- BLOG

How Does Direction API Power Control Tower Operations in Global Logistics Hubs?

Published: October 13, 2025

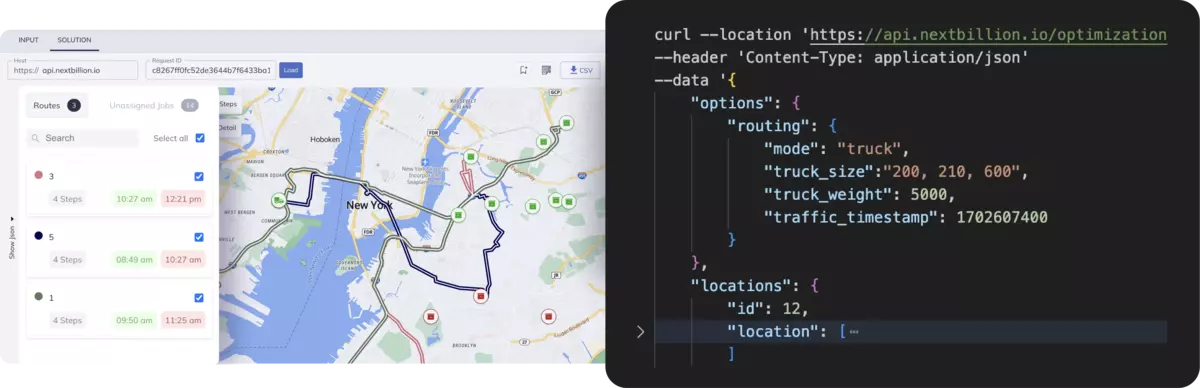

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

Ever wondered why some supply chains glide effortlessly across borders while others constantly hit delays? The difference often comes down to how intelligently routes are planned and adjusted in real time. A modern logistics control tower is the brain of global logistics hubs, and its true strength emerges when powered by tools like a direction API and route optimization API. These integrations transform routing from a static plan into a dynamic capability that cuts costs, improves ETAs, and boosts sustainability.

Keep reading to see how direction APIs are reshaping control tower operations and setting a new standard for global logistics.

Complexity is not an exception in global logistics. Orders travel through oceans, clogged ports, and into massive distribution centres, where any minor delay will run through the supply chain. Enterprises can overcome this complexity by using a logistics control tower, a centralized system that provides real-time visibility and coordination of all nodes of the supply chain. Imagine it as a mission control of freight: tracking flows, predicting disruptions, and coordinating responses on high scales.

The supply chain control tower enables the combination of data provided by carriers, warehouses, ERP systems, and IoT devices in a single view. But it is not only visibility that is the beginning. It only has a true value in converting data into action, i.e., re-assigning loads, re-allocating assets, or producing proactive route corrections.

The following are some of the major capabilities of a modern control tower:

With a combination of sophisticated applications such as a Direction API, a control tower transforms into being active instead of passive. It is not just able to mark where a delay has happened, but can compute alternative paths, update ETAs live, and maintain world logistics centres in optimum performance.

Operating an international logistics center is to handle an infinite number of moving parts, literally. All delays are downstream, since the container vessels that dock in the ports and moving trucks in the congested roads all affect each other. A Logistics Control Tower serves as the brain center, where coordinated data streams are used to keep the operations on track.

However, when used together with such APIs as a Route Optimization API or Direction API, its real worth becomes apparent, introducing the element of intelligence and automation to everyday decision-making.

The following are the ways in which the control towers enhance the operations of logistics:

With the integration of the Direction API into control towers, a business gets orchestration rather than visibility. This not only avoids bottlenecks, but it also brings quantifiable cost savings, reliability, and customer satisfaction; three of the measures that determine competitiveness in global logistics.

Each logistics control tower is anchored by a single basic role, which is the route planning. It is essential to visibility, it is not very useful to know the location of a truck at a given moment without being able to determine where it should be going.

Planning of the routes makes control towers not just spectators but coordinators. This can be made more accurate and even scalable over complex, global networks when driven by a direction API or route optimization API.

This is the way the supply chain performance is influenced by advanced route planning:

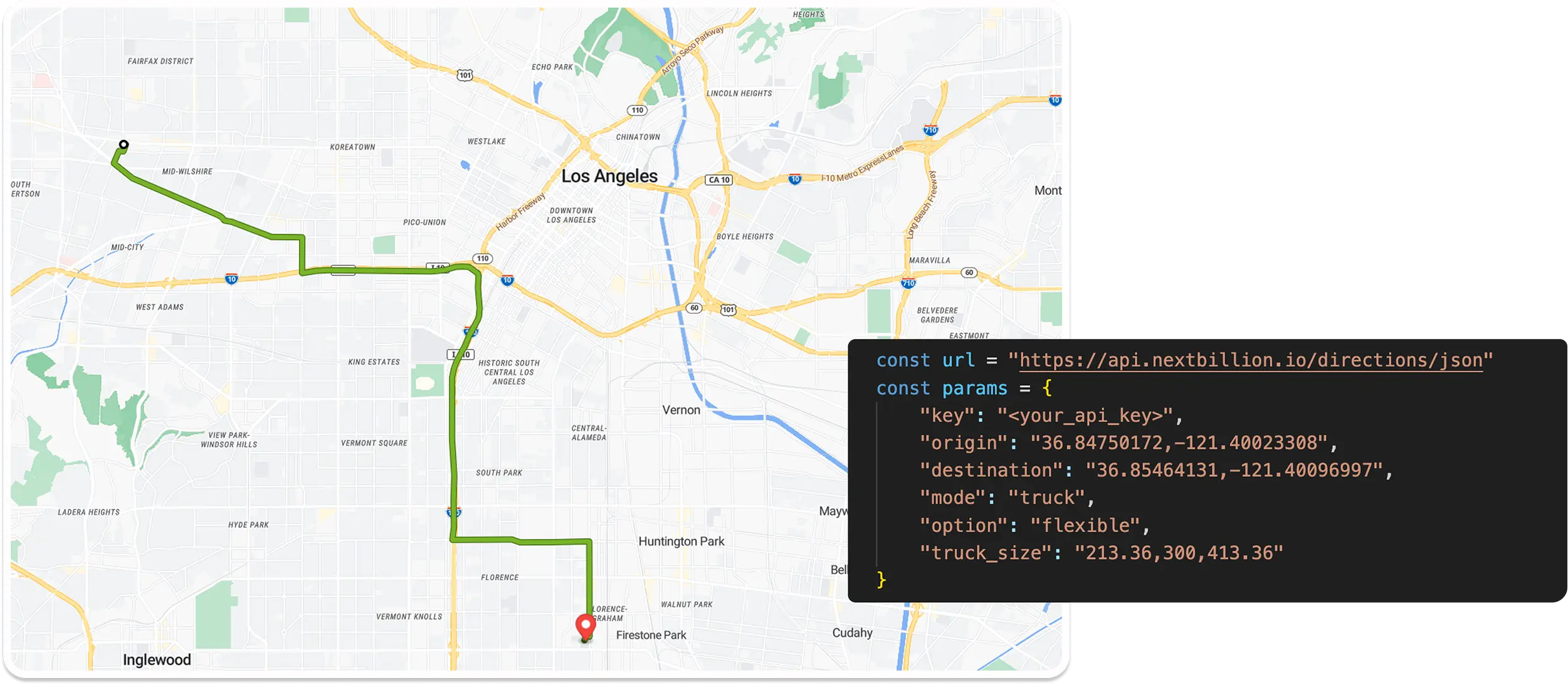

Visibility can provide information on where the shipments are; routing intelligence can provide information on where they should be going. Control towers take a direction API, GPS signals, real-time traffic feeds, and road network intelligence to generate optimal routes. These factors not only save time but also save costs. Rather than fixed routes, operators receive dynamic and data-based suggestions.

Disruptions in logistics center such as traffic jams, roadblocks, strikes, or even weather-related events are unavoidable. Static routing is not able to change mid-journey. The control tower is able to recalculate routes within a few seconds with a direction API and send updated turn-by-turn directions to the drivers. This reduces wastage and keeps shipments on schedule even in volatile conditions.

The supply chains of most global operations are multi-modal, involving road, rail, sea, and air. Planning the route does not just concern the use of trucks, it is about ensuring smooth intermodal transfers. APIs assist control towers in modeling time windows, customs requirements, and port congestion to ensure continuity throughout the entire logistics chain.

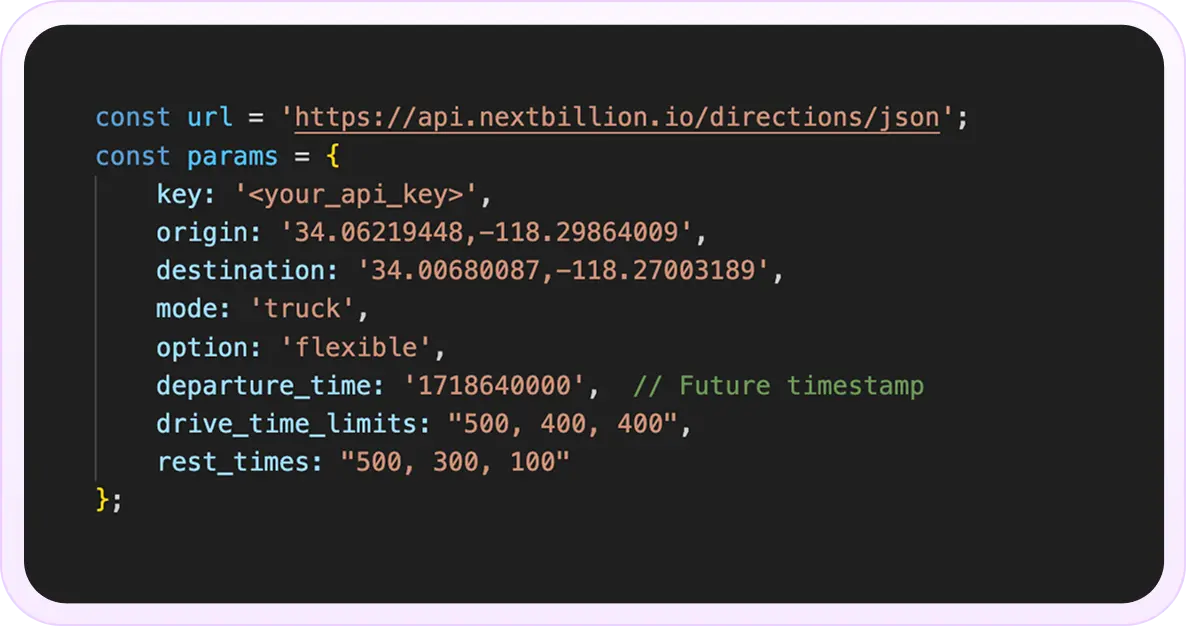

Current customers, whether retailers, manufacturers, or end-consumers, desire guaranteed delivery windows. APIs support ETA accuracy by factoring in live road speeds, toll stops, driver hours of service, and historical traffic trends. This real-time accuracy decreases missed SLAs and enhances customer confidence.

Using modern route planning is not only about speed, but also about balance. Before suggesting a route, a route optimization API can take into account fuel costs, tolls, driver shifts, and carbon impact. The result is not only faster deliveries, but smarter ones, saving costs and achieving sustainability objectives.

Concisely, route planning is not a background process anymore, it is the essence of the intelligence layer of a logistics control tower. The integration of a direction API within workflows enables global logistics hubs to respond almost instantly, scale without issues, and approach their work with an accuracy that manual planning cannot achieve.

Even though a logistics control tower provides visibility and coordination, its intrinsic routing functions tend to be less than adequate. Control towers alone are able to track shipments and call exceptions, but without the addition of a direction API or route optimization API, they will not be effective at dynamic decision-making. Here are the key gaps:

A majority of control towers are capable of making a route plan at the beginning of a trip and are rarely able to change it during the middle of the journey. A port going dead, a highway closed, or city traffic brought to a crawl due to congestion all lead to static planning in place of responsive rearrangement.

The database of a control tower is typically not as granular and constantly updated with map intelligence as an API like a direction API. Important information such as bridge heights, truck limitations, turn restrictions, or live detour information is not available, resulting in incorrect or unrealistic routing decisions.

The nature of logistics operations is fluid. Without integration, control towers cannot recalculate routes in real time to optimize mileage, balance driver hours of service, or fulfill last-minute customer needs.

Unproductive routing compounds costs. The greater the mileage, the greater the fuel usage, the increased maintenance, and the overtime. With large fleets of thousands of trips, these inefficiencies represent millions of overheads every year.

Late ETAs and unreliable delivery times are damaging to trust. In the absence of real-time recalculations, customers are left in uncertainty, and service teams are in a difficult position to give accurate updates.

Companies under ESG pressure must reduce emissions. Without dynamic routing, trucks consume unnecessary fuel, accumulate empty miles, and expand their carbon footprint.

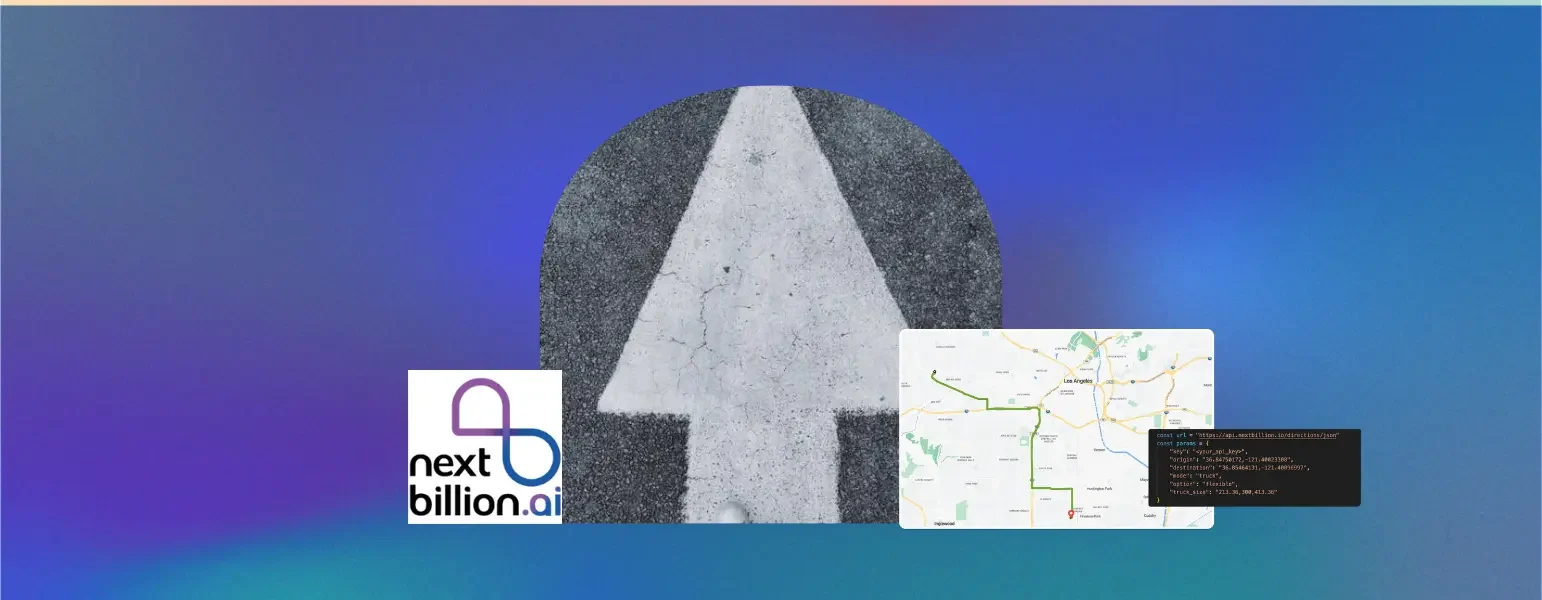

A direction API is a service of geospatial intelligence that allows a logistics control tower to convert fixed shipment plans into real-time and adaptive routing plans. In contrast to manual routing or pre-defined schedules, a direction API integrates live data streams such as traffic, road restrictions, weather, and vehicle constraints to provide the most efficient solution to numerous points. This makes visibility actionable intelligence when it is incorporated into a logistics control tower.

Direction API levels up control tower route planning in the following ways:

Rather than using predetermined route lists, a direction API creates routes using real-time requests such as congestion, road closures, or reports of incidents. Take the instance of a highway adjacent to a distribution hub being blocked, here the control tower is competent to divert truck routes through secondary roads to keep delivery schedules intact.

The APIs consider speed profiles, historical traffic patterns, length of stops, and hours of service by drivers to obtain very precise ETAs. The control towers are then able to provide accurate delivery windows to both customers and partners, minimizing disputes related to delays.

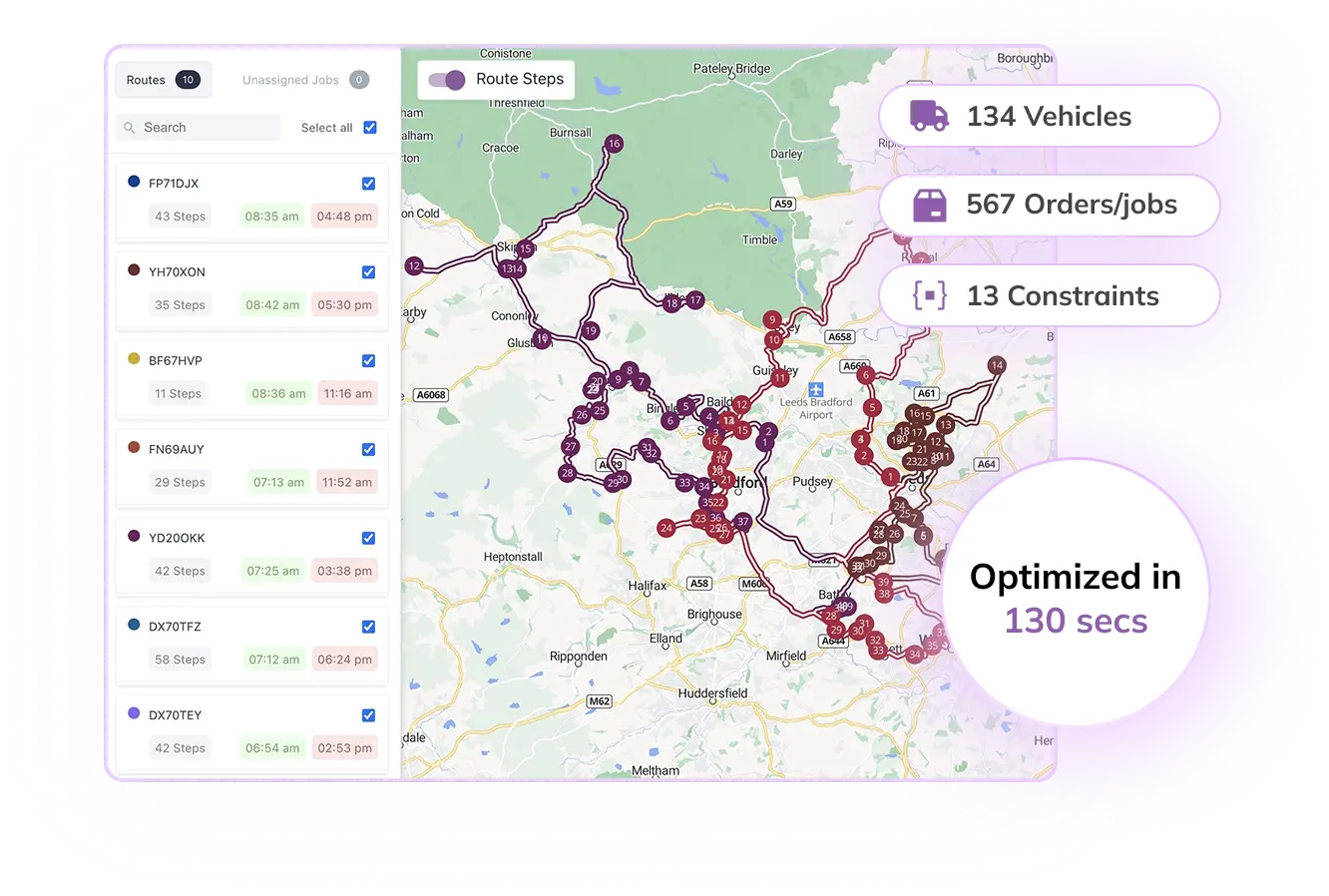

Contrary to basic point-to-point routing models, a route optimization API may order deliveries across multiple stops, balancing limitations such as delivery time windows, load capacities, or cold-chain integrity. This minimizes unproductive mileage and optimizes fleet performance.

Fleet constraints are also integrated into APIs, including truck height, weight, axle load, or hazardous material restrictions. This ensures that a heavy trailer is not dispatched across a bridge with weight restrictions or into areas with chemical transportation restrictions, enhancing compliance and safety.

The control tower does not just react to API integration, it anticipates. For example, if weather forecasts predict a serious storm along a truck route, the system can actively recommend an alternative route before the driver is affected by the disruption.

The cost of transporting cargo across borders in international global logistics hubs includes fluctuating freight rates, customs fees, and regulatory peculiarities. APIs enhance the regional intelligence of control towers so that carriers can deal with these challenges while ensuring compliance and efficiency.

A direction API is not merely creating the shortest line between Point A and Point B. In fact, it is a complex decision-making process that can combine geospatial intelligence, logistics restrictions, and real-time data streams to assist in logistics control tower operations. When implemented within global logistics hubs, it transforms into the foundation of active planning, disruption management, and performance benchmarking.

Following are the best technical advancements that make a direction API critical in current logistics:

Control towers are capable of building predictive models based on direction API data that can be tested with a variety of routing options in advance of disruptions. For example: What happens when a large port goes out of commission with only 24 hours’ notice? What would happen in case of high congestion on a highway? This feature enables planners to validate contingency paths, simulate financial impact, and enhance resilience measures.

Direction APIs, unlike their counterpart, static routing, optimize across multiple stops while considering constraints such as delivery time windows, vehicle capacities, cold-chain compliance, or hazardous material restrictions. This ensures that the route optimization API does not just minimize distance, but balances the complexity of operations.

By comparing real GPS paths with optimized ones, control towers are able to gauge compliance, quantify inefficiencies, and benchmark carrier performance. This bridges the gap between planning and execution, feeding continuous improvement programs.

Direction APIs in route calculations incorporate regulatory logic. They consider restrictions such as bridge heights, axle-load limits, truck-restricted zones, and Hours of Service (HOS) regulations. This minimizes the chances of penalties, accidents, and legal breaches.

In international logistics, the shortest path is not necessarily the fastest or most compliant one. APIs introduce local information such as toll fees, customs waiting times, ferries, and seasonal road closures. This context ensures that routes are efficient as well as operationally viable across different jurisdictions.

With more precise routing information, downstream logistics operations become sharper. Dock schedules in warehouses can be planned with more accuracy, driver rest stops can be optimized, and fleet dispatching can be coordinated with yard and terminal activities.

Direction APIs produce route-level emissions data. This allows logistics control towers to provide accurate carbon impact metrics to ESG dashboards, transforming sustainability from a broad corporate commitment into a tangible and quantifiable result.

The combination of features of a direction API is what renders transformative value, although its technical basis is established by the features of a logistics control tower. The control tower becomes more of a command center rather than a passive dashboard, and is able to make dynamic decisions at scale.

The main business and operational advantages of this integration include:

In the world of global logistics, there is seldom a time when everything is on schedule. Weather, port congestion, and traffic spikes in cities are all variables. With an embedded direction API, a control tower can recalculate routes immediately, send revised instructions to drivers, and reschedule deliveries while keeping them on track regardless of unforeseen circumstances. This flexibility ensures assets are not left idle for long, and cascading delays in supply chains are avoided.

Accurate ETAs are the co-foundations of customer satisfaction. APIs consider aspects such as driver rest periods, live congestion, and vehicle limitations to generate precise, constantly up-to-date ETAs. This enables control towers to deliver reliable updates, minimize service-level violations, and earn customer and partner confidence in global logistics hubs.

Every mile counts in fleet operations. Optimized routing minimizes unnecessary mileage, reduces fuel burn, and lowers maintenance costs. For fleets managing thousands of shipments per day, a 5–10 percent decrease in distance may equate to millions of dollars in savings annually. APIs also improve utilization of driver time and fleet resources, ensuring they are used in the most efficient way possible.

Compliance with regulations is a complicated matter, particularly for cross-border and heavy freight. Direction APIs take into consideration bridge height restrictions, axle loads, and hazardous material routing regulations automatically. This ensures shipments move along legally approved routes, avoiding fines and reducing the risks of accidents caused by poor routing decisions.

Scenario simulation and what-if analysis allow control towers to anticipate disruptions before they occur. For example, planners can simulate how closing a seaport affects delivery schedules and reassign alternative carriers or modes. This predictability enables supply chain resiliency and supports strategic future planning.

Large companies operate fleets across multiple regions. Direction APIs enable multi-stop optimization, cross-border routing intelligence, and region-specific compliance, all while calculating thousands of routes in parallel. This scalability allows control towers to efficiently manage both local urban deliveries and global multimodal flows.

Optimization of routing not only reduces costs but also directly lowers a company’s carbon footprint. APIs help control towers align with corporate ESG objectives by reducing empty miles, cutting idling, and promoting fuel-efficient routes. Sustainability reports can incorporate route-level emissions data, making carbon savings measurable and auditable.

Each optimized route generates valuable information. By analyzing deviations, delays, and performance metrics, a control tower can identify systemic inefficiencies, benchmark carriers, and refine routing strategies over time. This creates a feedback loop of continuous improvement, ensuring operations become smarter and more efficient with every mile.

Most direction APIs offer simple routing functionality, but the direction API and route optimization API by NextBillion.ai are tailored to the challenges of logistics, fleet management, and scale. They introduce sophisticated customization, extensive scalability, and compliance-ready intelligence that make them specifically suited to drive a logistics control tower in any global supply chain.

The difference between a traditional logistics control tower and one enhanced with a direction API or route optimization API can be seen clearly below:

Factor | Without Direction API | With Direction API |

Routing Method | Static, pre-defined routes. | Dynamic, real-time recalculations based on live traffic and disruptions. |

ETA Accuracy | Often unreliable, prone to delays. | Highly accurate, factoring in traffic, driver hours, and historical trends. |

Disruption Handling | Reactive; delays addressed only after they occur. | Proactive; routes recalculated instantly to avoid bottlenecks. |

Operational Costs | Higher fuel, labor, and maintenance costs. | Lower costs through optimized mileage and efficient fleet utilization. |

Compliance & Safety | Risk of violating road, weight, or hazardous material rules. | Routes adapted automatically for regulations and vehicle-specific constraints. |

Customer Experience | Missed SLAs, late deliveries, and low trust. | Reliable ETAs, higher satisfaction, and stronger customer retention. |

Sustainability | Higher carbon emissions due to inefficiencies. | Reduced emissions through smarter routing and fewer empty miles. |

Scalability | Limited ability to handle large or multi-modal operations. | Efficiently manages multi-stop, cross-border, and fleet-wide routing at scale. |

Visibility is not sufficient in the complex global supply chains of today. A logistics control tower is enhanced in particular by an API such as a direction API or route optimization API, which converts it from an inactive monitoring engine into an active decision-making engine. Enterprises become operationally agile, lower costs, enhance customer satisfaction, and maintain a sustainability focus by incorporating real-time routing intelligence.

For global logistics hubs that must manage multimodal flows, cross-border complexities, and rising ESG pressures, this integration is no longer a choice but a competitive imperative. Applications such as the direction API and route optimization API by NextBillion.ai provide the capability to scale, comply with requirements, and customize workflows to drive efficiency at both fleet and network levels.

Industry-leading companies that incorporate routing intelligence in their control towers are not only streamlining deliveries but also future-proofing their supply chains.

A direction API is a service that computes the most efficient route between two or more locations, considering current traffic, constraints, and regulations. This data forms the foundation of a route optimization API or engine, which can then be used to perform complex logistics tasks such as multi-stop sequencing, fleet-wide optimization, and scenario simulations. In practice, the two often work hand in hand: the API provides raw routing intelligence, while the optimization engine coordinates execution at scale.

The accuracy depends on the quality of data inputs. State-of-the-art APIs, such as NextBillion, integrate live traffic feeds, historical traffic trends, road restrictions, and driver hours-of-service data. This results in highly reliable ETAs, often accurate to within a few minutes of actual arrival, even for long-haul or multi-stop routes.

Yes, but indirectly. The calculation of travel times between points is done within the direction API itself. However, planners can incorporate warehouse-specific constraints such as docking schedules, yard congestion, or facility handling times when integrated into a logistics control tower. This combination ensures that ETAs are not only dependent on road conditions but also reflect the operational realities of the facility.

The initial expenses involve API licensing, integration, and training. However, the benefits quickly outweigh the costs, as advantages multiply across fleet operations:

For large fleets, even a 2–5% increase in efficiency can translate into savings worth millions annually, far exceeding the initial investment in a direction API and its integration within a logistics control tower.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.