- BLOG

Routing for Renewable Energy & Modular Construction Logistics

Published: January 5, 2026

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

Renewable energy and modular construction are no longer niche innovations. They are now central pillars of global infrastructure strategy. Governments, utilities, and private developers are accelerating investments in wind farms, solar parks, battery storage, and prefabricated buildings to meet climate targets, reduce costs, and compress construction timelines.

Yet while headlines focus on megawatts installed or buildings assembled in record time, far less attention is paid to the operational engine that makes all of this possible: logistics routing.

Every wind turbine blade that reaches a remote hillside, every pallet of solar panels delivered to a desert site, and every prefabricated module placed onto an urban construction site depends on routing decisions. These decisions determine:

In renewable energy and modular construction, routing is not a back-office optimization problem. It is a strategic capability that directly affects cost, safety, schedule adherence, and sustainability outcomes.

This article provides a deep dive into routing for renewable energy and modular construction logistics. We will explore:

Wind energy logistics represent one of the most challenging transport scenarios in modern infrastructure. Turbine components are massive, fragile, and highly specialized:

Routing challenges in wind logistics include:

Standard road networks were never designed for turbine components. Routing must account for:

A route that looks feasible on a consumer map may be operationally impossible.

Wind component transport often requires:

Routing decisions must align with regulatory approvals, otherwise deviations can cause costly delays or fines.

Wind farms are typically located in remote areas with:

The “last 10 kilometers” can be more complex than the entire highway journey.

Solar projects rarely involve abnormal loads, but they introduce complexity through volume and coordination.

A utility-scale solar farm may require:

Routing challenges in solar logistics include:

Solar installations often span large areas divided into zones. Deliveries must be optimized across:

Panels and equipment must arrive when crews are ready. Early deliveries cause congestion; late deliveries stall installation.

Solar farms are often located far from urban centers, increasing travel time variability and fuel consumption.

In solar logistics, routing efficiency directly affects installation speed, labor productivity, and overall project economics.

Modular construction compresses traditional construction timelines by shifting work into factories. But this advantage comes at a cost: extreme dependency on logistics precision.

Modular construction sites face:

Routing failures in modular construction can trigger cascading disruptions:

In this context, routing is not about finding the fastest path, it’s about guaranteeing feasibility and precision.

Many organizations initially rely on general-purpose mapping and routing tools. Over time, they discover structural limitations.

Consumer-grade routing focuses on:

Renewable energy and modular construction require routing that understands:

A common failure mode is using:

This disconnect leads to:

Industrial logistics demands one consistent routing logic from planning through execution.

Large infrastructure projects require:

Many traditional tools struggle with scale, flexibility, or cost predictability at this level.

To handle real-world complexity, routing platforms must provide a comprehensive capability set.

Modern routing must optimize across constraints such as:

Optimization is no longer about solving a theoretical shortest path, it is about modeling operational reality.

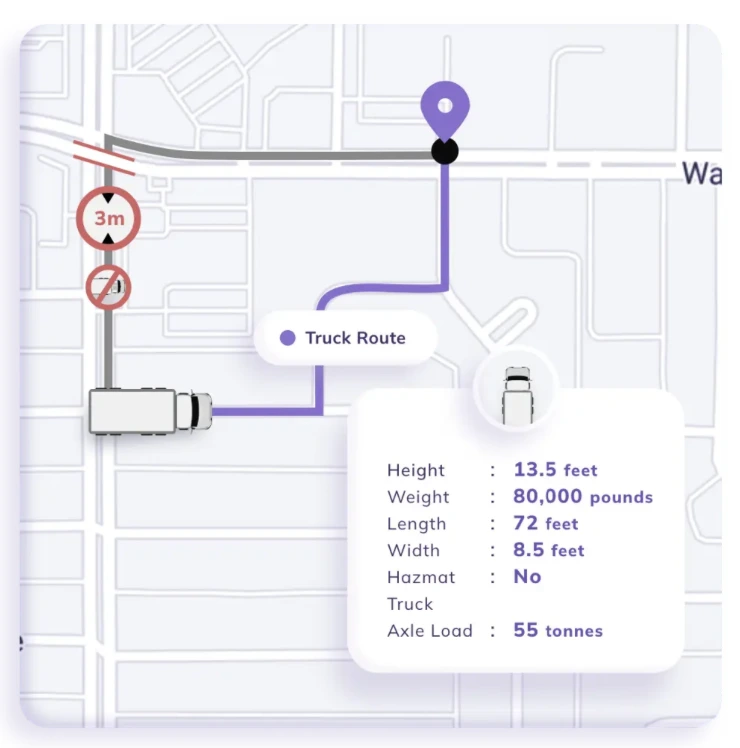

For heavy and oversized loads, routing engines must respect:

Without this, routes may be mathematically optimal but operationally invalid.

Infrastructure logistics depends on answering questions like:

Fast, scalable distance matrix computation is essential for decision-making at scale.

Drivers and escorts need navigation that:

Navigation must be an extension of planning, not a separate consumer app.

Routing platforms become mission-critical systems. They must support:

NextBillion.ai is designed specifically for complex logistics and mobility use cases where constraints, scale, and cost efficiency matter. This makes it particularly well suited for renewable energy and modular construction projects.

NextBillion.ai’s Route Optimization API enables planners to model:

For renewable and modular logistics, this replaces fragile spreadsheets and manual planning with systematic, repeatable optimization.

Nextbillion.ai’s Route Optimization API is a powerful tool that helps businesses optimize their delivery routes to maximize efficiency, save time, and reduce costs.

Refer here for more details on Route Optimization APIs.

NextBillion.ai’s Distance Matrix API supports:

This allows teams to run scenario analysis, compare alternatives, and respond rapidly to change a critical capability for infrastructure projects.

NextBillion.ai’s Distance Matrix API is a powerful tool for computing distances and ETAs between a set of origins and destinations — could be for one-to-many or many-to-many scenarios. Refer here for more details on Route Optimization APIs.

To close the gap between plan and reality, NextBillion.ai offers Navigation SDKs that support:

This ensures drivers follow routes designed for compliance and feasibility, not just convenience.

Infrastructure projects vary widely. NextBillion.ai emphasizes flexibility through:

This makes it suitable for both long-term programs and short, intensive project phases.

Large-scale infrastructure projects demand trust. NextBillion.ai supports enterprise requirements through:

One of the most important distinctions between NextBillion.ai and general-purpose mapping platforms lies in how routing problems are defined and solved. Traditional mapping services primarily optimize for shortest distance or fastest travel time, which works well for consumer navigation and simple delivery use cases. However, renewable energy and modular construction logistics require routing that can simultaneously account for time windows, vehicle capacities, sequencing rules, priority stops, and project-specific constraints. NextBillion.ai is designed around this reality, enabling organizations to encode operational constraints directly into the optimization process. This allows logistics teams to generate routes that are not only efficient on paper, but feasible and compliant in real-world project environments.

In renewable energy and modular construction, routing must prioritize feasibility and regulatory compliance over convenience. Oversized wind turbine components, heavy transformers, and prefabricated modules cannot rely on standard vehicle routing assumptions. Many general mapping platforms offer limited or inconsistent support for truck routing, and often struggle to reliably account for vehicle dimensions, axle weights, restricted roads, or turning limitations. NextBillion.ai, by contrast, treats truck-aware routing as a core capability rather than an edge case. By supporting vehicle dimension constraints and trucking-specific rules, it enables planners to generate routes that align with permit requirements and reduce the risk of costly last-minute rerouting or compliance violations.

Infrastructure projects depend on accurate ETAs across hundreds or thousands of potential routes, depots, and delivery points. General-purpose mapping APIs can technically compute distances and travel times, but costs and performance often become limiting factors at scale. NextBillion.ai is built to handle high-volume distance and ETA calculations as a foundational capability, making it suitable for scenario analysis, what-if planning, and large-scale dispatch decisions. This allows project teams to continuously evaluate alternatives, adjust schedules dynamically, and respond to disruptions without sacrificing performance or predictability.

A common operational risk in complex logistics is the disconnect between route planning and route execution. When planners use one routing logic and drivers navigate using another, deviations become inevitable especially in constrained environments such as urban construction sites or rural wind farm access roads. Many general mapping platforms focus primarily on navigation, leaving organizations to bridge this gap themselves. NextBillion.ai addresses this issue by offering navigation capabilities that are aligned with its planning and optimization logic. This ensures that drivers, escorts, and field teams follow routes that reflect the same constraints and assumptions used during planning, improving ETA reliability, safety, and operational consistency.

Renewable energy and modular construction projects vary widely by geography, regulation, and operational model. General-purpose routing platforms often offer limited flexibility, forcing teams to adapt their processes to the tool rather than the other way around. NextBillion.ai emphasizes customization as a core design principle, allowing organizations to define custom constraints, optimization objectives, and routing rules tailored to each project. This flexibility makes it possible to handle temporary road closures, special access routes, unique sequencing requirements, and evolving project conditions without extensive workarounds.

The cumulative effect of these differences is a matter of focus. General mapping platforms are designed to serve the widest possible range of use cases, from consumer navigation to light logistics. While powerful in their own right, they are not optimized for the extreme constraint density and operational sensitivity of renewable energy and modular construction logistics. NextBillion.ai, on the other hand, is purpose-built for industries where routing is mission-critical infrastructure. Its capabilities align closely with the needs of wind, solar, and modular projects, making it a natural fit for organizations that view routing not as a utility, but as a strategic enabler of sustainable infrastructure delivery.

Advanced routing delivers benefits beyond efficiency:

For renewable energy and modular construction, routing optimization directly supports sustainability goals.

Organizations can adopt advanced routing incrementally:

This phased approach reduces risk while delivering measurable value early.

Renewable energy and modular construction represent the future of infrastructure. But their success depends on logistics systems capable of handling extreme complexity with precision.

Routing is no longer a supporting function, it is core infrastructure.

With its focus on constraint-driven optimization, scalable ETA computation, truck-aware routing, and enterprise readiness, NextBillion.ai provides a routing platform built for the realities of sustainable infrastructure logistics.

Turn routing into a strategic advantage for your renewable or modular projects.

If your logistics teams are struggling with complex routes, missed installation windows, or fragile planning tools, it’s time to move beyond generic routing.

Explore how Nextbillion.ai supports renewable energy and modular construction logistics

Request a demo to see constraint-based routing in action

Build logistics systems that scale with your sustainability ambitions

Prabhavathi is a technical writer based in India. She has diverse experience in documentation, spanning more than 10 years with the ability to transform complex concepts into clear, concise, and user-friendly documentation.