Table of Contents

Demand planning is one the most important processes in supply chain management that involves forecasting future customer demand for products or services. Its primary goal is to ensure that the right amount of inventory is available at the right time, striking a balance between meeting customer needs and avoiding overstocking or understocking. This process integrates data analytics, collaboration forecasting techniques, and other sophisticated tools to achieve optimal inventory levels and profitability while improving customer satisfaction. In today’s fast-paced and customer-centric business environment, staying ahead of market trends, meeting customer expectations, and managing inventory efficiently are no longer optional, all of them are essential for success. Demand planning enables businesses to achieve this balance by forecasting customer demand to ensure that the right products are delivered in the right quantity at the right time. It involves analyzing historical sales data, market trends, seasonal patterns, promotions, and external factors to predict future demand accurately. Moreover, demand planning bridges the gap between sales, marketing, finance, and supply chain operations to align inventory levels and production with customer needs—minimizing waste, reducing costs, and increasing customer satisfaction.

Components of Demand Planning

Analysis of Historical Data

Finding trends and patterns in past sales data is the first step in demand planning. This enables companies in comprehending historical patterns and precisely forecasting future demand.

Statistical Analysis and Demand Forecasting

Statistical analysis and demand sensing are two powerful approaches used to predict future demand, each leveraging different methodologies and data sources. Statistical methods are used to analyze historical data. It operates on the principle that past trends are often strong indicators of future performance. This method involves complex mathematical processes and requires precise, accurate data factoring in outliers, exclusions, and assumptions to generate reliable supply chain forecasts. On the other hand, demand forecasting enhances traditional forecasting by incorporating new, dynamic data sources such as weather patterns, infectious disease trends, and government reports. By combining these real-time inputs with historical trends and applying AI-driven analytics, demand forecasting detects disruptions and demand influences almost instantaneously, enabling businesses to respond with agility and precision. Together, these methods provide a comprehensive framework for anticipating customer needs in an ever-changing market.

Data Collection

The basis of demand planning is data. This comprises past sales information, market research, campaigns and promotions, economic metrics, and Geopolitical or meteorological factors.

Collaboration

Effective demand planning requires input from various teams such as sales, marketing, finance, operations, and production. This ensures that forecasts align with business goals and market realities

Market Integration

Incorporating external factors like competitor actions, economic shifts, or seasonal changes refines demand forecasts and makes them more robust.

Performance Monitoring

Regularly reviewing forecast accuracy and adjusting plans based on discrepancies between predicted and actual demand ensures continuous improvement.

How Demand Planning works?

The goal of demand planning is to attain and preserve a lean supply equilibrium, where store stocks hold no more goods than what demand requires. It can be particularly difficult to strike the ideal balance between surplus and sufficiency. And although keeping that equilibrium is a key goal of demand planning, so is the ongoing endeavor to influence demand by using promotions wisely.

Accurately predicting demand patterns through the use of demand forecasting methodologies is usually necessary for effective demand planning, which also has other advantages like improved customer satisfaction and business efficiency.

Following is a step-by-step process explained:

- Data Collection: First step in the process is to gather internal data (for example, sales history) and external data (for example, market trends).

- Initial Forecasting: Second step is to use the statistical models or AI tools to create a preliminary forecast. These advanced tools help in forecasting the situation well.

- Collaboration: Third step is to refine forecasts through input from key stakeholders like marketing or sales teams.

- Adjustment: Fourth step is to reconcile forecasts with financial goals and adjust for promotions or new product launches.

- Integration: Lastly, align the final forecast with other supply chain processes like production planning and inventory management.

Benefits of Demand Planning

The following are some of the benefits you can expect from Demand Planning:

- Better Inventory Management: Accurate demand forecasts prevent overstocking and understocking, optimizing warehouse space and reducing holding costs. Reduces errors in predicting customer needs.

- Enhanced Customer Experience: By aligning supply with demand, businesses can fulfill orders quickly and reliably, improving customer loyalty. Ensures products are available when customers need them, improving brand loyalty.

- Increased Profit Margins: Minimizing surplus inventory and avoiding rush production or shipping costs helps control expenses and improve profitability. Helps avoid overstocking (which increases carrying costs) or understocking (which leads to lost sales).

- Improved Supplier Relationships: Clear visibility into future needs enables better negotiation and planning with suppliers.

- Agility and Resilience: Businesses can better respond to sudden market changes, economic shifts, or supply chain disruptions. Identifies potential disruptions early and enables businesses to address them proactively rather than reactively.

- Data Segmentation: Allows businesses to analyze performance across different segments (e.g., locations or product lines), improving decision-making.

Add Your Heading Text Here

Though its merits cannot be doubted, demand planning is a complicated and frequently sensitive process. Even the most advanced systems and experienced planners can be challenged by unforeseen market dynamics and internal constraints. Let’s examine some of the most prevalent issues:

- Data Quality Issues: Demand planning is only as good as the data it’s built on. Poor data quality can take many forms such as unrecorded sales figures, unrecorded returns, or incomplete order history. Data errors through manual inputs, refund and records, or stale product details are caused due to inaccurate information. Faulty input produces false predictions, and these may end up causing stockouts, overstocking, and decision failures. A marginal error in history can accumulate to large-scale operation inefficiencies.

- Market Volatility is another issue when there are sudden changes in market conditions that can disrupt even the most accurate plans. Unexpected shifts in consumer behavior (e.g., trends or viral social media), economic changes, inflation, or recession, supply chain disruptions (e.g., strikes, geopolitical events, pandemics), weather conditions or natural disasters. These events tend to be beyond a company’s control and can make earlier predictions obsolete overnight. Being able to adjust rapidly to them requires steady systems and real-time insight into the data.

- Cross departmental coordination arises when there are misalignments between departments that can hinder effective collaboration. Successful demand planning requires contributions from several departments such as sales (pipeline and promotions), marketing (campaigns and launches), operations (supply chain and inventory), and finance (budgeting and constraints). But silos, miscommunication, or disagreeing KPIs across departments can become stumbling blocks. Sales might overpromise to meet goals, marketing might roll out uncoordinated campaigns, operations might not know about future product changes, and so on.

- Technological Limitations: A few firms continue to depend on spreadsheets or legacy planning tools, which have no automation and scalability, make real-time updates difficult, and are susceptible to human mistake.

With these limitations, companies are not able to make forecasts at the SKU, location, or customer level and therefore missing opportunities or resulting in inefficiency.

Modern solutions like NextBillion.ai and other AI-driven platforms can help mitigate these issues by:

- Enabling real-time data ingestion and analytics

- Promoting cross-departmental integration

- Leveraging AI/ML for predictive forecasting

- Providing agile route and resource adjustments

Demand Planning in Action

Demand planning is a cornerstone of operational success across industries like retail, manufacturing, and e-commerce. It enables businesses to optimize inventory, reduce costs, and meet customer expectations efficiently.

Here’s how demand planning manifests in these sectors:

- Retail: Retailers rely heavily on demand planning to forecast seasonal demand and avoid overproduction or stock shortages. By analyzing historical sales data, market trends, and seasonal patterns, retailers can maintain optimal inventory levels. For example, during the holiday season, accurate demand planning ensures that popular items are sufficiently stocked while minimizing surplus inventory that may require markdowns after the season ends. This not only improves cash flow but also enhances customer satisfaction by ensuring products are available when needed.

- Manufacturing: In manufacturing, demand planning plays a vital role in aligning raw material procurement with production schedules. By forecasting demand accurately, manufacturers can ensure that materials are available without excess waste or delays. This reduces carrying costs and prevents disruptions in production workflows. For instance, a manufacturer preparing for a product launch can use demand planning to anticipate required materials based on projected sales volumes, avoiding costly overstock or understock scenarios.

- E-Commerce: E-commerce businesses face unique challenges during promotional events or peak seasons like Black Friday. Demand planning helps these companies predict order volumes and scale operations accordingly. By leveraging analytics tools and historical data, e-commerce platforms can optimize inventory levels, plan logistics with third-party providers, and avoid costly errors such as over-ordering or stockouts. This ensures smooth operations during high-demand periods while maximizing profit margins.

How can Companies Benefit from NextBillion.ai’s Demand Planning Features

NextBillion.ai can play a pivotal role in demand planning for companies by providing advanced location-based solutions and tools that enhance forecasting, logistics, and operational efficiency.

Here’s how its offerings align with and support demand planning processes:

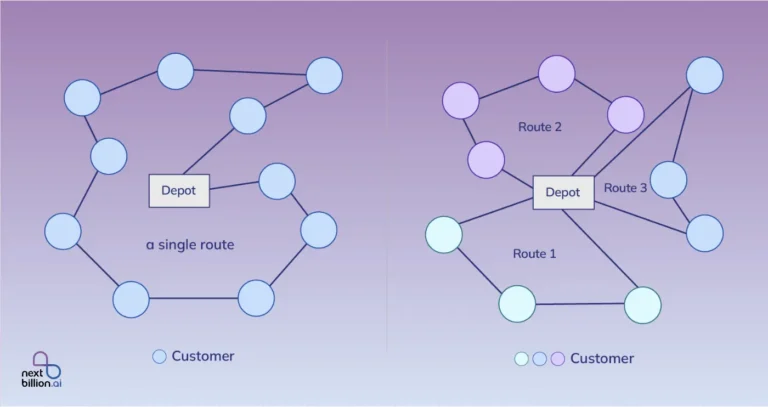

Enhanced Route Optimization for Demand Fulfillment

NextBillion.ai’s Route Optimization API allows businesses to solve complex routing issues by considering over 50 customizable constraints, such as vehicle capacity, delivery time windows, and geographic restrictions. This helps companies streamline their supply chain to meet demand efficiently. By optimizing routes and schedules, businesses can reduce delivery times and costs, ensuring that inventory reaches the right place at the right time.

For more information on APIs, visit Basic Route Optimization.

Real-Time Data Integration for Accurate Forecasting

Demand planning requires accurate forecasting, which is supported by real-time data. NextBillion.ai offers APIs for live tracking and ETA calculations, enabling companies to monitor fleet movements and adjust plans dynamically based on real-time traffic conditions or unexpected disruptions. This integration of real-time data into demand planning ensures that forecasts remain actionable and relevant.

For more information on APIs, visit Live Tracking API.

Intelligent Order Batching and Territory Planning

NextBillion.ai’s Intelligent Order Batching feature clusters orders based on proximity, ETA, and distance, optimizing multi-pickup and multi-drop-off deliveries. Additionally, its Clustering and Isochrone APIs facilitate efficient territory planning by maximizing fleet coverage while minimizing travel times. These capabilities help businesses allocate resources effectively to meet regional demand variations.

For more information on APIs, visit Clustering API.

Custom Mapping for Hyper-Localized Demand Insights

Demand planning often requires a granular understanding of specific regions or customer bases. NextBillion.ai allows companies to build custom maps using proprietary and third-party data. These maps can include unique layers such as no-go zones or service boundaries, enabling businesses to tailor their operations to hyper-local demand patterns.

Predictive Analytics for Asset Utilization

NextBillion.ai leverages historical telemetry data alongside AI-driven tools to predict ETAs and optimize asset utilization. For example, it helps businesses assign vehicles more efficiently, batch orders effectively, and monitor driver behavior. These predictive capabilities improve the alignment of supply with anticipated demand while reducing operational inefficiencies.

Scalable Solutions for Seasonal Demand Peaks

During periods of fluctuating demand such as holiday seasons, NextBillion.ai’s scalable APIs ensure that businesses can handle large routing problems without compromising performance. Its ability to process thousands of stops in seconds supports rapid adjustments in logistics operations to meet sudden spikes in customer demand.

Cost Optimization in Demand Planning

By reducing fuel consumption through shortest-route calculations and minimizing manual intervention with automated scheduling tools, NextBillion.ai helps businesses lower operational costs. This cost efficiency is critical in maintaining profitability while meeting customer demands effectively.

Use Cases Across Industries

- Retail: Optimize last-mile delivery routes during sales events.

- Logistics: Enhance middle-mile delivery with real-time ETA adjustments.

- E-commerce: Improve order batching for faster delivery during peak shopping seasons.

- Ride-Hailing: Reduce cancellations by assigning optimal drivers based on accurate ETAs.

Conclusion

Demand planning is more than just a forecasting tool. It is a strategic capability that empowers businesses to navigate uncertainty, adapt to evolving market trends, and achieve operational excellence. In today’s dynamic market environment, where customer expectations and supply chain complexities are constantly shifting, mastering demand planning offers a significant competitive edge. By leveraging historical data, advanced forecasting tools, and cross-departmental collaboration, businesses can anticipate customer needs with greater accuracy while minimizing costs and disruptions. Whether you’re managing a global supply chain, running a small e-commerce store, or leading a startup, investing in a well-executed demand planning strategy is essential for scalable, sustainable growth and long-term success.

About Author

Prabhavathi Madhusudan

Prabhavathi is a technical writer based in India. She has diverse experience in documentation, spanning more than 10 years with the ability to transform complex concepts into clear, concise, and user-friendly documentation.