- BLOG

Solving Split Delivery Challenges in Beverage Distribution

Published: November 26, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Table of Contents

Have you ever noticed how one missed delivery window can ripple through an entire beverage distribution network? Split deliveries usually lead to increased logistics expenses, scheduling confusion, and inconsistent customer experiences. These challenges are further complicated by the fact that distributors must manage varying order quantities, product assortments, and delivery routes. Solving them requires practical planning and intelligent coordination across systems.

In this blog, we will discuss the issue of split deliveries and how beverage distributors can address them to enhance delivery reliability.

Split deliveries are those that happen when a customer order is split into two or more deliveries as a result of inventory, routing or scheduling problems. E.g. a bar or restaurant that orders many drinks, beer, soda, and mixers might not get them all in a single order but would get two or more separate deliveries.

Although in some cases this situation may be inevitable, it usually indicates that there exist defects in the supply chain itself. Common reasons include:

Split deliveries can be a viable workaround, although in the long run they become complicated and expensive, particularly in the case of distributors that deal with high-volume, perishable goods.

The first step to preventing these splits is understanding their causes. Using the causes as a means to identify the root of the problem, be it the inefficiency of the system, inaccurate data, or simply a lack of proper coordination, the businesses will be able to create a more resilient, insight-driven distribution system.

Split deliveries can appear insignificant, but it is easy to forget that they can also affect profitability and brand confidence. Each extra voyage, partial loading, and re-stop is an obstacle to the operation. These inefficiencies can have long-term implications for beverage distributors who already have slight margins.

Unless both the cost of production and its final cost are lowered, the product inevitably becomes more expensive.

Frequent deliveries translate to increased fuel costs, more labour costs, and wear and tear of the vehicles. These accumulate with time-consuming resources that would do well in the growth and innovation.

In cases where the drivers make repeated visits to the same delivery point, the route density is reduced, hence denying productivity. The inefficiency of the consolidation of deliveries also contributes to the massive waste of time, which disrupts the efficiency of the fleet.

Timing is the key in the beverage industry. The bars, restaurants, and retailers rely on the correct, full and timely deliveries to fulfil the expectations of their customers. Split deliveries may lead to frustration and confusion, and may even lead to loss of trust in case they are common.

Split deliveries usually interfere with the activities in the warehouse. In cases where the orders are separated in locations, there is a difficulty in controlling inventory within the right location and thus stock imbalances and errors in forecasting occur.

Reliability is one of the differentiators in the current competitive world. Regular split deliveries may give a brand the appearance of inconsistency or being disorganised, which may force customers to other competitors who can be more reliable.

The multiple sources of split deliveries may be related to various issues, most of which time interrelated. It is necessary to trace the main causes to develop solutions. The most common include:

The distributors are unable to determine the stock levels of locations properly without centralised updated inventory data, and this results in incomplete order fulfilment.

The old or manual planning systems do not consider live variables such as traffic, weather conditions and load optimisation. This creates poor paths and tours to the same location.

Beverage distribution is usually characterised by several storage locations. In case there is a lack of coordination between these warehouses, split shipments are bound to occur.

A miscalculated forecast of the volume of orders or the demand for the products will lead to a shortage of stocks, and then the distributors will be forced to supply the orders in phases.

Sales, logistics, and warehouse management systems are not integrated; hence, there are delays in communication, split orders and late deliveries.

All these are aspects that highlight the same theme, which is the absence of visibility and control. There are numerous moving parts of beverage logistics, and the lack of unified data and intelligent route optimisation will result in the appearance of operational inefficiencies.

The following aspects illustrate how data insights can change distribution performance:

Advanced analytics and machine learning models can be used to determine consumption patterns and predict order volumes in the future. These predictions ensure that appropriate stock quantities are held in every depot, minimizing shortages and fragmented deliveries. Demand forecasting enables distributors to plan production and delivery cycles in tandem.

The stock information of all warehouses is centralized in inventory dashboards. Teams can instantly see available quantities, pending orders, and anticipated deliveries. Such visibility helps avoid duplication of allocations and order failures, enhancing accuracy and response time.

Live parameters considered by AI-based routing engines include traffic density, weather conditions, vehicle capacity, and delivery urgency. They develop the best paths that reduce unnecessary mileage while balancing loads across fleets. This not only minimizes split deliveries but also improves on-time performance and fuel efficiency.

Interactive dashboards are used to monitor key performance indicators, including fulfillment rate, delivery timeliness, and vehicle utilization. This information shows how repetitive problems are and allows decision-makers to correct inefficiencies before they affect service quality. Performance monitoring establishes a continuous improvement cycle over time.

Sales, warehouse, and logistics systems are integrated into one platform, which enhances coordinated communication. Orders flow smoothly between sales input and warehouse output, minimizing data silos and improving order accuracy. A single technology stack ensures that all stakeholders work with the same information at any given time.

Transforming fragmented data into actionable insights enables distributors to redesign their operations from reactive to predictive. This shift improves cost efficiency, reduces delivery fragmentation, and strengthens brand credibility in competitive beverage markets.

The most effective way to address split deliveries is to prevent them before they occur. Prevention not only minimises costs and customer complaints but also strengthens the foundation of efficient beverage logistics. The key lies in proactive planning, smart technology adoption, and continuous alignment between teams.

Fragmented or out-of-date inventory information has been viewed as one of the most prevalent reasons behind split deliveries. In a situation where there are several warehouses and depots with no real-time visibility, it is almost impossible to make sure that the orders are fulfilled completely.

The use of a centralised inventory management system, which replaces the stock level in real time, would assist the distributors in knowing the location and type of stock. ERP, WMS, and TMS systems related to the same dashboard provide the distributor with an opportunity to reduce the number of human errors and dispatches made due to the inventory mismatch.

Successful logistics is based on precise forecasting. The consumption pattern of beverages is seasonal, promotional and local preferences. Systems of predictive analytics can be used to forecast demand peaks, which can be used by the warehouses to pre-order and avoid the demand peaks at the last moment, which may result in split orders.

AI models can be fed with historical sales data, consumer behaviour, or external conditions, including weather or events, to forecast the trend. This allows resources to be better distributed and will guarantee stock consistency in different locations.

The problem of misalignment of sales engagements and operational capabilities frequently results in partial deliveries. By building a cooperative environment where both teams are made visible into the existing stock, orders, delivery schedules, and customer expectations, the promises of the orders will be realistic.

This gap can be filled through regular communication meetings, joint dashboards, and coordinated communication tools, so that the pledges made to clients are synchronised with what the logistics team can perform.

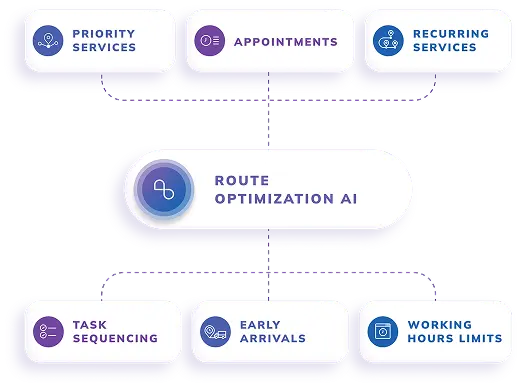

Intelligent route planning systems powered by AI and machine learning help distributors design efficient routes based on delivery windows, vehicle capacity, and priority stops. These systems can dynamically adjust routes if delays or disruptions occur, ensuring that all orders reach their destinations in a single trip whenever possible.

By combining load optimisation (maximising space utilisation) with route optimisation (minimising travel time), distributors can significantly reduce the risk of split deliveries caused by partial truckloads or poorly sequenced drop-offs.

Sometimes, split deliveries occur not due to logistics but due to quality rejections. Establishing a data-driven quality control process ensures that products meet standards before leaving the warehouse, reducing the need for redeliveries caused by returns or replacements.

Proactive strategies like these turn potential delivery challenges into opportunities for improved efficiency, customer trust, and long-term growth.

The beverage industry is one that has undergone a technological change in the last few years. With AI-controlled logistics software, real-time visibility software, and more, current solutions are making even the most complicated delivery networks easier.

Collected data of order volume, location of delivery, type of vehicle, availability of drivers, and pattern of traffic are all examined by AI-based systems to generate the most effective delivery paths. This minimises redundancies, consolidates shipments and minimises the possibilities of split deliveries.

In addition to this, the systems are able to adjust in real time. Indicatively, in case a truck is delayed or the customer has rescheduled, the AI will automatically reroute other deliveries to ensure efficiency.

There must be transparency in beverage logistics. The new GPS-based tracking applications enable the distributor, retailer, and customers to track shipments in real time. Such devices will provide one with real-time information about the location of a car, what it is loaded with, and when to expect its arrival.

This visibility will make sure that any problem that may arise, such as delays, half shipments or wrong deliveries, can be detected and fixed before it can interfere with customer satisfaction.

One of the largest logistics bottlenecks is disconnected systems. Beverage distributors can create an integrated system of data by incorporating Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP), and Customer Relationship Management (CRM) systems.

With this integration, inventory, order management, as well as delivery teams can work in harmony, and this reduces by huge proportions the number of mistakes that cause split deliveries.

Automation is used to remove the errors of manual order consolidation. The present-day distribution software can identify overlapping addresses of delivery, types of products and order schedules to consolidate shipments automatically.

This is to make sure that the customers get their entire order once, and this enhances satisfaction at a lower cost of operation.

Real-time analytics dashboards help logistics managers monitor delivery performance and uncover inefficiencies. By visualising data such as “delivery success rate” or “split delivery percentage,” teams can identify recurring issues and refine strategies accordingly.

In short, modern technology transforms beverage distribution from a reactive process into a proactive, data-informed system that prevents inefficiencies before they occur.

It all lies in smooth execution that all the strategies are accurately implemented and yields desirable outcomes. A smooth flow of delivery relies on the three fundamental aspects: coordination, consistency, and communication.

Time sensitivity of the products is essential because beverage distributors have fleet coordination. Scheduling software assists in the allocation of vehicles depending on capacity, efficiency of routes and delivery deadlines.

Coordinated fleet management will make sure that all trucks are loaded, all the routes are optimised, and get the full combination of their order.

The final mile is usually the most difficult stage of the distribution chain. This is prone to split deliveries in case of unpredictability of the routes and demands of the customers, which are customer-specific.

Using the last-mile optimisation solutions, beverage firms will have the opportunity to manage the deliveries dynamically on the fly and make sure that even unforeseen events, like road closures or inaccurate addresses, do not interfere with the deliveries.

Open communication between the customers creates trust and lowers the friction in delivery. Notifications, delivery proof (POD) and feedback systems are automated, which enables customers to remain updated, verify their order, and complain in real-time.

This not only makes this enjoyable but also ensures that discrepancies that lead to split deliveries are dealt with beforehand.

Distributors will be able to make informed decisions on the spot using live information on IoT devices, fleet tracking systems, and order management software. As an illustration, in case a delay is observed, dispatchers have an opportunity to route other traffic or notify the customer, avoiding overlaps in delivery or visiting the same house twice.

A seamless implementation model will turn the logistics into a network of dynamic and adapting ecology where each decision leads to better consistency of the deliveries.

It is required to constantly improve efficiency in delivery. When a distribution system exists, it is continuously optimised so that it will be relevant and efficient to the changing market conditions.

Intelligence, connectivity, and customer centricity are the factors that determine the future of beverage logistics. With digital transformation redesigning the supply chain, distributors are shifting towards predictive and data-driven ecosystems instead of reactive operations. The future of beverage distribution will be smarter, more integrated, and environmentally conscious than ever.

Artificial Intelligence will continue transforming predictive logistics by allowing distributors to predict disruptions in advance. The variables analyzed by machine learning models will include order frequency, fleet conditions, route congestion, and customer demand trends to identify bottlenecks. Predictive algorithms will not only approximate order volumes but will also plan proactive vehicle maintenance and allocate resources optimally.

These advancements will help distributors develop self-learning systems that dynamically balance load capacity, adjust routes in real time, and improve service reliability across complex distribution networks.

Sustainability is rapidly emerging as a performance indicator in beverage logistics. Future operations will focus on reducing emissions through route optimization, energy-efficient warehousing, and the adoption of electric or hybrid delivery fleets.

AI-based carbon tracking applications will measure fuel consumption, monitor carbon intensity, and suggest more environmentally friendly routes. Companies that incorporate environmental impact analytics into their delivery services will not only meet new regulatory requirements but also enhance brand recognition and appeal to environmentally conscious customers.

Digital twins are virtual copies of logistics ecosystems and will transform operational planning and risk management. These simulation environments will enable managers to model real-world variables such as vehicle performance, warehouse throughput, and traffic patterns before making adjustments.

By simulating different scenarios within a virtual environment, distributors can experiment with route changes, loading configurations, or demand variations without disrupting real-time operations. This digital foresight will improve decision quality, reduce operational risks, and strengthen system resilience.

Beverage companies are adopting hyperlocal distribution models to meet rising customer demands for speed and flexibility. Micro-warehousing located close to major consumption zones will reduce last-mile delivery time and minimize split shipments.

AI-driven inventory replenishment and dispatch scheduling will automate resource allocation, helping reduce turnaround times while maintaining product freshness. These hyperlocal models not only cut transit distances but also enhance customer satisfaction by enabling same-day or just-in-time delivery.

The future of beverage logistics lies in seamless data flow among all stakeholders, including suppliers, distributors, and retailers. The integration of ERP, CRM, WMS, and TMS systems into a single digital framework will synchronize visibility across all supply chain levels.

This unified infrastructure will support collaborative forecasting, shared inventory intelligence, and coordinated dispatch planning. The result will be a responsive ecosystem capable of adapting instantly to shifts in demand, supply shortages, or transport disruptions.

Beverage distribution is evolving into a more responsive, intelligent, and sustainable model. Companies that invest early in AI-based analytics, automation, and integrated technologies will gain a competitive advantage. The future belongs to distributors who view digital transformation not as a trend but as the foundation of operational excellence and customer loyalty.

Split deliveries are not a mere inconvenience to logistical operations, they are a symptom of inefficiencies that are transmitted to the whole distribution system. In the case of beverage companies, it is not only about cost savings but a better brand reliability, customer satisfaction and better long-term profitability.

If your beverage distribution network is having problems with split shipments, delivery delays, or inefficient routes, NextBillion.ai provides the intelligent, data-driven solutions you need to take back control and increase productivity. Our platform helps you optimise every mile of your delivery journey, from real-time visibility tools and advanced route optimisation to AI-powered analytics that anticipate and stop delivery problems before they happen.

To streamline processes, increase consumer satisfaction, and create a beverage distribution system that is ready for the future and consistently delivers, collaborate with NextBillion.ai now – Contact us today!

Distributors may better manage inventory, reduce split deliveries, and guarantee on-time, full-order delivery with the help of AI-powered logistics solutions, intelligent route optimisation platforms, and real-time visibility systems.

Important tactics for big beverage networks to avoid split deliveries include keeping up-to-date inventory records and coordinating transportation. They also include tracking warehouse activities, anticipating order quantities with predictive analytics, and putting automated dispatch systems in place to effectively coordinate deliveries.

NextBillion.ai offers advanced mapping and routing systems that enhance fleet coordination, optimise delivery routes, and enable end-to-end visibility. Ensuring on-time, comprehensive, and economical deliveries lowers split shipments and raises customer satisfaction.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.