Table of Contents

When we think about logistics and trucking, most of us picture trucks moving goods from point A to point B. But there’s an entire science behind ensuring those trucks don’t come back empty. That’s where backhauling comes in.

In this guide, I’ll walk you through the concept of backhauling, why it’s essential for optimizing operations, reducing costs, and minimizing carbon footprints. If you’re in the logistics industry or just curious about how the supply chain works more efficiently, keep reading to discover the strategies and benefits of backhauling.

What Does Backhaul Mean?

Backhauling is a way to save money and time by cutting down on deadhead miles in logistics. Adding pickup stops to delivery and transportation routes is part of the process. Pick-up stops are planned into the route so that they work with the amount of cargo that needs to be picked up and the available truck. This keeps trucks full so that they don’t have to travel extra miles going anywhere, and it also makes sure that truckloads don’t go over the payload capacity of the truck.

Backhauling is used by well-known clothing stores like H&M and ZARA as part of their reverse logistics. Tote boxes that can be used again and again are used to ship clothes from the distribution center to each store. Every store gets a shipment and takes the goods out of the boxes. After that, the boxes are stacked and left alone. Whenever the next shipment comes by truck, the store takes it and gives the driver the empty tote boxes from the last delivery to take back to the distribution center. Backhauling is used on the way back to the distribution center.

Before you use backhauling as a strategy in your own logistics, you should take a look at your current routes and count how much cargo is dropped off at each stop. After that, figure out how much cargo the driver needs to pick up at each stop. You also need to figure out which routes will put trucks in each pickup location by measuring how far each one is. Then, add the new stop to the route and match trucks to pick up spots. Remember, though, that trucks can only pick up cargo after delivering enough for the new cargo to fit on the truck.

Advantages of Backhauling

Backhauling can help your bottom line by saving you money and making your business run more smoothly. To win over customers, it also helps your business be better for the environment.

Save money

Big clothing store Macy’s cut costs by getting rid of 11% of its empty miles through backhauling. This was possible for the store because backhauling speeds up loading and transporting.

This means that you only hire as many workers as you need, which helps keep costs down. You can also use your vehicles more efficiently when you backhoe, which cuts down on wear and tear and makes the vehicles last longer.

Maximize the efficiency of operations

Backhauling makes things run more smoothly by planning loads better, which makes better use of trucks to get the most deliveries done. More businesses can offer their services to more people, which improves the quality of service and lets customers get help right away.

As an example, let’s say a truck driver who works as a freelancer is hired to bring a big load of goods from Virginia to New York. When the driver gets to New York, they have to pick up one item to take back to Virginia, but they will still have room in their car for more stuff.

The truck driver can say that they will be taking things to Virginia and have room for more things. This means that the driver can make more money by doing more jobs, without having to make more trips or buy more vehicles.

Make sustainability better

A recent study found that 60% of consumers are influenced by sustainability when they decide what to buy. To win over customers, companies that move goods, especially those in the transportation and trucking industry—which is responsible for 14% of the world’s greenhouse gas emissions—should make their operations more environmentally friendly.

Backhauling and other green logistics strategies are the best ways to make your business eco-friendly. That’s because backhauling cuts down on the time that vehicles are sitting idle on the road, which lowers greenhouse gas emissions. These emissions are a major cause of climate change.

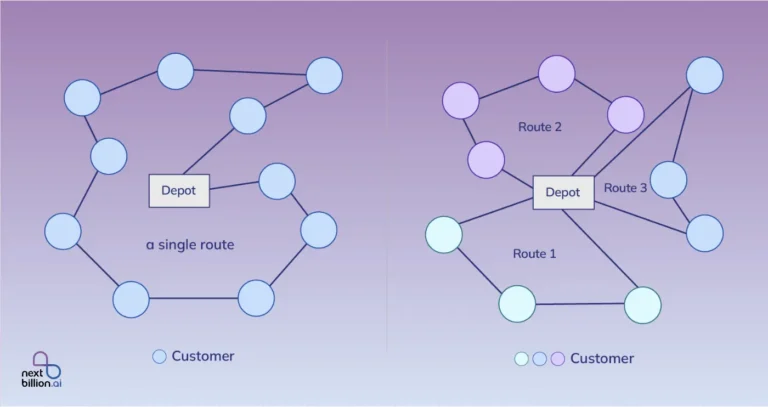

Comparing Internal and External Backhauling

Two kinds of backhaul exist: internal and external. Next, we’ll talk about what each type of backhauling is and why companies use them.

Internal backhauling

Companies use internal backhauling as a logistics method to move their own goods. A simple example of this is services that bring milk to your door. The milkman brings new milk and then picks up the empty bottles to take back to the base so they can be filled again. That which H&M does as part of its outbound logistics is also an example of internal backhauling.

External backhauling

External backhauling is when shippers, like for-hire trucking companies, move goods that belong to other companies. Private fleets and reverse logistics companies do this kind of backhauling most of the time because many large companies outsource their shipping and transportation to save money. One example of this is semi-truck drivers who are hired by businesses to move individual trailers. Trucking companies that bring food from a farm or distribution center to a supermarket are another example.

Backhauling Challenges

Backhauling, while beneficial, presents several challenges that logistics companies must navigate to maximize its advantages. Here are some key challenges:

Route Optimization: Finding return loads that align with the truck’s route can be complex. If the return trip is too far off the original route, the cost savings from backhauling may be negated by increased fuel and time expenses.

Scheduling Conflicts: Coordinating pickup times for backhauls can be tricky. Delays in the initial delivery or misalignment in schedules between the drop-off and pickup points can disrupt the efficiency of the entire operation.

Regulatory Restrictions: Different regions may have varying regulations regarding load limits, routes, and permits. Ensuring compliance while attempting to maximize load efficiency can be a significant hurdle.

Load Compatibility: Not all goods are compatible with each other. Certain backhauls might require specific types of trailers or conditions that limit the type of cargo that can be transported on the return trip.

Market Volatility: The availability of backhaul loads can fluctuate due to market demand, seasonal changes, or economic conditions. This unpredictability can make it challenging to consistently secure return loads, leading to periods where trucks may still run empty.

Data Management: Efficient backhauling relies heavily on accurate and real-time data. Companies must invest in technology and systems that can track available loads, match them with the right trucks, and coordinate schedules seamlessly. Inadequate data management can lead to missed opportunities and inefficiencies.

Overcoming these challenges requires a strategic approach, advanced route planning, and often, investment in technology to ensure that backhauling contributes positively to the overall logistics operation.

Integrating backhauling into logistics and truck route planning can significantly improve efficiency and reduce costs. However, backhaul planning comes with challenges such as matching delivery and pickup locations, aligning time windows, balancing vehicle capacities, and managing costs.

NextBillion.ai’s Route Optimization API offers a comprehensive solution to address these challenges by allowing logistics companies to define and configure vehicle routes with high precision. Below is a breakdown of how the API’s parameters can be utilized to tackle backhaul challenges effectively:

1. Vehicle Constraints Management

- Start and End Points (start_index, end_index, start_depot_ids, end_depot_ids): To plan backhauls, vehicles need to start and end at specific locations or depots. These parameters help define the starting and ending points, allowing for efficient pickups and drop-offs along the route. For example, setting start_depot_ids and end_depot_ids can ensure that vehicles only handle jobs that are aligned with their starting and ending depots, optimizing the backhaul route.

- Capacity and Alternative Configurations (capacity, alternative_capacities): Vehicle capacity constraints are crucial for planning both forward and backhaul loads. The capacity attribute allows you to define multidimensional capacities for each vehicle. With alternative_capacities, you can specify alternate configurations, enabling the system to optimize routes based on load distribution between deliveries and pickups, thereby ensuring no vehicle travels empty.

- Maximum Tasks and Stops (max_tasks, max_stops): Setting a limit on the number of tasks (max_tasks) and stops (max_stops) per vehicle helps control the complexity of the route, ensuring that the vehicle can handle all assigned pickups and deliveries within a feasible route.

2. Time Window Alignment

One of the significant challenges in backhaul planning is aligning delivery and pickup times to avoid delays and maximize vehicle utilization. The time_window parameter allows for specifying the available time periods for each vehicle:

- Single Time Window Per Vehicle (time_window): By defining a single time window for each vehicle’s availability, you can align pickup and delivery schedules within the permissible operational hours. This flexibility ensures that vehicles perform tasks without violating time constraints, a critical factor in backhaul planning where synchronization between multiple jobs is needed.

- Driver Breaks and Layover Configurations (break, drive_time_layover_config): To comply with regulations and ensure driver safety, the API offers break and drive_time_layover_config options. These allow you to configure breaks and layovers, balancing driving times and required rests, which is essential in multi-leg backhaul routes.

3. Optimizing Costs and Reducing Empty Miles

Cost efficiency is one of the primary goals of backhaul planning. By reducing empty miles (the distance traveled without cargo), businesses can achieve significant savings. The costs object in the API allows for fine-tuned cost management:

- Cost Definition Parameters (fixed, per_hour, per_km, per_order): These parameters help in defining cost attributes for each vehicle. For example, per_km cost can be adjusted to reflect the cost savings of backhaul routes compared to standard delivery routes. By configuring these costs, the API optimizes vehicle assignments to reduce overall costs.

- Avoidance Strategies (avoid): Using the avoid parameter, you can set route preferences to avoid tolls, highways, or certain areas, which can help in reducing additional costs associated with long-distance routes. For backhaul optimization, this can mean avoiding routes that incur higher operational costs when an alternative, more cost-effective route is available.

4. Managing Routing Constraints

The flexibility of the Route Optimization API also extends to managing routing constraints that can impact backhaul effectiveness:

- Zone Management (allowed_zones, restricted_zones): Using allowed_zones and restricted_zones, you can define areas where vehicles are permitted or restricted. This ensures that vehicles are not routed through undesired areas, helping in planning backhaul routes that are more efficient and compliant with specific regional or operational restrictions.

- Truck Configuration (truck_size, truck_weight, hazmat_type): These parameters allow you to specify the size, weight, and type of goods being transported. This is particularly useful for planning backhauls involving hazardous materials or bulky items that require specific routes or vehicle types.

5. Grouping and Task Prioritization

To further enhance backhaul efficiency, the API offers grouping capabilities that allow for logical task grouping and prioritization:

Order and Route Grouping (order_grouping, route_grouping): The order_grouping parameter enables grouping nearby tasks, treating them as one stop and avoiding unnecessary travel between close locations. Similarly, route_grouping allows for prioritizing tasks within a zone, ensuring all tasks in one area are completed before moving to another zone, which is crucial for optimizing backhaul routes.

NextBillion.ai’s Route Optimization API provides a robust framework for integrating backhauling into logistics and truck route planning. By leveraging its flexible parameters—ranging from vehicle constraints and time windows to cost management and zone control—logistics companies can overcome backhaul challenges effectively. This not only results in reduced operational costs but also maximizes resource utilization, leading to a more efficient and sustainable logistics network.

About Author

Rishabh Singh

Rishabh Singh is a Freelance Technical Writer at NextBillion.ai. He specializes in Programming, Data analytics and technical consulting, turning complex tech into clear and engaging content.