- BLOG

The Role of AI in Data Center Construction Logistics

Published: November 25, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

AI is quietly becoming the “hidden general contractor” behind modern data center builds – orchestrating people, materials, and machines so that thousand-ton projects move with millimeter-level precision.

Below is a detailed article you can use almost as-is (blog/whitepaper), with a natural transition at the end to NextBillion.ai and how its platform fits this space.

AI data centers are exploding in scale and complexity. Hyperscalers and colocation providers are racing to deliver campuses measured in gigawatts and millions of square feet, often under brutal timelines and constrained labor, power, and supply chains.

Unlike conventional projects, data center construction logistics must deal with:

This creates an enormous orchestration problem: dozens of trades, thousands of deliveries, time-windowed access, oversize/overweight loads, and near-zero tolerance for rework.

That is exactly where AI-driven logistics comes in.

AI in this context is not just robots on site; it’s a stack of intelligence across planning, routing, scheduling, and real-time coordination.

Before a single truck rolls, project teams must understand:

AI-powered routing and geospatial tools can:

This is particularly important for remote or rural data center sites, which often combine incomplete map data with high traffic from construction fleets.

Modern mission-critical projects already rely on sophisticated scheduling tools. AI enhances this by:

On the logistics side, AI connects scheduled data to the real world by synchronizing when work is planned and when material must appear at the gate.

The physical backbone of construction logistics is the trucking and delivery network:

AI-driven route optimization engines can:

Space inside a data center construction site is incredibly constrained. Poorly timed deliveries cause:

AI + geospatial tools help by:

This closed loop reduces both idle time and chaos at the site entrance.

Data center builds require thousands of workers across multiple shifts. AI can:

These insights support safer logistics plans and better use of shuttle fleets and parking.

Stakeholders increasingly expect:

AI systems, powered by rich logistics data, can:

For AI data center builds, where sustainability scrutiny is high, this is quickly becoming a must-have.

A practical architecture usually has these layers:

Next, let’s look at how a specialized platform like NextBillion.ai maps into this architecture.

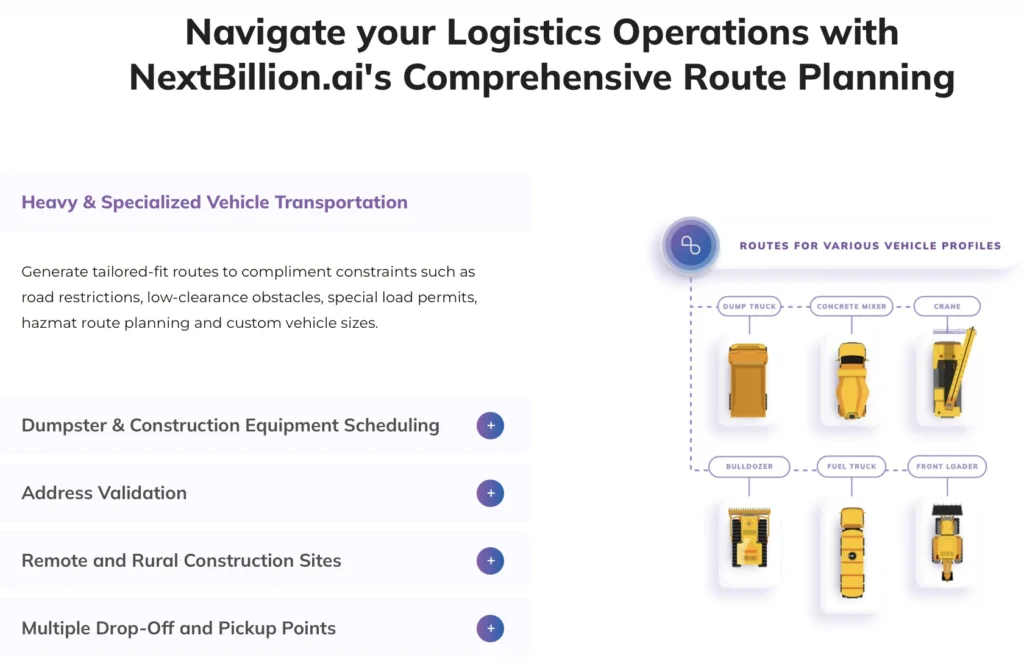

NextBillion.ai is a route planning and optimization platform focused on complex, constraint-heavy logistics. Although it’s widely used for last-mile, rural logistics, and construction solutions, many of its capabilities align perfectly with data center construction projects.

For data center logistics, you often need:

NextBillion.ai’s Route Optimization API allows you to model more than 50 constraints, covering:

For data center construction, this means you can generate dispatch-ready routes that already respect your crane schedules, gate slots, and staging areas, reducing the need for manual tweaking by dispatchers.

Construction logistics rarely follow textbook patterns: weather, laydown constraints, and local roads make every project unique.

NextBillion.ai’s AI Route Optimization is designed to learn from your historical fleet performance, not just static rules:

This is especially valuable on large data center campuses where “the last 10 km” around the site are often the most unpredictable.

NextBillion.ai has a dedicated construction solutions focus that addresses:

For data centers, where sites are often greenfield, this means you can:

To execute AI-optimized plans, you need real-time visibility.

NextBillion.ai provides:

For APIs, please refer here.

For APIs, please refer here.

For data center construction, this supports:

Many data center projects involve strict security and data residency requirements. NextBillion.ai supports:

For hyperscale or government data centers where logistics data is sensitive, this is a critical differentiator compared with public-only SaaS routing tools.

NextBillion.ai exposes functionality via APIs, making it straightforward to integrate with:

In practice, this means you can:

AI in data center construction logistics is not a futuristic add-on—it’s becoming the only practical way to orchestrate:

By combining AI-driven scheduling, route optimization, geospatial intelligence, and real-time tracking, project teams can:

If you’re exploring how to operationalize this on real projects, it’s worth looking at NextBillion.ai as a core building block:

From design through commissioning, AI-powered logistics can be the difference between a data center project that constantly fights fires and one that quietly delivers capacity exactly when the market needs it. Exploring NextBillion.ai’s platform is a practical next step toward that future.

In summary, AI is reshaping the way data center construction projects are planned, executed, and managed and turning complex, constraint-heavy logistics into predictable and efficient workflows. As demands for larger, faster, and more secure data center builds continue to grow, adopting AI-driven routing, scheduling, and real-time visibility will become essential rather than optional. This is precisely where NextBillion.ai stands out: its advanced route optimization engine, customizable mapping capabilities, geofencing tools, and real-time tracking APIs give construction teams the intelligence and control they need to keep every delivery, heavy-haul movement, and on-site operation running smoothly. For organizations looking to modernize their construction logistics with scalable, high-performance AI, NextBillion.ai offers a powerful, future-ready solution built to meet the demands of mission-critical data center development.

👉 So, without any delay book a demo with NextBillion.ai today and see how NextBillion.ai can help optimize the role of AI in Data Center Construction Logistics.

Prabhavathi is a technical writer based in India. She has diverse experience in documentation, spanning more than 10 years with the ability to transform complex concepts into clear, concise, and user-friendly documentation.