Table of Contents

Table of Contents

When managing logistics for e-commerce and retail deliveries, one of the most common yet challenging scenarios is the need for vehicles to make multiple trips to a depot or fulfillment center throughout the day. Depots are the nerve centers for order processing and inventory management, ensuring that goods are stored, sorted, and dispatched efficiently. But what happens when vehicles, due to capacity constraints, bulk orders, or the need to transport different types of goods, have to return to the depot multiple times in a day? These repeated trips can cause logistical headaches, impact delivery timelines, and strain resources. In this article, I’ll explore why multiple trips to a depot are often necessary, their implications on operations, and strategies to optimize these trips to maintain efficiency and keep costs in check.

E-commerce and Retail Fulfillment

High Order Volumes on Peak Days: During peak shopping periods like Black Friday or Cyber Monday, e-commerce companies experience a significant surge in order volumes. Vehicles making multiple trips back to the depot can pick up additional orders to ensure timely deliveries. This method helps businesses meet high customer expectations without needing a vast fleet, as vehicles are used more efficiently throughout the day.

Grocery Delivery Services

Same-Day Grocery Delivery: Grocery services offering same-day delivery rely on multiple trips to handle the high volume of orders. For instance, a delivery vehicle might complete its morning deliveries and then return to the depot to collect afternoon orders. This approach allows the service to manage a large number of deliveries, keeping produce fresh and meeting customer demands effectively.

Waste Collection Services

Managing Overflow Waste: Waste collection services can use multiple trips to manage large amounts of waste, especially after significant events or seasonal cleanups. Trucks can return to the depot to offload collected waste and pick up new containers, ensuring all waste is processed promptly without the need for additional trucks. This maintains cleanliness and efficiency in waste management.

Pharmaceutical and Medical Supply Distribution

Restocking Pharmacies and Hospitals: In emergencies or during pandemics, hospitals and pharmacies may experience a sudden surge in demand for medical supplies. Vehicles making multiple trips to restock these locations can quickly deliver critical items. This ensures that healthcare facilities receive necessary supplies without delays, supporting timely medical care.

Food and Beverage Distribution

Supplying Multiple Restaurants or Cafes: Food distributors serving multiple restaurants may use multiple trips to deliver the required quantities of fresh produce or beverages. If a restaurant places an additional order, the vehicle can return to the depot to pick up more supplies, ensuring all locations are stocked accurately and promptly.

Agricultural Produce Distribution

Serving Farmers’ Markets or Grocery Chains: Distributors delivering fresh produce to various markets or grocery stores can use multiple trips to maintain the quality and freshness of goods. A vehicle might deliver in the morning and return to pick up additional produce for afternoon deliveries. This ensures that all locations receive high-quality, fresh produce throughout the day.

Home Improvement and Hardware Stores

Delivery of Bulky Items: Home improvement stores often need to deliver large, bulky items like lumber or appliances. Using multiple trips helps manage large orders that exceed the vehicle’s capacity for a single run. This approach ensures that customers receive their full orders promptly, even if it requires several deliveries.

Beverage and Alcohol Distribution

Restocking Bars and Restaurants: Beverage distributors can make multiple trips to ensure that bars and restaurants are consistently stocked. An initial round of deliveries might be made in the morning, with a return trip to the depot for additional supplies as needed. This helps manage high demand, particularly during busy periods like weekends or holidays.

By utilizing multiple trips to a depot, these industries can enhance their operational efficiency, adapt to fluctuating demands, and provide timely service, all while maximizing the use of their existing resources.

How NextBillion.ai Offers Multiple Trips to a Depot

NextBillion.ai’s Route Optimization API is equipped to handle complex logistics scenarios, including multiple trips to a depot. Here’s how we support this feature:

1. Flexible Shipment Configuration

Our API allows users to specify the pickup location as the depot and the drop-off point as the delivery location. This setup ensures that vehicles can make multiple trips to the depot to load up for new deliveries. Each shipment can be broken down into two tasks: pickup and delivery, aligning perfectly with the need for multiple depot visits.

2. Customizable Vehicle Constraints

Users can set various constraints for vehicles, such as costs, capacities, and time windows. This means you can tailor the vehicle’s capabilities and limitations according to your needs:

Costs: Define fixed costs, per-hour costs, per-km costs, or per-order costs.

Capacities: Specify the vehicle’s capacity for different types of goods.

Time Windows: Set the availability times for when the vehicle can perform tasks.

3. Managing Stops and Tasks

While the max_tasks or max_stops constraint limits the total number of stops or tasks a vehicle can complete, it does not restrict how many tasks can be completed between two depot visits. This flexibility allows vehicles to handle a large volume of deliveries by optimizing the number of trips and stops.

4. Optimization Process

During the optimization process, our API evaluates various combinations of orders based on constraints like time windows and vehicle capacities. The optimizer plans each trip to ensure that the maximum number of deliveries are made in each wave before the vehicle returns to the depot for another load.

5. Unlimited Depot Visits

There are no restrictions on the number of depots or trips a vehicle can make. However, the overall limit is 4000 locations or 4000 tasks per request. Since each shipment involves two tasks (pickup and delivery), this limit accommodates a substantial volume of operations.

By leveraging these features, businesses can efficiently manage their logistics operations, handle high delivery volumes, and adapt to dynamic delivery needs.

What is the Feature of Multiple Trips to Depot?

The “multiple trips to depot” feature allows vehicles to return to a depot multiple times for reloading during delivery operations. This capability is essential for optimizing delivery routes and maximizing the number of deliveries a vehicle can complete daily, especially when dealing with constraints like limited vehicle capacity or large order volumes.

With Route Optimization API, this feature is implemented using the “shipments” attribute. Here’s how it works:

Configuring Shipments: When setting up shipments, users can specify the depot location as the pickup point and the delivery location as the drop-off point. This setup allows vehicles to make multiple trips to the depot to load additional inventory for subsequent deliveries.

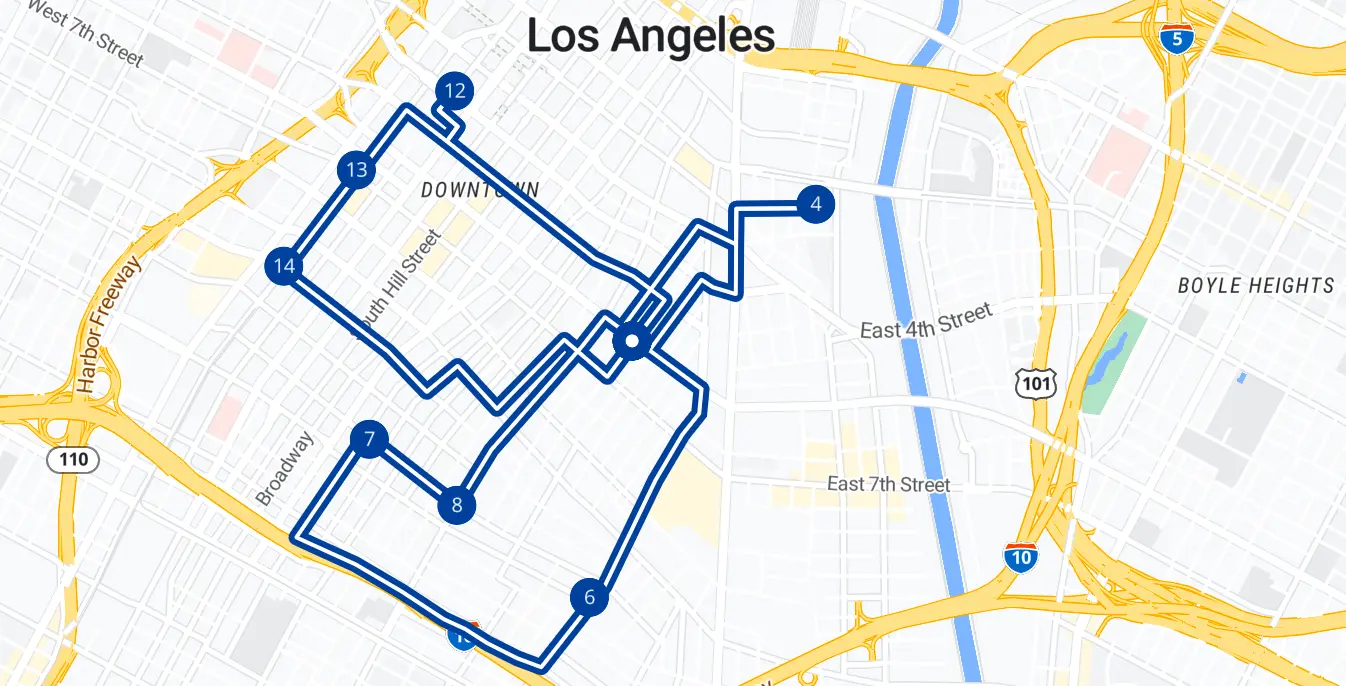

Automatic Route Planning: Once configured, the optimization engine automatically calculates the most efficient routes for the vehicles. It plans routes in a way that maximizes the number of deliveries while minimizing travel time and distance.

By leveraging this feature, businesses can optimize their delivery operations, ensuring that vehicles are utilized to their full capacity and that customer orders are fulfilled more efficiently.

What is the Need for Multiple Trips to Depot?

The ability for vehicles to make multiple trips to a depot is crucial for businesses that aim to handle high delivery volumes, respond to urgent customer demands, and maintain operational flexibility. This feature ensures that fleets are maximized for utilization, enhancing overall delivery efficiency and customer satisfaction. Here’s why multiple trips to a depot are essential:

Maximized Vehicle Utilization

Allowing vehicles to return to a depot for additional loads ensures that every vehicle in the fleet is used to its fullest capacity. Instead of deploying more vehicles, the same vehicle can be used for several trips throughout the day. This approach makes better use of available resources, reducing the need for a larger fleet and optimizing fleet management.

Handling High Delivery Volumes

During peak times, such as holidays or sales events, delivery volumes can spike significantly. Multiple trips to a depot enable businesses to manage these surges without needing more vehicles. This flexibility is essential for maintaining service quality during busy periods, ensuring that all orders are delivered on time despite high demand.

Optimized Routing and Load Balancing

The ability to make multiple trips allows for more efficient routing and load balancing. Routes can be optimized based on the proximity of delivery locations to the depot, minimizing travel time and distance with partial loads. By ensuring that vehicles carry full loads on each trip, the overall number of trips required is minimized, which streamlines operations.

Flexibility in Delivery Planning

Multiple trips provide businesses with greater flexibility in planning and executing deliveries. If there are changes in delivery priorities or urgent orders that need immediate attention, vehicles can easily adjust their routes after returning to the depot. This adaptability is crucial in dynamic environments where delivery needs can change quickly, such as in e-commerce or food delivery services.

Cost Efficiency

While making multiple trips might slightly increase fuel consumption, it significantly reduces other operational costs. These include costs associated with additional vehicles, drivers, and vehicle maintenance. By using the existing fleet more efficiently, businesses can achieve overall cost savings and reduce the need for an expanded fleet.

Enhanced Route Optimization

When vehicles can make multiple trips, route optimization algorithms can plan more accurate and efficient routes. Instead of trying to fit all deliveries into one trip, routes can be optimized for different legs of the journey. This strategy improves overall efficiency by reducing travel time and ensuring timely deliveries.

Adaptability to Real-Time Changes

In situations where there are last-minute changes, such as order cancellations or new orders, the ability to make multiple trips allows for dynamic route adjustments. Vehicles can return to the depot, reload, and adapt their routes without disrupting the entire schedule. This flexibility ensures that new deliveries are accommodated smoothly.

Scalability

As businesses grow, the demand for deliveries typically increases. The ability to make multiple trips allows existing fleets to handle higher delivery volumes without the immediate need to invest in additional vehicles. This scalability supports business growth in a cost-effective manner, enabling businesses to expand their delivery operations as needed.

Overall, enabling multiple trips to a depot is a powerful feature that enhances delivery operations by maximizing resource use, optimizing costs, and providing flexibility to adapt to changing demands.

Comparison of Multiple Trips to Depot vs. Single Trip Strategies

When businesses only use single-trip strategies, they may run into a number of problems and waste time. Here’s how multiple trips to a depot compare to single-trip strategies:

Overloaded Vehicles

With a single-trip strategy, vehicles are often loaded to their maximum capacity to deliver as many orders as possible in one go. This can lead to overloaded vehicles, which results in inefficiencies such as longer delivery times, increased fuel consumption, and higher maintenance costs due to wear and tear. In contrast, a multiple-trip strategy allows for better load distribution, reducing vehicle strain and improving delivery speed.

Inflexibility

A single-trip approach is often rigid and does not easily adapt to changing conditions, such as last-minute orders or urgent deliveries. Once a vehicle is dispatched, there is limited flexibility to accommodate additional deliveries or adjust to route changes. This can result in missed opportunities and lower customer satisfaction. On the other hand, multiple trips provide greater adaptability, allowing businesses to respond dynamically to new orders and changes in delivery priorities.

Higher Costs

Maintaining a single-trip strategy may require a larger fleet to handle peak demand, leading to higher fixed costs in terms of vehicle purchase, maintenance, and staffing. This can be especially costly during non-peak periods when not all vehicles are fully utilized.In contrast, a multiple-trip strategy enables better use of existing vehicles, reducing the need for a larger fleet. This approach lowers operational costs and increases overall cost efficiency by minimizing idle time and maximizing vehicle utilization.

In conclusion, managing multiple trips to a depot effectively requires strategic planning and resource optimization. By utilizing tools and techniques from our interactive guide, you can enhance route efficiency, reduce operational costs, and improve overall productivity. Implement these strategies to streamline your logistics processes and achieve better results in depot management.

About Author

Rishabh Singh

Rishabh Singh is a Freelance Technical Writer at NextBillion.ai. He specializes in Programming, Data analytics and technical consulting, turning complex tech into clear and engaging content.