Table of Contents

In 2022, around 95% of the waste generated by the US manufacturing sector was managed through treatment, energy recovery, and recycling, and only 5% was released into the environment. Approximately 7.6 billion tons of industrial solid waste are generated and disposed of at American industrial facilities each year.

Waste disposal and reuse are all associated with environmental sustainability, but the waste collection and dumping trucks deployed on the roads can also contribute to environmental pollution. Running on unoptimized routes can increase fuel consumption, lead to high operational costs, and require more workers to complete the given tasks.

Optimizing collection routes is one critical step toward achieving compliance, ensuring hazardous materials are transported safely and timely, and minimizing all exposure risks for workers and the general public.

Industrial waste route optimization streamlines waste collection routes and enhances operational efficiency, saving fuel costs and reducing travel time. This technology-driven approach supports compliance with EPA and other regulatory standards while aligning with sustainability goals by reducing emissions from excessive transport.

Companies like NextBillion.ai offer industrial waste route optimization systems that tailor routes based on real-time traffic, weather conditions, and priority pickups, ensuring hazardous waste is handled quickly and safely. This is more than just an operational improvement; it’s a proactive step toward safer, more sustainable industrial waste management.

What is Industrial Waste Route Optimization?

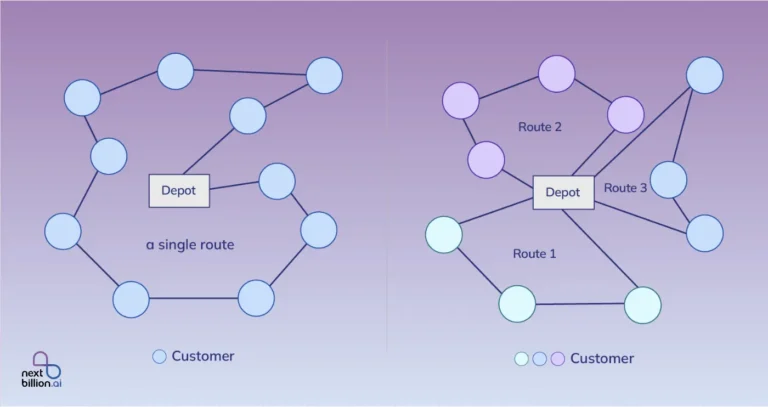

Industrial waste route optimization involves the usage of advanced AI-powered software to optimize waste collection routes and enhance the disposal of hazardous waste. The software considers several parameters, such as location, vehicles, jobs, shipments, and depots, in designing effective routes for waste collection.

Route optimization planner API can be integrated with telematics to adjust industrial waste collection routes based on real-time data dynamically. Optimized routing reduces excessive idling, abrupt braking, and high-speed driving, and telematics can track patterns and trends. It can help managers ensure compliance with driving standards and monitor the driver’s performance.

Moreover, industrial waste comprises chemical waste, like heavy metals (cadmium, mercury, chromium) and waste from petrochemical refining and plastics manufacturing. This waste needs to be disposed of properly and in a timely manner. Finding optimum collection routes manually can be time-consuming and tedious, but software simplifies the task by providing dispatch-ready routes. This ensures that industrial waste reaches the waste processing and disposal facilities for proper disposal of hazardous waste within the given timeframe.

Why do Industries Need Route Optimization in Waste Disposal?

Industrial waste disposal route optimization has become more urgent than ever. The World Bank’s What a Waste 2.0 report forecasts an increase of 70% in global waste production by 2050. For industries that handle hazardous materials and chemicals, effective waste disposal is both a cost management and very stringent hazardous waste disposal regulation compliance issue.

Properly implemented collection routes transform the processes of waste management and make it safer, more cost-effective, and environment-friendly. However, why is route optimization necessary for industries? Here are some major reasons:

1. Reduces Fuel and Operational Costs

The distance travelled by the disposal trucks is significantly reduced, saving most of the fuel expense. This is critical given that operational costs for hazardous waste disposal firms are always increasing.

Due to optimized routes, the trucks can be moved in an organized, efficient manner with less backtracking or idle time. A well-designed hazardous waste disposal process cuts down on unnecessary mileage, which reduces vehicle wear and tear and extends a fleet’s lifespan while lowering operational costs.

2. Enhances Compliance with Regulations

All industries involved in the disposal of hazardous wastes are expected to comply with several hazardous waste disposal regulations set by the Environmental Protection Agency (EPA), like the Resource Conversation and Recovery Act. Regulations often dictate specific disposal procedures, ranging from specific collection centers to timely scheduled collection.

Route optimization enables compliance by helping hazardous waste disposal companies optimize their collection routes according to set regulations. This ensures the safe and prompt disposal of hazardous materials and helps avoid possible contamination or other regulatory actions.

3. Ensures Safe Disposal with Specialized Drivers

Hazardous chemical and medical waste route drivers are trained to adhere to strict handling, containment, and route protocols to prevent accidents or spills during transport. Route optimization lowers exposure time by minimizing the total transit time, which additionally lowers the likelihood of an accident or disaster. Besides, the optimization software creates routes that avoid the high-traffic roads, which ensures public safety.

4. Increases Collection Efficiency

An efficient waste disposal operation defines itself by maximizing productivity with minimal resources. A mapped collection route helps improve the efficiency of the service. Optimized routes enable companies to carry out more pickups within a set time frame without having to compromise on safety.

NextBillion.ai’s route optimization planner uses max_tasks (to mention the number of tasks a vehicle can handle) and max_travel_cost (to cap travel costs which a vehicle can incur). This ensures that the optimizer (API) assigns all the tasks to vehicles within the given time frame as per the vehicles’ capacity.

Real-time route adjustment further improves this efficiency so that industries can dynamically respond to changes in waste volumes produced or emergency waste needs. For instance, with NextBillion.ai’s route optimization API, new stops can be added to the mapped routes without significantly affecting the existing industrial waste collection routes.

5. Supports Environmental Responsibility

Hazardous waste disposal methods can be optimized to achieve environmental objectives because efficient routing decreases the emissions of greenhouse gases that are produced by the consumption of fuel.

This reduces the environmental footprint of waste disposal operations and assists industries in achieving sustainability objectives. For hazardous waste disposal companies looking to maintain green standards, route optimization offers a practical means to incorporate eco-friendly practices.

Route Optimization API in Action: How Does it Work?

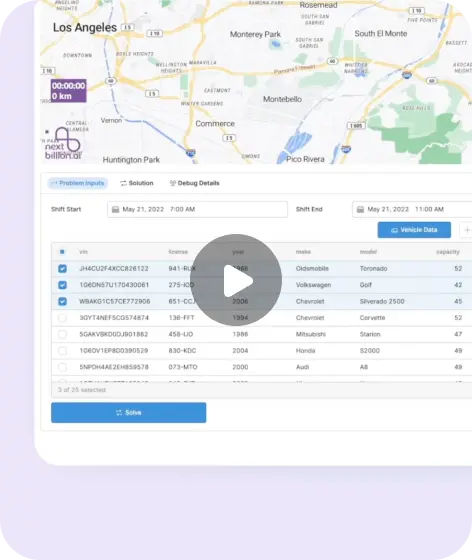

NextBillion.ai Waste Collection API offers advanced capabilities for industrial waste route optimation. The solution can be implemented within a week, and you can start receiving dispatch-ready routes to improve efficiency and productivity in your fleet management. Here’s how it can be implemented:

Step 1. Compile the Necessary Data

First, you will have to compile the necessary data, which will serve as the input for optimizing collection routes. The data includes information about the number of vehicles, depots, vehicle capacity, pick-up locations, type of waste, shift duration, number of zones, and number of vehicles to be deployed in one location.

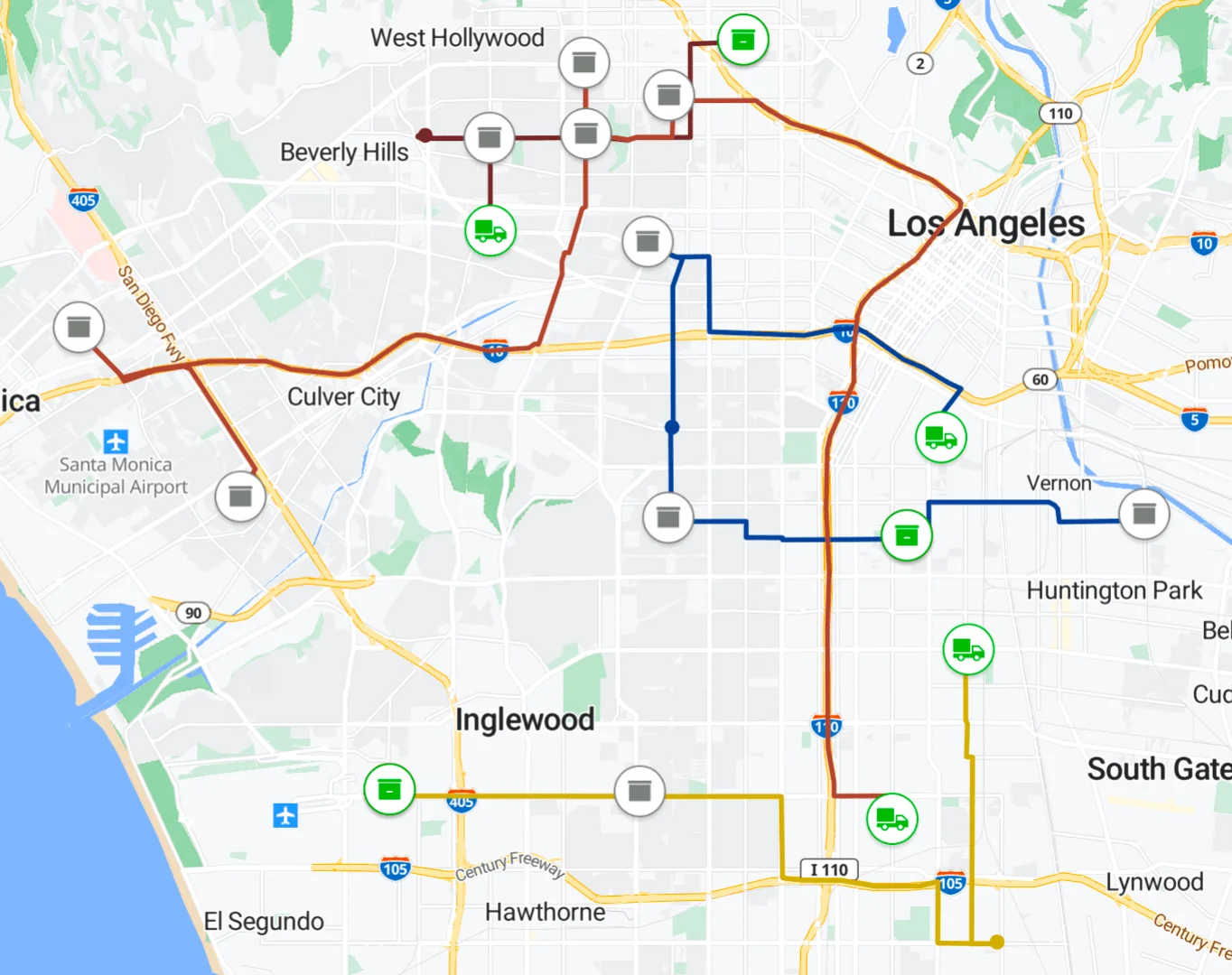

Step 2. Visualize the Data on Map

Once you have entered the data, the entire region will be divided into the specified number of zones, with no zones overlapping with one another. You can visualize the data on the map, like pick-up points and different zones according to their type (like chemical industrial zone or solid waste industrial zone). You can associate a priority number with each zone, such as the chemical industrial zone, which will have a higher priority than the organic waste industrial zone.

Step 3. Allocate the Trucks

Now, enter the data about your garbage collection fleet. Mention the trucks’ capacity and also the waste bin or garbage pick-up point capacity so the collection routes can be optimized accordingly without any truck going under or over its capacity limit. Also, mention how many trucks can be allocated per zone.

Step 4. Run the Route Optimization API

Send the data to the API and it will process all the data and provide the route considering the parameters. The API will generate the results for all the trucks in the fleet and assign them tasks zone-wise.

During optimization, there are chances that some places are left and remain unassigned. With the re-optimization feature for unassigned tasks, the optimization API can be run again, and the trucks which remain unassigned will be assigned to the places that were left. In this way, all the pick-up points are covered, and your fleet is deployed efficiently.

How Route Optimization Planner Solve Major Challenges in Industrial Waste Route Optimization?

Routes optimization within industrial waste management is multifaceted and has inherent challenges that prevent efficiency. Apart from mapping collection points, planning considers intricate sequencing as a way of cutting more time and fuel consumption in the process. Here are some major challenges in optimizing waste collection routes:

1. Inability to Determine Optimal Collection Routes

Manual route mapping works perfectly for small companies. However, when the regions being serviced become larger, it becomes tough to consider variables such as traffic conditions and restricted areas. Sometimes, due to a lack of effective route optimization, regions will overlap, wasting too much time and resources.

Route optimization APIs, like NextBillion.ai’s, create routes considering upto 50 different parameters. Also, it employs a multi-faceted approach which combines spatial analysis as well. It divides the entire region into zones by generating a set of non-intersecting polygons using Voronoi tessellation.

2. Unpredictable Traffic Conditions

Waste management firms based in cities are primarily exposed to unpredictable flow patterns since rush hour, accidents, and events converge people in a community. Such unpredictability makes it difficult to determine a certain route, thus slowing the collection process and undermining efficiency.

NextBillion.ai’s Distance Matrix API supports avoid parameter, which ensures that the route avoids ferries, tolls, and highways.

3. Higher Repair and Maintenance Costs

The higher the service areas are, the greater the mileage collection vehicles will need to accumulate, resulting in higher wear and tear. Inefficient routing results in “deadhead miles,” which are unproductive miles travelled between collection points. This inefficiency results in more fuel consumption and maintenance expenses because vehicles become more frequent to service.

NextBillion.ai supports the travel_cost parameter, which can be used to estimate the solution’s cost. It suggests the route with a lower cost value. If Duration is used, then the driving time of all routes is calculated, and a smaller drive time is preferred. Other options, like Distance and Air Distance, are also available.

4. Waste Type and Load Optimization

Industrial waste comprises different types, such as solid, chemical, e-waste, and organic waste. Each has a distinct treatment procedure and handling process. When planning the routes manually, it becomes difficult to consider all the constraints and create an optimum industrial waste collection route according to waste type and vehicle load capacity.

The route optimization planner has a multi-dimensional capacity parameter, which can be used to describe different types of quantities. A single vehicle can carry different types of quantities, like 10 cubic meters for volume, 1000 kg for weight, or it can hold upto 6 large waste bins on a single route. As per the use case, you can identify the right parameter to define, and the API will optimize the routes accordingly to ensure that no vehicle carries weight more than its defined capacity.

5. Complex Navigation

Industrial facilities and disposal areas have restrictions, such as strict access times, limited/unlimited loading zones, and capacity constraints. Industrial areas have an intricate layout, with certain areas labelled as red zones and no-access zones. So, computing routes considering all these factors also becomes difficult, and a lot of back-and-forths are required with industrial facility members to get an accurate idea about the facility and which zones to avoid.

The route optimization API can be customized, and you can add custom route restrictions to comply with local regulations and meet your unique requirements. NextBillion.ai’s Waste Collection solution also includes a Navigation API, which provides the driver with necessary information while driving regarding the roads and industrial areas to avoid.

The Bottom Line

Industrial waste collection route optimization is not only a needed strategy in industries’ operational activities but also forms an integral part of the larger perspective of environmental sustainability.

Advanced technologies and route optimization planners can effectively reduce costs, enhance compliance with regulations, and ensure the safe disposal of hazardous materials. This aligns with global efforts to minimize waste generation and negative environmental impact, aiming for a cleaner and more sustainable future.

Leverage the full potential of route optimization for your waste management operations through a partnership with NextBillion.ai. They offer leading-edge solutions that provide all the tools you need to streamline your waste disposal processes while ensuring compliance and sustainability. Learn how their innovative route optimization API can transform your industrial waste management strategy and help contribute to a greener planet with NextBillion.ai today!

About Author

Bhavisha Bhatia

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.