- BLOG

How to Reduce Failed Beverage Deliveries? 7 Proven Strategies

Published: November 18, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

What’s more frustrating than a delivery arriving late? A delivery that never arrives at all. In the beverage sector, a missed delivery does not only imply wasted fuel, but also empty shelves in a bar, loss of trust in your company by a retailer, and lost money to your company. In the case of heavy products, perishable goods, regulated goods, and time-sensitive goods, each unsuccessful attempt is more severe than in any other logistics sector.

The good news, though, is that most of the delivery failures can be prevented, and the winning companies of today are not the ones making more deliveries, but rather the ones making smarter, more data-driven deliveries.

We will first discuss the established strategies before dissecting them and how the best distributors are correcting the situation. Prefer the full deep-dive? You can read the complete version of this guide here.

The most effective supply chain may collapse at the final mile. In beverage logistics, the failure of delivery is not often a one-factor problem; it is often a combination of operational blind spots, the constraints of a customer, and the reality of unpredictability. The most frequently occurring breakdowns occur due to:

The beverage and alcohol logistics do not operate under the same principles as the parcel, grocery, or retail delivery. These goods are large, delicate, controlled, and time-sensitive, and demand special treatment, transportation, time, and papers. Consequently, the performance of delivery becomes much more susceptible to disruption; a single stop being delayed early on the route can spread the effect to all the other stops.

The following are the most important operational factors that render beverage deliveries to be unique and challenging:

Orders of beverages are physically heavy to carry. A small order can have a weight of 20-40 kg, and a pallet containing a bar or a distributor can be over a ton. Beverage drivers, as opposed to parcel drivers, have to deal with:

Each of the stops needs additional time, effort, and machinery.

Outcome: Increased dwell time, reduced number of stops in a route, and a sharp increment in chances of operating late.

A variety of drinks are temperature-controlled products: craft beer, wine, dairy-based beverages, kombucha, and carbonated drinks all need certain cold-chain conditions. This adds new dimensions of complexity:

Outcome: This will lead to increased monitoring, increased risk points, and increased delays in case of any cooling problem.

Majority of beverage customers do not have the opportunity to get goods at any time of the day. Their delivery time frames are small and no negotiation:

Miss the window, and the order is not “late”, it becomes undeliverable.

Result: One missed slot→forced reschedule→ripple effect on the rest of the route.

Glass bottles, canned drinks, kegs, and carbonated items cannot be treated in the manner of parcels. A single pothole, a single sharp turn, or one improper stack can lead to:

Drivers usually need to pause on the way to re-assess the stability of loads, and this introduces additional time.

Result: More handling care→slower delivery cycle→ higher failure rate during peak demand.

Delivery of beverages is not often a drop delivery. The customers are returning often:

This in-built reverse logistics further complicates and increases the time required in every stop; drivers cannot simply drop and run.

Result: Extra loading, scanning, and verification→ longer stop times→reduced delivery efficiency.

Demand of beverages is predictable, though unevenly distributed:

The fleet capacity is not always increased at the same rate as the demand.

Result: Too many orders + too few vehicles/drivers+ late routes and missed deliveries.

Not all trucks will be able to transport drinks. Many loads require:

In case of a breakdown of one of the specialized trucks, it cannot be substituted by an ordinary van.

Result: Limited backup options→scheduling bottlenecks→preventable delays turn into failed deliveries.

Here are 7 proven strategies you can apply right now to dramatically reduce delivery failures and keep every route running on schedule:

The current beverage distribution cannot be based on fixed routes or next-day planning. Traffic, delivery time, vehicle limits, and customer priorities fluctuate during the day, and it is clear that routing has to be recalculated, not just pre-calculated. Live optimization ensures that delays in routes are corrected before they become delivery failures, safeguarding schedules and fleet efficiency.

In order to transform routing into smart and not reactive, operations should consider:

The Delivery Management System is the core layer of command in beverage logistics, which substitutes manual coordination with a single, data-driven workflow. A DMS does not require drivers, dispatchers, and customers to work independently, but coordinates all moving components: orders, routes, vehicles, proof of delivery, real-time location, and customer communication. This provides the visibility to remove avoidable failures and address exceptions while the route is still active.

A high-functioning DMS should support:

Successful delivery does not rely only on routing, but also on matching the correct vehicle to the correct job. Sending a large truck into a small urban area, using a non-refrigerated vehicle for cold drinks, or dispatching a truck in poor condition are all likely to result in failed delivery. Fleet assignment should be deliberate, and fleet readiness should be proactive rather than reactive.

Fleet planning needs:

The route is not the most common reason why beverage deliveries fail, but rather the destination. Beverage drivers cannot walk a block to find a lost unit number or loading dock, unlike parcel drivers. Wrong, missing, or unverified addresses trigger automatic reschedules because the truck must continue. Address intelligence must be fixed at the point of origin, before dispatch, not after failure.

Workflows must contain the following to eliminate address failures:

The majority of delivery failures do not occur due to operational errors but due to customer unavailability. If customers are not informed, cannot plan for receiving, or do not know the exact arrival time, the order may be rejected even when delivered on time. Automated communication fills this gap and ensures both logistical and customer readiness.

Important communication checkpoints include:

Freight delivery of beverages is not generic freight delivery. Each type of product, such as glass bottles, pressurized cans, keg systems, or temperature-sensitive drinks, requires specific loading, stacking, and handling knowledge. Training reduces damage, compliance violations, and rejected orders. A skilled workforce converts delivery from a risk factor into a competitive advantage.

Training areas that directly reduce delivery failures:

Consumption of beverages is not uniform but cyclical, seasonal, and event-driven. Predictive analytics allows companies to forecast spikes before they occur instead of reacting after routes and fleets are already overloaded. Instead of planning for average days, planners can prepare for real demand patterns, such as holiday surges, summer peaks, sporting events, or weekend volume imbalances.

Predictive planning enables:

The price of inefficiency is amplified in beverage and alcohol logistics. Each extra kilometer traveled, each hour of traffic jam, each missed delivery time costs more fuel, overtime working of drivers, risk of product quality, unhappy customers, and, finally, loss of revenue. Beverage delivery is limited by the weight of the products, the sensitivity of handling, loading dock time, temperature control, and rigid delivery times, unlike parcel logistics.

This is the reason why, nowadays, distributors are not relying on manual route planning systems and are shifting to algorithm-based, constraint-sensitive route optimization packages. The change is not simply regarding quicker routing, the change is regarding the transformation of the delivery operations to be not reactive but anticipatory so that vehicles, timing, product demands, and customer limitations are all automatically coordinated. An efficient route optimization engine minimizes unsuccessful deliveries, enhances fleet efficiency, workload.

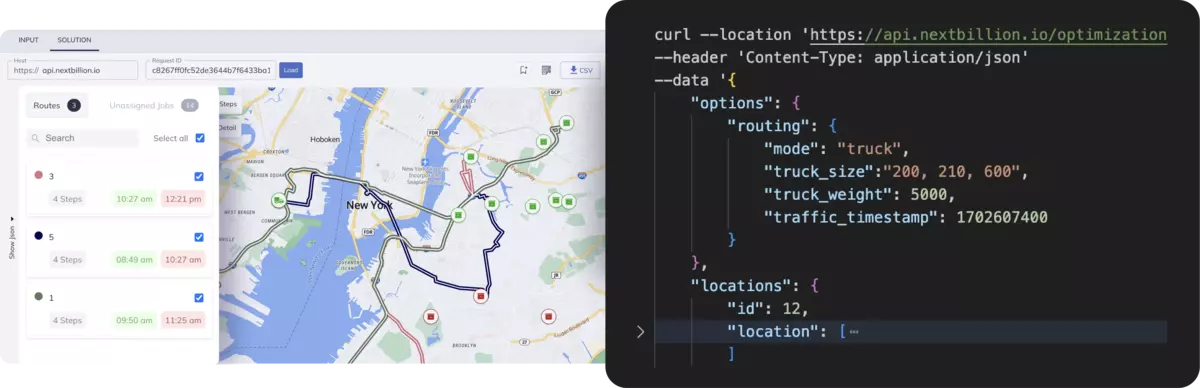

The Route Optimization API of NextBillion.ai is designed based on real-world delivery constraints, rather than on hypothetical mapping. It is organized to handle logistics where time windows, vehicle capabilities, product types, and customer rules all matter simultaneously, exactly the scenario in beverage and alcohol distribution.

Instead of producing one static “best route,” the system continuously adapts: to late orders, road restrictions, vehicle breakdowns, temperature-sensitive loads, or regulatory requirements. It optimizes not just where a truck goes, but when, with what load, using which vehicle, and in what sequence.

Below is how core modules directly improve beverage delivery outcomes:

Jobs and Vehicle Shift Timings: The API enables stipulated delivery time limits and driver shift restrictions.

Why it matters:

The majority of beverage clients have limited time to receive goods (bars prior to opening, retail stock windows, hotel docks prior to 11 a.m.). Time-window routing eliminates the problem of “driver arrived, customer closed” failures that are among the leading causes of rescheduling and loss of revenue.

Order Grouping: Orders that are nearby can be grouped into one optimized stop.

Why it helps:

Beverage routes are commonly used to serve compact business blocks (restaurants on a street, convenience stores in a block). Formation of groups minimizes mileage, unloading time, idle time, and traffic exposure, key contributors to delayed routes.

Zone-Based Allocations: The API enables the limitation of vehicles to specific areas with geofences.

Why it helps:

Fridge trucks or heavy trucks are unable to access every location. Zone-based allocation eliminates the possibility of a loaded truck entering a low-clearance, weight-restricted, or dock-limited zone, reroutes, fines, and unsuccessful attempts.

Re-Optimizing a Route Plan: Routes are recalculated during daytime when things change.

Why it helps:

Beverage logistics is not static. A customer can request an urgent restock, a keg return can be requested, a driver can report a breakdown, or a venue can close down on short notice. Re-optimization eliminates partial collapse of routes and ensures that the rest of the stops remain on time.

Vehicle: Maximum Travel Cost / Maximum Tasks

Allows the restriction of stops or overall travel per vehicle.

Why it helps:

Overload in drivers or trucks will cause overtime expenses, fatigue mistakes, loss of temperature, or even failed final delivery. Establishing thresholds will make sure that no vehicle is overscheduled, and compliance as well as the quality of service is not compromised.

Volume and Cargo Orientation 3D

The API takes into account loading dimensions, stacking patterns, and fragile orientation.

Why it helps:

Beverage cargo is not abstract; glass bottles, pressurized cans, kegs, crates, and cartons all have different stacking behavior. 3D planning eliminates product damage, load repositioning, and rejected delivery due to bad loading behavior.

Task Sequencing / Task Interrelations

Permits the establishment of rules like task B should occur after task A.

Why it helps: Popular beverage regulations are:

Soft Constraints (Flexible Time Windows)

Time windows may be considered as flexible rather than absolute.

Why it helps:

The delivery of beverages in real-world conditions is rarely strict. A customer could receive the delivery 15 minutes early or late, or traffic could delay a stop by a few minutes. In minor violations, soft constraints prevent the stop from being marked as failed.

The beverage and alcohol supply chain leaves no room for uncertainty. Each missed time slot, damaged pallet, and low-performing route will have a ripple effect that will reach cost, customer loyalty, and brand credibility. The winning companies of today are not the ones that deliver more, but the ones that deliver with precision, informed by data, powered by automation, and informed by intelligent routing decisions. The changing demand patterns, decreasing delivery windows, and increasing operational constraints can no longer be supported by manual planning and disjointed tools to support modern distribution networks.

Optimization of routes is not anymore a technical upgrade, but a competitive advantage. With the ability to adapt in real time, enforce delivery rules, manage fleet constraints, and protect product integrity, the right platform becomes the difference between reactive logistics and predictable, profitable last-mile execution.

If you are willing to remove the failures of deliveries, enhance the efficiency of fleets, and innovate the beverage distribution processes, learn how NextBillion.ai can assist in changing your routing processes.

Get a demo or begin your free trial at NextBillion.ai.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.