- BLOG

AI-Powered Route Optimization for Fleets (2025 Edition)

Published: June 26, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Table of Contents

Anyone who has ever been responsible for moving more than five vehicles across more than twenty stops knows that routing, despite how it looks in theory, does not behave logically once the day actually begins. It does not matter how perfect the route seemed when it left the system. A single blocked road, a sick driver, a late pickup, or a customer who suddenly steps away from their delivery window is enough to set off a cascade of delays that no spreadsheet can recover from in time.

This is why AI-powered route optimization has gone from being an experiment to becoming a necessity for modern fleet operations. It is not about calculating the shortest path anymore. That kind of routing is outdated. Today, optimization must consider how time, traffic, geography, vehicle constraints, delivery priorities, and real-time data interact across an entire day. The system must not only be able to build a route. It must be able to fix it once things begin to break, because they always do.

Companies that continue to rely on manual planning, outdated fleet software, or basic point-to-point tools are not just leaving efficiency on the table. They are burning time, losing margin, increasing driver stress, and creating conditions that cannot scale. Meanwhile, those who have implemented AI-based optimization engines are gaining a level of control that has been impossible until now. This shift is not cosmetic. It is structural. It is the difference between reacting to problems and designing around them before they happen.

The principles that guide AI-based routing are not new. What is new is the ability to apply them in real time across a constantly shifting set of variables.

At its foundation, route optimization refers to the process of determining the most effective path for a fleet to follow when executing multiple stops under defined operational constraints. These constraints may include time windows, driver schedules, vehicle capacities, service durations, and legal road restrictions. On paper, it sounds like a math problem. In practice, it behaves more like a moving target that requires constant recalibration.

A traditional routing engine builds a static plan based on rules. An AI-powered system builds a dynamic framework that adapts its decisions as conditions change. It does not just measure distance or drive time. It observes historical behavior, identifies risks, adjusts to live inputs, and generates routing logic that reflects how your specific fleet tends to perform under stress. This is what separates a routing tool from an operational intelligence layer.

No two fleets are the same. A system that performs well for a courier company in a European city may completely collapse in an informal addressing environment in Southeast Asia. AI allows a routing engine to localize its behavior, to prioritize based on regional norms, and to avoid the false confidence of generic models that look accurate but perform poorly once vehicles are on the road.

A plan that does not hold up under pressure is not a plan. It is a liability disguised as a strategy. Without strong routing in place, fleets operate with guesswork. Dispatchers rely on personal intuition. Drivers waste time rerouting themselves in the field. Missed time windows become normal. Overtime hours pile up. And nobody in the operation knows what went wrong until it is already too late to fix it.

The value of AI-based optimization is not only in faster routes. It is in the consistency of execution. When a system understands how the fleet behaves, it can design around real-world obstacles before they appear. A delayed delivery does not require five phone calls. A last-minute stop does not crash the entire plan. The software rebalances the sequence, respects the constraints, and gives the driver a new version of the day that still works.

This kind of resilience compounds. Fuel consumption decreases. Vehicle usage improves. Support tickets from angry customers drop. Route planners stop patching broken schedules and start improving system performance. And drivers regain trust in the instructions they are given, because those instructions are no longer made in a vacuum.

While the front end of a routing system often appears simple, the architecture underneath must handle complex decision-making, live data integration, and multi-dimensional tradeoffs.

The first step in any optimization cycle is data ingestion. The system cannot generate reliable plans unless it is working with accurate, timely inputs. These inputs typically include stop locations, customer delivery preferences, driver availability, vehicle specifications, traffic data, service time estimates, and external constraints such as toll restrictions or city-level delivery zones.

Once this data is collected, the engine applies operational constraints. These are not optional parameters. They are hard rules that must be honored. A driver may only be certified to handle hazardous material. A certain street may be closed during school hours. A specific customer may require an afternoon delivery due to access regulations. Without incorporating these factors, a route may look efficient on a screen but fail in the field.

After constraint mapping is complete, the engine begins to compute routing options. AI models help by simulating thousands of route permutations and scoring them based on objectives such as shortest time, lowest fuel usage, or fewest vehicle miles traveled. These models are not just optimizing for output. They are optimizing for survivability. That means the route is not only fast, but also likely to succeed under pressure.

The system continues to monitor the route as it is being executed. It receives live updates from GPS trackers, driver mobile devices, and traffic feeds. When an incident occurs, such as a delay, a skipped stop, or a schedule change, the engine recalculates the plan and pushes updated instructions without requiring manual dispatcher intervention.

Routing accuracy begins with input quality. No system, regardless of how advanced its AI is, can build a valid plan if the underlying data is flawed. Inaccurate addresses, missing delivery instructions, outdated driver rosters, and vague vehicle limits will always degrade route performance. These gaps must be closed through clean integrations with source systems such as order management tools, fleet telematics, and customer platforms.

Another influence is geographic context. A generic system that applies the same logic in a suburban United States region as it does in a congested urban center in India is going to fail in one of those scenarios. Local delivery behavior, road infrastructure, vehicle class restrictions, and customer expectations all vary by region. The system must be trained to behave differently based on that context.

The last critical factor is the presence of feedback loops. A routing engine that does not learn from its mistakes will repeat them. Modern AI-based optimizers should be trained on both success and failure data. They should be able to recognize when certain stops always take longer, when certain drivers always fall behind, or when certain delivery zones routinely produce route failure. Without that loop, the system never improves. With it, the routes get smarter every week.

The value of intelligent routing does not begin and end at delivery. It extends across any operation that involves the coordinated movement of assets, whether those assets are packages, people, equipment, or service teams. What makes modern route optimization powerful is not just the ability to reduce travel time. It is the ability to rewire how a business handles spatial decisions under real-world pressure.

For freight and logistics operators, the cost of inefficiency scales fast. A poorly routed delivery route does not just mean an extra ten kilometers of fuel. It means a missed dock time, a delayed return trip, a cascading disruption to the next day’s load, and eventually a customer who no longer trusts your timeline. Multiply that by a few dozen vehicles and the impact is massive.

What AI-based optimization brings to logistics is not just better routes, but smarter decisions before those routes are dispatched. It adjusts loads to match road realities. It balances vehicle use so that no truck is underutilized. It predicts where bottlenecks are likely and plans around them. And most importantly, it keeps plans live. If the situation changes at 2:00 PM, the system is not relying on the choices made at 6:00 AM. It recalculates, communicates, and keeps everything moving forward.

This level of control does not just benefit the dispatcher. It reduces stress on the driver, lowers fuel burn, and gives operations teams a level of foresight that was impossible with static plans.

E-commerce has turned delivery from a logistics challenge into a customer experience promise. When a shopper clicks “buy,” they are not just ordering a product. They are expecting a timeline, a level of transparency, and a resolution path in case anything goes wrong. In last-mile delivery, routing is no longer back-office logic. It is front-line execution.

Urban last-mile deliveries often involve dense delivery zones, unpredictable traffic, narrow time windows, building access complications, and constant schedule changes. If the routing engine cannot absorb all of that and still produce a reliable plan, the operation will collapse by mid-shift.

AI-based routing in this context shines because it clusters stops intelligently. It aligns vehicle capabilities with package types. It minimizes building reentries. It adapts to building-level patterns such as when service elevators become available or when business delivery times shift based on weekday patterns.

The real breakthrough is not only the initial plan, but the mid-route corrections. If a stop cancels, the system does not simply drop it. It adjusts the sequence, reassesses timing, updates the driver’s instructions, and keeps customer notifications accurate. This kind of flexibility is the difference between a well-oiled operation and a fire drill at every shift.

Field service is often overlooked in routing discussions, yet it presents one of the most demanding environments for real-time optimization. Technicians are not just moving between stops. They are performing time-sensitive tasks that depend on skills, parts, client availability, safety checks, and access coordination. Routing in this space must consider much more than just drive time.

If a technician arrives early but cannot start work because the site is still locked, that is wasted time. If the second stop takes longer due to an unexpected repair, the rest of the day collapses. Traditional routing engines fail here because they do not account for field service complexity. AI-based optimizers do.

By learning from actual service durations, technician performance, part usage patterns, and historical traffic on those routes, the system can begin to build routes that not only match the distance between jobs but also match the reality of what those jobs actually require. It can sequence high-priority tickets to the beginning of the shift. It can avoid sending junior staff into high-complexity locations. It can update estimated arrival times based on live repair durations without needing constant dispatcher input.

This is not only better for operational efficiency. It also helps retain staff. Technicians who are not routed across town five times in a day for ten-minute jobs experience less burnout. That kind of improvement is not visible on a route map, but it shows up in service quality and workforce stability.

The routing market has become increasingly saturated with tools promising optimization. But not every route optimization tool is built for the kind of complexity that real fleets deal with on a daily basis. Choosing the right platform is no longer about features alone. It is about whether technology can learn, scale, and deliver under stress.

Several platforms have emerged as serious contenders in the routing space. Their strengths lie not just in core features, but in how they handle unpredictability.

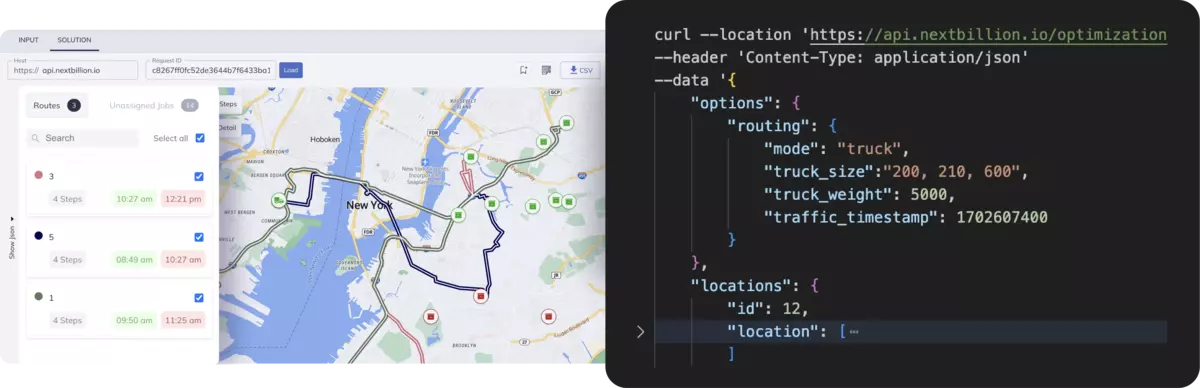

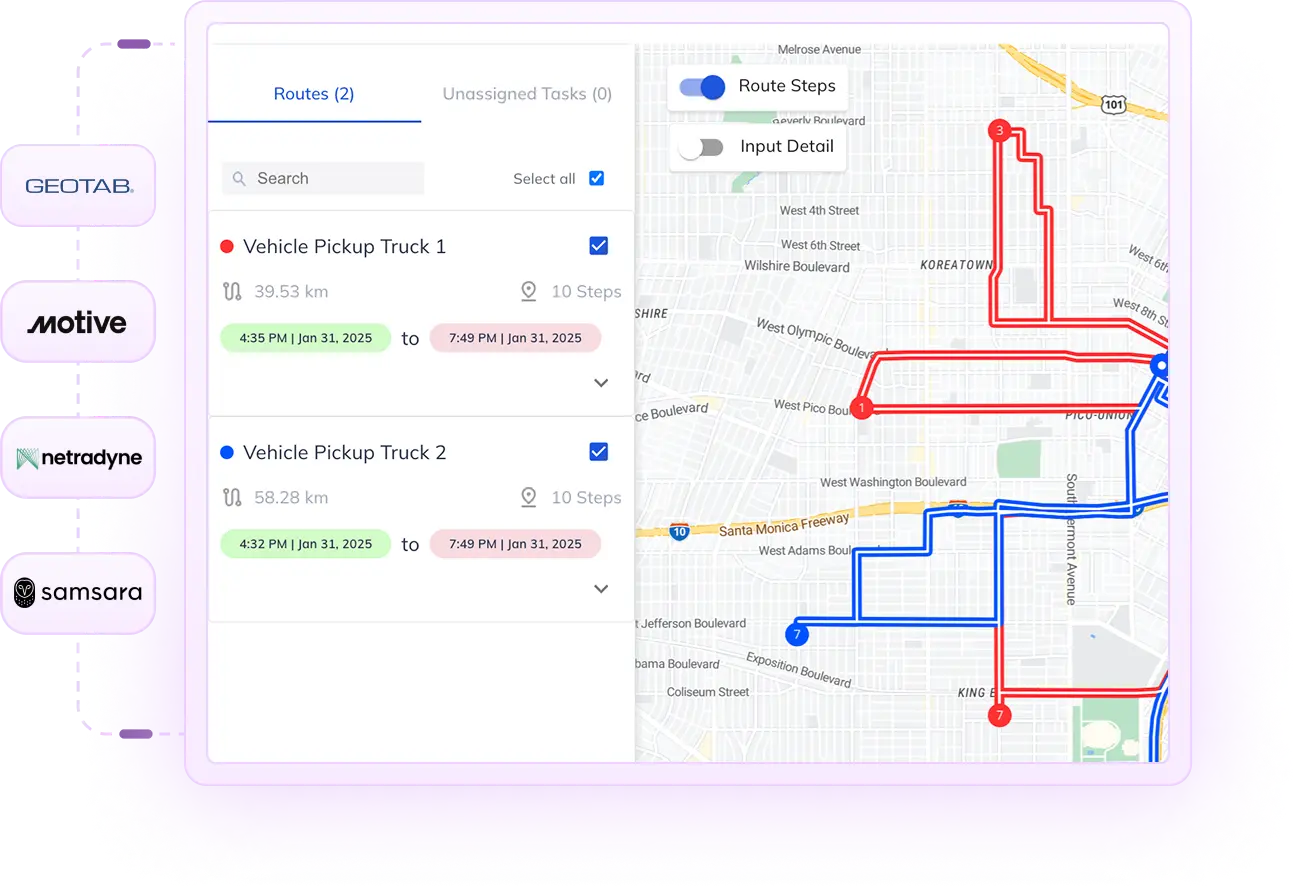

Nextbillion.ai stands out for its ability to work in diverse geographies with messy, real-world data. It allows businesses to feed in custom location formats, integrate local knowledge, and build routing rules that match regional behavior. It does not force a one-size-fits-all logic. It lets the client define how the logic should behave. This makes it ideal for industries such as ride-hailing, last-mile delivery, and large-scale logistics where traditional routing often fails due to informal addressing or dynamic routing conditions.

OptimoRoute is particularly strong in field services and scheduled deliveries. It offers combined route planning and staff scheduling. Its interface is built to support dispatch teams who need visibility into both workload and geographic spread. It works well in environments where service duration is variable and customer preferences matter.

Route4Me serves smaller fleets that need fast setup and immediate efficiency. It balances simplicity with functionality. While it does not handle deeply complex constraints, it is often enough for businesses that are moving from manual to digital routing for the first time.

Google Maps APIs remain common for teams building custom solutions. But it is important to note that they are not routing engines. They offer direction logic, not constraint handling. Any business relying solely on Google Maps for optimization will quickly hit limits unless they build additional intelligence on top of the raw mapping service.

Artificial intelligence is no longer a nice-to-have. It is the mechanism that allows routing engines to adapt, predict, and improve. Traditional systems follow hard-coded logic. They are fast but brittle. The moment something changes, the entire plan breaks and must be rebuilt manually.

AI systems do not just follow rules. They observe patterns. They notice which areas produce the most delays. They remember which customers cancel most often. They adapt estimated service times based on historical driver performance. Over time, they build a model of how your fleet behaves, and they use that model to improve each new route.

Machine learning adds another layer. It allows the system to learn in real time. If a stop is missed due to a roadblock, the system records that and adjusts future route planning in that zone. If fuel usage spikes on a particular route, the system flags that pattern and offers alternatives. These changes may seem small, but they create operational compound interest. The more you use the system, the better it becomes at predicting problems and avoiding them entirely.

This is what makes AI routing different. It does not just find a faster way. It finds a smarter way, then improves it.

Anyone who has ever managed routing on a bad day knows that a clean route plan is not enough. Challenges will show up. The question is not whether the plan will break. The question is how the system reacts when it does. That is what separates basic routing tools from intelligent optimization platforms. It is not the plan. It is the recovery.

Traffic is not a surprise. It is an expectation. Yet many routing systems still treat it as an afterthought. They build a plan once in the morning and freeze it. Then they expect drivers to figure it out when the city turns into a parking lot by 3:00 PM. That does not work anymore. It never really did.

Real-time optimization means the system never stops planning. It listens to live traffic inputs. It watches how long drivers take between stops. It measures current road speed instead of relying on historical averages. And when something changes — whether it is a blocked street, a sudden storm, or an unexpected delay — the system reshapes the route immediately and sends out the update without asking dispatch to intervene.

The best systems do not just respond to traffic. They anticipate it. They recognize patterns. They know which neighborhoods jam up near school zones. They see when events create choke points. And they use that intelligence to make sure the plan accounts for disruption before it starts. That is not a feature. That is survival.

Planning a single route with two or three stops is not difficult. Any GPS app can handle that. The challenge begins when the number of stops increases, the service windows start to overlap, the load types differ, and the drivers have different shift schedules. Suddenly the math explodes. There are millions of combinations. And not all of them are workable.

This is where optimization engines either shine or fall apart. The system must be able to handle constraints. A stop cannot be served before 11:00 AM. A package must stay under a specific temperature. A location cannot be accessed during rush hour. The driver assigned to that route cannot exceed nine hours. And yet, the job must still be completed today. That is what real-world routing looks like.

Good systems use constraint layering to solve these problems. They do not just build the route once and hope. They test combinations. They adjust stop sequences. They look for conflicts and resolve them in real time. And when something changes mid-shift, as it always does in real operations, the engine does not break. It recalculates and keeps the fleet moving.

There is no shortcut to solving multi-stop routing at scale. It takes a system that understands not only logistics, but the operational chaos that comes with it.

Proof does not come from product brochures. It comes from watching how the system holds up in real operations. These are not ideal scenarios. These are actual businesses under pressure, trying to solve problems with routing that has to work.

A major e-commerce company in Southeast Asia had a problem that looked simple on the surface. Too many deliveries were running late. Drivers were reporting burnout. Customers were complaining. On closer inspection, it became clear that the existing routing tool was not designed for cities where addresses are informal, traffic patterns shift hourly, and delivery locations are not always on the map.

After moving to a routing engine that could handle regional quirks, the operation began to stabilize. The system allowed local address formats. It integrated GPS-based tagging. It supported mid-route updates. And it trained on the actual behavior of delivery teams. Within the first three months, failed delivery attempts dropped by more than twenty-five percent. Driver satisfaction increased. Support tickets went down. And the company stopped rebuilding routes manually every afternoon.

A regional food distribution business operating in mixed rural and urban zones had a different problem. Fuel costs were rising. Routes were inefficient. And most trucks returned empty after deliveries. No one was tracking backhauls. Dispatch decisions were made with best guesses. And planners had no way to know where time was being lost.

By implementing an AI-based optimization engine, they were able to create bi-directional routing logic. The system planned outbound trips and searched for pickup opportunities on the way back. It staggered delivery slots to reduce idle time. It balanced vehicle load more evenly across the day. And it made warehouse scheduling more predictable.

Over time, they saved thousands of kilometers per week in wasted mileage. They reduced the number of empty returns. And they improved delivery frequency without adding new vehicles. The system was not just optimizing the route. It was optimizing the entire supply chain rhythm.

The tools we use to plan routes today are already smarter than what most businesses had five years ago. But the road ahead is even more demanding. Optimization will not be optional. It will be embedded in every layer of operations, from vehicle procurement to customer experience design.

Routing engines are becoming more connected to the systems around them. They are no longer operating in isolation. They are reading inventory availability before confirming a delivery slot. They are syncing with CRM systems to understand customer behavior. They are pulling from smart infrastructure to see how traffic signals behave across the week.

Expect deeper integration with IoT devices. Expect vehicles that report their own route performance. Expect optimization models that build around carbon footprint limits, not just fuel economy. Expect routing engines that understand local regulations on emissions, noise, and urban access.

Expect less central control and more edge intelligence. Routing decisions will not always come from headquarters. They will happen on-device, inside the vehicle, reacting to local context that no cloud system can see fast enough.

And above all, expect the customer to see more of the plan. Routing used to be invisible. Now it is part of the brand. Customers want to know when, where, and how their service is arriving. If the system cannot answer that question reliably, it will not survive.

The global route optimization market is projected to exceed ten billion dollars within the next two years. But the number is not the story. The shift in mindset is.

Routing is no longer a technical function. It is a strategic capability. Investors are funding logistics platforms based on how well they can execute under pressure. Customers are choosing providers based on delivery accuracy. And operations teams are designing entire workflows around how adaptive their routing layer can be.

Companies that invest now will not just see better routes. They will see better resilience. And that is what matters most when the entire ecosystem becomes more unpredictable, not less.

Routing has never been simple. But now it is foundational. It is not just about finding a way to move faster. It is about building systems that hold up when nothing goes as planned. AI-powered optimization does not remove the complexity. It makes it manageable.

The companies that will lead in 2025 are the ones that can keep moving when things break. They are not just running better routes. They are building better decisions into the core of their operations. Their teams do not panic when a route fails. Their systems adjust. Their drivers keep going. Their customers stay informed. That is what smart routing looks like. Not a perfect plan. A plan that survives.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.