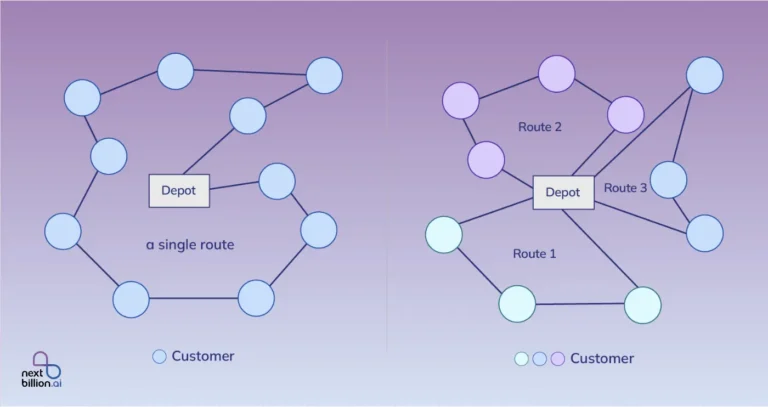

Route optimization in rural logistics is the process of determining the most feasible and efficient travel paths across a widely dispersed delivery network, often without the luxury of complete information. This includes stops that are unmarked, destinations without GPS coordinates, and vehicles that must adjust in the field as real-world conditions unfold.

Unlike urban logistics, where the challenge is density, rural logistics struggles with reach. The gaps between delivery points are larger. The cost of a routing mistake is higher. And the margin for correction is lower. A missed delivery may not just be a lost order. It may mean a missed medicine drop-off, a late repair job, or a delayed supply restock that affects an entire local economy.

Optimization in this context must account for travel time, fuel consumption, road conditions, vehicle durability, and driver fatigue, all without the full visibility that typical systems rely on. It is less about perfecting the plan and more about ensuring the plan will hold up when nothing goes exactly as planned.

Importance and Benefits

Many teams working in rural logistics are still relying on tribal knowledge. Drivers remember which roads flood during the rainy season. Dispatchers write notes on paper maps. Delivery changes are managed through phone calls and WhatsApp messages. While this approach works in pockets, it does not scale. And it cannot provide performance data, optimization history, or service guarantees.

Implementing smart optimization tools in rural environments delivers more than just automation. It replaces guesswork with guidance. A good routing system understands where the gaps are and designs around them. It flags unreachable zones before the vehicle leaves. It tracks average arrival times across routes and adjusts expectations based on actual outcomes. It simplifies decision-making for field teams who would otherwise be left to figure it out alone.

The biggest benefit is consistency. Rural delivery operations are often built on the backs of a few experienced drivers who know every corner of the region. When one of them leaves or retires, the system begins to fall apart. With digital optimization in place, that knowledge is not lost. It becomes part of the system, and the operation continues without collapse.

How Route Optimization Works?

Rural routing is not solved by sending the shortest path to a GPS device. That kind of logic works when the map is clean, the roads are paved, and the signals are always strong. But in rural environments, the map is often incomplete, the conditions change with weather, and even the concept of a fixed address might not apply. Which means optimization must be more than mathematics. It must be grounded in context, flexible enough to respond to what drivers actually face on the ground, and smart enough to learn from failure.

Route Optimization Process Overview

The process starts the same way it does in any routing environment. You collect the stops, define the constraints, map out the possible paths, and then choose the most efficient one based on cost, time, or priority. But in rural routing, each one of those steps becomes harder to define and even harder to trust.

The stops may be vague. A village might only have a common name, no street labels, and no formal property numbers. Constraints are less about timed delivery windows and more about daylight hours, river crossings, or whether the truck can make it up a dirt road after rain. The possible paths are often not known in advance. And what counts as efficient might change mid-route, when the planned shortcut turns out to be impassable.

A strong optimization system does not treat rural data as broken. It treats it as different. It builds routes based on probabilistic reasoning. It leaves room for mid-shift adjustments. It factors in location uncertainty, poor connectivity, and wide variance in travel time. And it works with field feedback, learning which paths are reliable, which locations require manual confirmation, and which zones tend to disrupt plans regardless of what the software predicted.

Optimization is not about precision in this context. It is about resilience. It is about giving the driver a plan that will survive the day, not just look good in the system at 9:00 AM.

Factors Affecting Accuracy

Accuracy is a moving target in rural logistics. Even with the best algorithms, if the input data is flawed, the output will not help. That is not a software problem. That is a reality problem. You cannot optimize a delivery to a house that does not exist on the map. You cannot build an efficient path through a forest if the road appears in satellite imagery but has been washed out for months. And you cannot make promises based on time slots if your driver will need to ask for directions three times before reaching the stop.

That is why rural route optimization relies heavily on data enrichment. Systems need to pull from multiple sources: satellite maps, driver history, crowdsourced landmarks, local government data, and even third-party route logs. It is not about finding one perfect map. It is about layering imperfect maps until the blind spots start to shrink.

The platform must also tolerate missing inputs. If a stop has no GPS coordinate, it should still be allowed on the route. If a driver has poor connectivity, the app should still function offline. If traffic data is unavailable, the system should lean on past route performance to make an informed guess. Accuracy comes not from complete control, but from building a model that holds up when the control is gone.

In the end, rural routing is not solved by pretending it is just like urban routing with fewer vehicles. It is solved by admitting it is a different beast entirely and giving it tools built with that in mind.

Applications of Route Optimization

Rural logistics has always had a reputation for being messy, expensive, and hard to scale. But what people often overlook is that the underlying problem is not the distance or the lack of infrastructure. It is the unpredictability. The variation between what is planned and what actually happens on the road is where operations lose time, money, and trust. That is why rural route optimization matters. Because when done right, it does not only improve routing. It stabilizes the entire network.

Rural Transportation and Supply Chains

The backbone of rural economies depends on reliable movement. That includes food distribution, retail stock replenishment, hardware supply, school materials, and agricultural inputs. These movements are not optional. They support livelihoods. When deliveries fail, they disrupt markets that already operate on thin margins and low redundancy.

Optimized routing helps these supply chains breathe. It allows dispatchers to plan with more confidence. It reduces repeated trips due to missed drops or bad routing logic. It gives drivers a path that works based on conditions, not assumptions. And most importantly, it helps rural suppliers meet commitments consistently, which builds credibility in markets that often run on reputation and word of mouth.

The real gain is not just efficiency. It is reliability. When a village knows the goods will arrive roughly when promised, the entire economic rhythm becomes more stable.

Healthcare and Emergency Services in Remote Areas

Nowhere is rural routing more critical than in healthcare. Medical supply chains often serve communities that are hours from the nearest clinic. When a delivery is late, it is not just an operational failure. It can become a crisis. Vaccines, medications, diagnostic equipment, or even emergency staff movement, all of it depends on routing that works without full data, full roads, or full connectivity.

A traditional system will not survive these conditions. What works instead is an optimization platform that accepts gaps, that plans around incomplete addresses, that can reassign routes based on vehicle health or weather changes, and that syncs with dispatch even over low-bandwidth networks.

These tools also give NGOs and health ministries better visibility. When a mobile clinic team is dispatched into the field, the routing platform can show where delays occurred, how much fuel was consumed, and which zones were not reached. That level of insight allows planners to adjust future missions before they become wasted efforts.

What makes this valuable is not how beautiful the route looks in the system. It is how well that plan holds up in the field, where signals drop and roads vanish.

Agricultural and Utility Service Delivery

Many rural logistics problems are not about product delivery at all. They are about services. A technician visiting farms for sensor calibration. A repair crew restoring electricity after a storm. A vehicle maintenance team checking pumps in irrigation zones. These service patterns are often just as complex as delivery routes but receive even less attention from standard tools.

Optimizing these visits is not just about geography. It is about aligning technician skill with site need. It is about routing in ways that minimize downtime. It is about knowing which service sites are most prone to delay and giving those higher scheduling buffers. And it is about planning routes that match the terrain, the weather, the workload, and the unpredictable ways rural networks behave.

Utility companies that apply rural optimization correctly can reduce site visit delays, cut travel redundancy, and improve reporting accuracy. Farmers get better uptime. Small manufacturers receive more consistent support. And the entire maintenance pipeline runs more predictably.

Route Optimization Tools and Technologies

The right routing software or tools for rural routing are not just smaller versions of urban platforms. They must be designed with the specific challenges of rural operation in mind. That includes map scarcity, offline execution, flexible inputs, and adaptable routing engines that do not break when the data is partial or the road is missing.

Tools for Rural Routing

One of the first things a rural logistics team must consider is whether the platform can operate without full connectivity. If your routing tool needs a constant internet connection to recalculate, it will fail in more than half of the zones where rural vehicles operate.

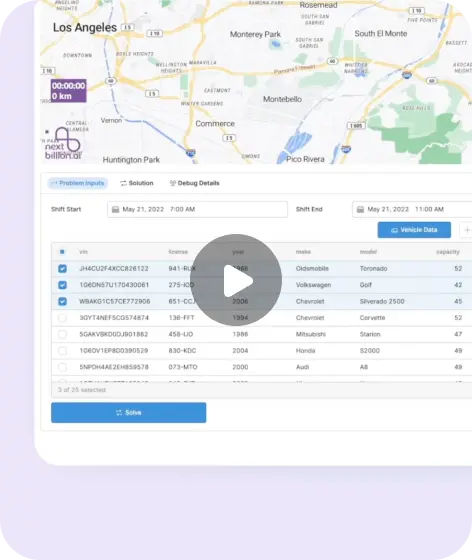

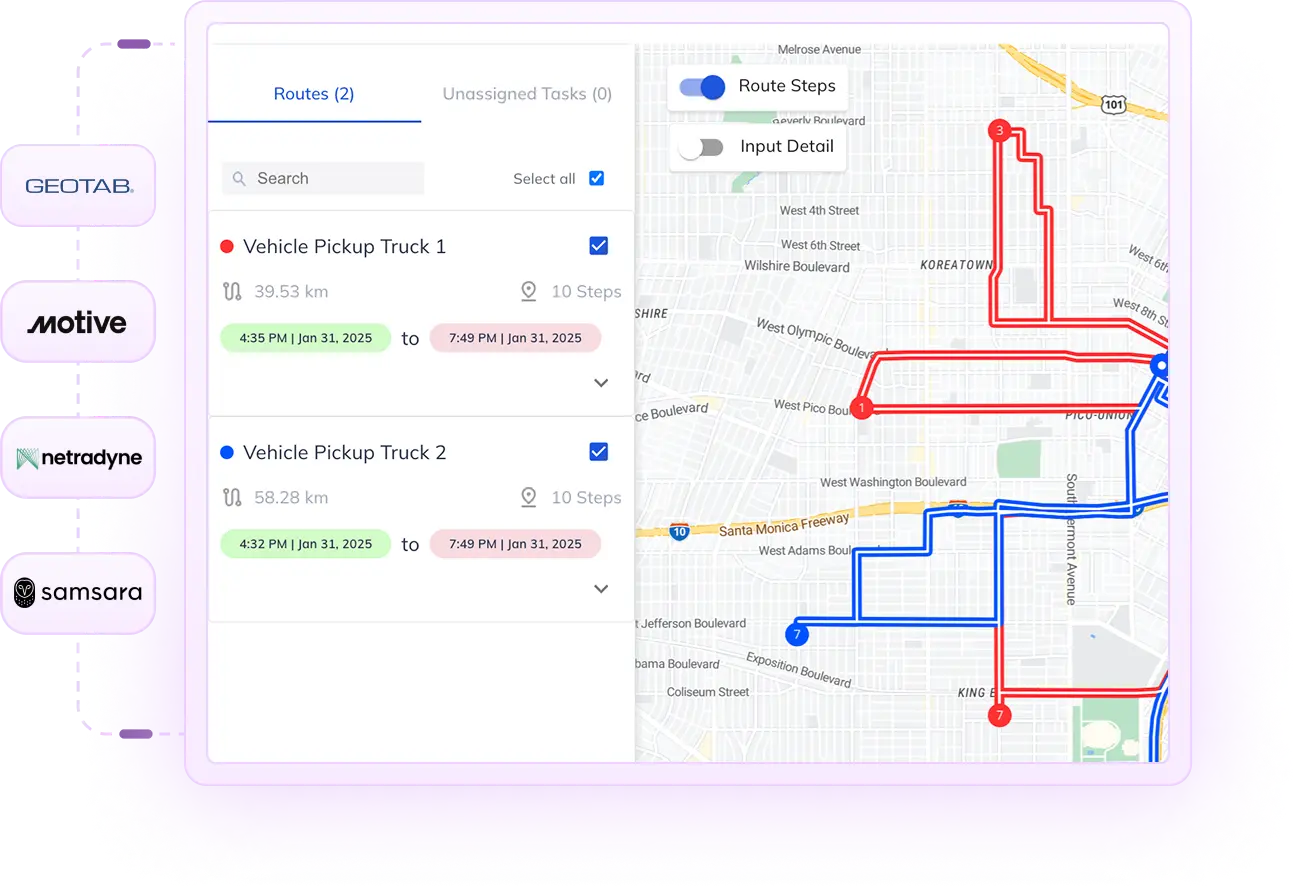

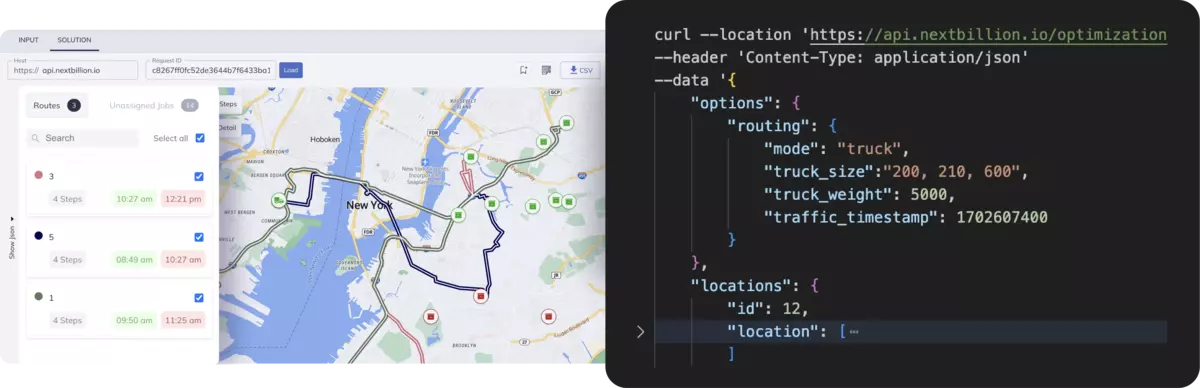

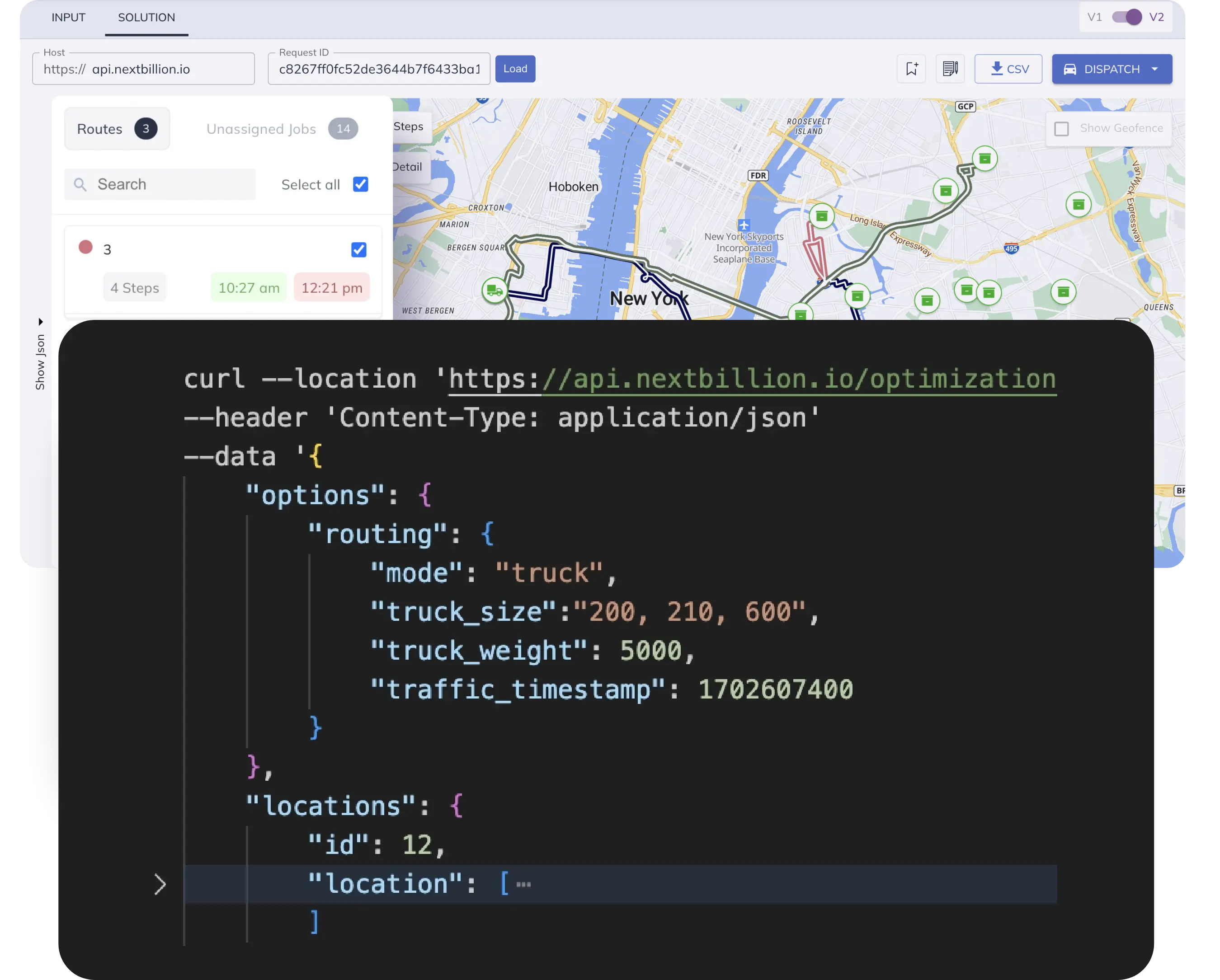

Platforms like Nextbillion.ai offer routing solutions that do not just assume ideal conditions. They are built to survive poor map coverage, low signal, and vague location data. Clients can load region-specific knowledge into the system, including aliases, landmarks, and historical coordinates. That allows for smarter matching even when no street address exists.

Another critical function is editable logic. Rural operations often require business rules that are not obvious to outsiders. For example, a road might be technically available but not safe for a delivery van. A stop might be reachable only during daylight hours. A crossing may close on specific days. Routing tools must allow those constraints to be defined manually or learned from previous attempts. Static systems will fail without that flexibility.

Satellite and Offline Mapping Systems

Standard mapping APIs often do not support the kind of granular data rural routing requires. A village may not be labeled properly. A road may not appear at all. This is where satellite-based routing and offline mapping engines become essential.

Advanced systems can run route calculations using local vector maps stored on the device. They can pull from satellite overlays when vector data is missing. They can cross-reference map tiles with historical path data. This layering is what allows vehicles to stay on path, even when the system cannot show a perfect road.

Offline capability is more than just a backup. It is the main mode for most rural trips. If your drivers lose signal and the app shuts down, your system is not rural ready.

Route Optimization Challenges and Solutions

Every rural logistics team has stories of plans that made perfect sense on the map but collapsed the moment the wheels hit the road. Some of the failures are obvious. Others only become clear after you have wasted fuel, missed three stops, and ended the day with more open tickets than when you started. These challenges are not bugs in the system. They are the reality of rural movement. Solving them means designing tools that expect messiness, not perfection.

Sparse Addresses and Poor Infrastructure

Many rural delivery points do not have formal addresses. A village might have one central name and then rely on descriptive directions like “past the well” or “next to the old tree.” You cannot optimize a stop that your system does not know how to locate. Even when coordinates exist, they may point to the center of a zone rather than the doorstep. That forces drivers to guess or call or turn around. None of that shows up in standard routing analytics. But it is where most time is lost.

Infrastructure problems only multiply the issue. Roads may be unpaved, damaged, or seasonally unusable. A rainstorm can turn a five-minute route into a one-hour detour. The optimization engine must know which paths are passable, which ones degrade under weather, and which ones consistently lead to failed deliveries. That knowledge cannot be found in maps alone. It must be learned from real field data, trip logs, and human feedback.

The best routing systems for rural areas are not the ones with the most advanced geometry. They are the ones that treat delivery points as evolving locations and build resilience into the route from the start.

Lack of Real-Time Data in Remote Areas

Urban optimization relies on a constant flow of real-time data. Traffic speeds, signal strength, dynamic rerouting, GPS position streams, all of it depends on being connected. In rural zones, this assumption breaks. Connectivity is patchy at best and nonexistent at worst. That does not mean the vehicle stops moving. It just means the system must continue working without fresh data.

This is where many tools fail. They pause. They freeze. They wait for a signal to recalculate or sync. A system that does that will not survive more than a day in rural operation. What is needed instead is an offline-first design. Routes must continue adapting based on local inputs, cached conditions, or pre-defined fallback logic. Drivers need the ability to mark stops, report changes, or reroute on their own without losing data.

Real-time intelligence is great. But in rural logistics, delayed intelligence is often the only kind available. The platform must be built to catch up gracefully once the signal returns, without corrupting the operational trail.

Route Optimization Case Studies

Postal Delivery in Rural India

A regional postal network operating across several states in India faced a recurring issue. Packages reached the local distribution center but often sat there for days. The local delivery teams were using fixed routes created years ago, based on staff knowledge and paper records. The maps were outdated. New settlements were not included. And some villages had grown or shifted without updates in the system.

By introducing an optimization engine that allowed manual geo-tagging and regional data injection, the team was able to update thousands of delivery points within two months. Drivers could now follow routes that matched actual terrain and population clusters. Delivery times improved. Missed stops dropped. And overall parcel backlog reduced by almost forty percent. The system did not just speed up the process. It restored trust in the network.

Medical Supply Transport in Remote Regions

An international NGO managing vaccine distribution across Sub-Saharan Africa needed to streamline how doses were moved from regional hubs to local clinics. Routes were built manually each week. But disruptions — fuel shortages, washed-out bridges, clinic rescheduling — meant plans changed daily. The logistics team was spending more time fixing routes than running them.

After switching to an optimization system that could learn from failed trips, the team saw measurable gains. The tool tracked which routes succeeded, which ones faced delays, and which clinics were hardest to reach reliably. Over time, it learned which sequences worked best and began recommending buffer slots, alternate paths, and time-sensitive constraints. Vaccines began arriving within usable windows. Clinics stopped stockpiling as heavily. And field teams finally had a routing plan that reflected the real world, not just a spreadsheet.

Future of Route Optimization

Rural logistics is often seen as a lagging space. But what most people miss is that it is now becoming a testbed for the next generation of resilient optimization systems. Urban networks can afford to fail gracefully. Rural ones cannot. That is why the innovations being built for remote routing today are likely to shape the future of logistics across all sectors.

Expansion of Rural Delivery Networks

As more government and private players push for deeper rural coverage, whether for e-commerce, healthcare, agriculture, or finance, the demand for scalable routing systems will only grow. This expansion will not happen on clean roads with full data. It will happen through overlapping delivery systems, variable access, informal addressing, and inconsistent infrastructure.

Routing platforms will need to evolve from simple schedulers to adaptive planning engines. They will not only decide how to move. They will decide whether to move at all. They will account for weather, service backlog, route fatigue, and multi-purpose trip bundling. This is not optimization in the traditional sense. It is strategic mobility planning.

Tech Innovations for Rural Coverage

Expect to see more routing systems built with hybrid logic. They will combine satellite imagery with crowd-sourced waypoints. They will sync offline-first mobile apps with centralized dispatch platforms. They will allow companies to build their own map overlays and create internal location dictionaries for places that official maps have never listed.

AI will not replace the planner. But it will stop the planner from rebuilding routes from scratch every time something changes. It will help teams focus on exceptions, patterns, and performance, rather than constant firefighting.

And perhaps most importantly, the best tools will not assume they know everything. They will ask for help when they do not. They will prompt the driver. They will log the feedback. They will adapt on the next run.

Conclusion

Rural logistics is not a problem to be solved once. It is an environment to be respected. Every route carries uncertainty. Every delivery depends on more than just distance. Success is not about how perfect the plan looks on paper. It is about how well that plan survives what the road throws at it.

Advanced optimization does not guarantee perfect delivery. But it gives teams a system they can trust when plans fall apart. It gives dispatchers a way to make better decisions. It gives drivers a route that feels more like support and less like guesswork. And it gives communities on the edge of the network a better chance at receiving what they need on time.

The future of rural logistics is not about simplifying the complexity. It is about building tools that operate inside it.

About Author

Bhavisha Bhatia

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.

Ready to get started?

Table of Contents

Related Posts

Ready to get started?

Request a DemoTable of Contents

Subscribe to our Newsletters

Get the best practices for route planning & optimization, delivered to your inbox.

Subscribe