- BLOG

How to Prevent Trucks from Crossing Restricted Bridges?

Published: February 11, 2026

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

What if one wrong turn could cost you a bridge, a truck, and a life? Every year, trucks strike restricted bridges because of height, weight, or routing violations, causing massive infrastructure damage, safety risks, and costly delays for fleets. Fleets can eradicate bridge strikes and make sure that all routes are safe before the wheels even turn with the correct combination of data, routing intelligence, and operational discipline.

Want to learn how to keep your trucks off restricted bridges and your operations running safely? The entire blog will reveal useful strategies, technologies, and best practices to prevent restricted bridge crossings.

Restricted bridges are critical control points in transportation networks where structural capacity, geometric design, or safety policy imposes limits on the types of vehicles that can cross. These boundaries are based on engineering studies of load-carrying components, fatigue life, clearance wrappings, seismic robustness, and hazard exposure to neighboring populations and infrastructures. Common restrictions include:

Certain limits are established and imposed by transportation authorities by conducting inspections, structural ratings, bridge inventories, and regulatory measures like state DOT policies and federal load rating standards. They are conveyed through physical signs, computerized bridge databases, permit systems, and occasionally sensor-monitored.

The consequences of non-compliance are systemic, not just local. One bridge strike can cause hours or days of closure, disruption of regional supply chains, and emergency repairs worth millions of dollars. It also results in the loss of public confidence and puts fleets at legal liability and reputational harm.

Here are the main reasons why trucks still end up on restricted bridges:

Digital maps are abstract representations of the real world, and when the abstractions fall behind reality, danger arises. A lot of navigation systems do not update bridge clearance, temporary construction limits, load postings, or emergency closures in a timely manner.

Others rely on crowd-sourced or fixed datasets, which are not able to reflect seasonal constraints, recent inspections, or fast infrastructure modifications. This results in a data reality gap, where routing intelligence is optimized against an old digital representation of the road network. It directs drivers into corridors that no longer exist as safe or lawful in the real world.

Truck movement is governed not only by geometry, but by physics and regulation. The height of the vehicle, gross weight, the number of axles, the type of trailer, the hazmat category, and the turning radius have an essential impact on the paths that can be taken. However, routing logic that is optimized to support passenger vehicles is still being used by many fleets.

Systems simplify complex compliance to simple distance or time optimization without putting vehicle profiles and regulatory constraints directly in route computation. This collapses multi-dimensional freight feasibility into car-centric shortcuts, making violations an inevitable outcome rather than an exception.

Physical signage is often the final safeguard, but also the weakest. Signs may appear too close to restricted bridges, offer no safe detour, or be inconsistent and obscured in dense urban environments. In industrial zones, ports, and yards, the last mile is filled with small roads, temporary walls, and informal reroutes that cannot be detected by digital maps.

This forms a cognitive overload zone in which drivers have to process complex spatial signals within a few seconds, and in most cases, they have no time to make corrections after they are set on a course.

Despite the presence of good data and tools, human beings are fallible. The real-world decisions are influenced by fatigue, stress, overconfidence, and habituation. When drivers face tight delivery deadlines, they may prioritize speed over strict compliance, especially if shortcuts have worked before.

Systemically, this is not just a personal mistake, but a systemic consequence of working conditions that make speed more visible than safety and force human judgment to make risky compromises.

The current freight processes are fragmented systems and interfaces with planners, dispatchers, permit teams, and drivers. A planner can create a legal route, but the driver can get simplified turn-by-turn directions devoid of context, such as clearance limits or the reason why there is a restriction.

Updates during transit may not propagate cleanly. This division leads to the loss of semantics, with safety intent, contained in planning, not being translated into action, and the feedback loop between intelligence and action is broken.

Even when permits are issued, they represent a snapshot of feasibility at a moment in time. Accidents, construction works, weather, or changes in enforcement can invalidate routes during a journey.

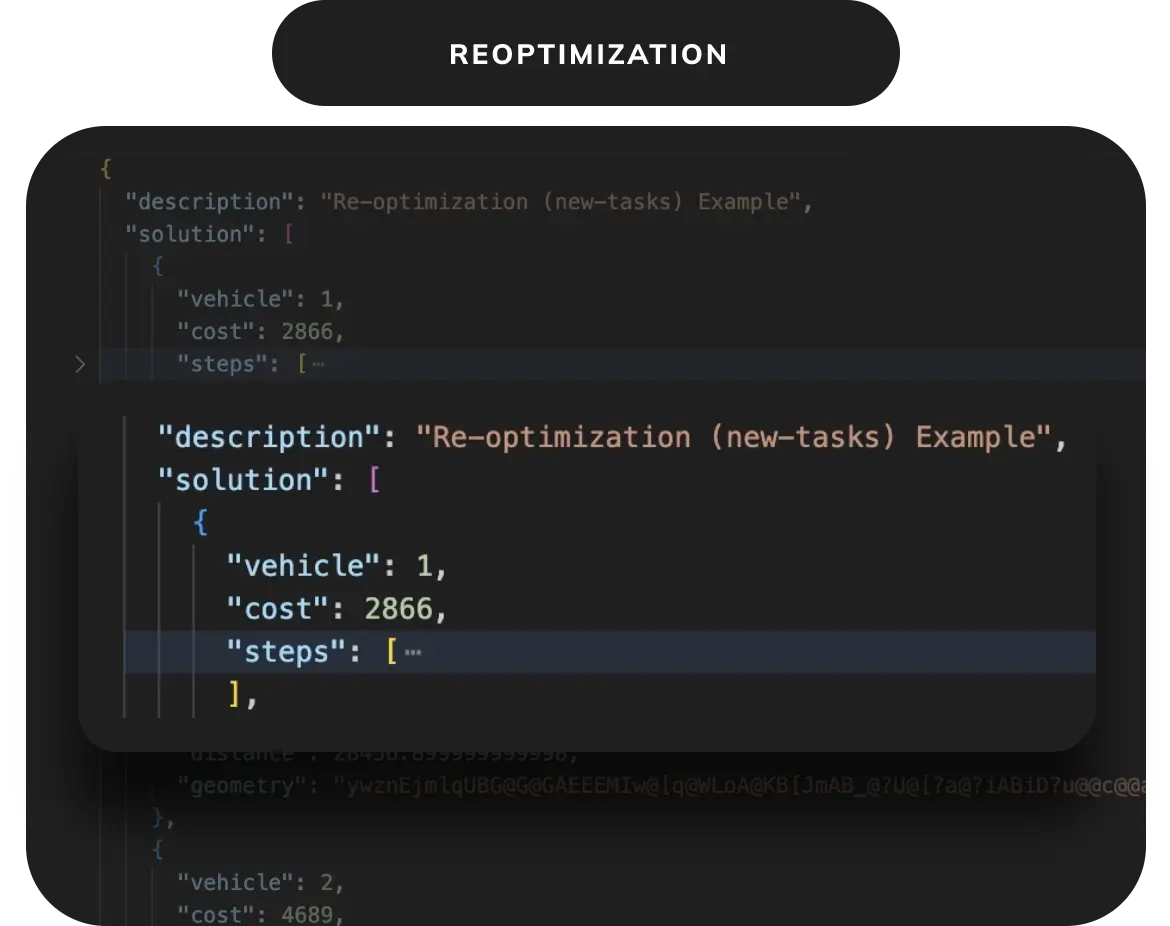

Without continuous re-evaluation, drivers may unknowingly drift into restricted corridors. This is indicative of a larger problem: compliance as a one-time permission and not as a constantly validated state that needs to change with the changing realities.

Many bridges were built decades ago for lighter, smaller traffic volumes. The freight today is more frequent, higher, and heavy, and the infrastructure capacity tends to decrease with age. This structural incompatibility adds more limited bridges and narrows safe corridors, which results in routing being more complex. Violations are not simply routing failures, but manifestations of tension in the system between the aging public infrastructure and growing economic pressure.

Here are the risks of crossing restricted bridges that every fleet must understand and avoid:

Restricted bridges are often aging assets already operating near their structural limits. Stresses can be higher than the design limits when overweight or over-height trucks pass over them and cause cracks, joint failures, or, in severe cases, partial or total collapse.

The structural fatigue is accelerated by each violation, reducing the life cycle of bridges and transferring the latent expenses to the systems of public infrastructure and taxpayers. Conceptually, every strike is not an isolated event, but a compounding degradation of shared assets.

Bridge strikes and overload collapse endanger drivers, those in the immediate vicinity of the motorist, pedestrians, and first responders. Excessive height effects may shear trailers, and debris may fall on the road below, and overweight crossings may produce unexpected structural failures. These accidents transform the routing errors into life-threatening experiences, making safety the most critical dimension of compliance.

Violations provide carriers with fines, permit revocations, insurance claims, and civil lawsuits. In extreme situations, fleets can be subject to the cost of infrastructure repair and losses due to closures or accidents. Legally, limited bridge crossings are not only a failure in operation but also a violation of the duty of care with long-term financial and regulatory implications.

Bridge accidents cause road closures, slow shipments, loss of cargo, and emergency detours or transloads. In addition to direct losses, recurrent breaches destroy customer, regulatory, and community trust. Non-compliance transforms into brand and reliability risks, which determine long-term competitiveness in freight markets.

Violation Type | Typical Fine Range | Who Pays |

Over-height bridge strike | $500 to $10,000+ | Carrier/Driver |

Overweight crossing | $1,000 to $25,000+ | Carrier |

Ignoring posted restrictions | $250 to $5,000 | Driver/Carrier |

Causing bridge damage or closure | $10,000 to $100k+ | Carrier |

Repeat violations | Escalating fines | Carrier |

Here are the key data needed to prevent restricted bridge crossings and ensure safe, compliant routing:

Here is a realistic and end-to-end model that fleets can adhere to in order to avoid limited bridge crossings in a systematic way that involves technology, process discipline, and human supervision.

Keep up to date with clearance, load rating, and restriction data of DOTs and certified providers. This is what the physical feasibility envelope of your freight network is. Every routing decision becomes grounded in structural engineering reality rather than abstract connectivity, ensuring that digital routes never exceed what infrastructure can actually support.

The update maps are used to update the digital representations with the physical world on a regular basis to show construction, seasonal posting, inspection, and emergency changes. This avoids the data reality gap, in which routing decisions are made based on obsolete infrastructure, and that blindly directs trucks into newly constrained routes.

Maintain only one reliable source of truth between planning, dispatch, and in-cab systems. This will foster situational awareness throughout the organization. This way each actor will be working based on the same compliance intelligence. There will be no divided interpretations that lead to safety degradation at the point of handoff.

Record height and weight, number of axles, distance between axles, type of trailer, and hazmat category for all assets, making them explicit constraint models rather than generic fleet units. This changes routing into a vehicle-agnostic navigation to physics-aware decision-making that is dependent on the interaction between the truck and infrastructure.

Real-time update load dimensions and weights using TMS or WMS to ensure that routing is based on the actual physical condition of a certain trip and not presumed averages. This holds feasibility in reality, as compliance varies with each load, not only with each vehicle. Block dispatch except in case of complete and verified profiles. This renders data integrity a control to execution, making safety a part of operational control as opposed to accuracy a clean-up activity.

Plan only with systems that incorporate truck constraints into route computation to ensure that infeasible routes are never computed. Use compliance-approved paths as default execution paths to maintain intent between planning and driving. This avoids the loss of safety logic during handoff, and that is what is designed is what is implemented.

Avoid reversion to car-based navigation aids, which reduce freight viability to time or distance optimization. It eliminates shortcuts, which substitute structural safety with seeming efficiency.

Design routes that are feasible and then send in permits such that permits legitimize reality and do not define it. This grounds regulatory authorization on physical reality rather than permitting the paperwork to guide unsafe tracks

Store the permit restrictions in the navigation guidance so that legality does not go along the route as a disjointed document. This transforms permits living constraints, which are actively directed towards execution.

Develop the knowledge of the purpose of limits and responding in the context of uncertainty. It transforms drivers into active agents of safety, but not just followers of instructions. Conceptually, this aligns human judgment with system intelligence.

Make it clear that compliance is of greater importance than speed, and put safety as a shared operational ideal. This works against time pressure and redefines success as being safe, rather than fast.

Here is how AI and geospatial intelligence transform routing from simple navigation into an intelligent, learning system for preventing restricted bridge crossings:

Traditional maps describe connectivity. Geospatial systems based on AI can become compliance engines by adding such properties as bridge clearances, load ratings, turn geometry, hazmat rules, and time-based restrictions as part of the network graph. The map is an evolving passive reference layer to a dynamic decision system. It provides a representation of what is physically and legally possible to each vehicle, and every route is a computation aware of compliance.

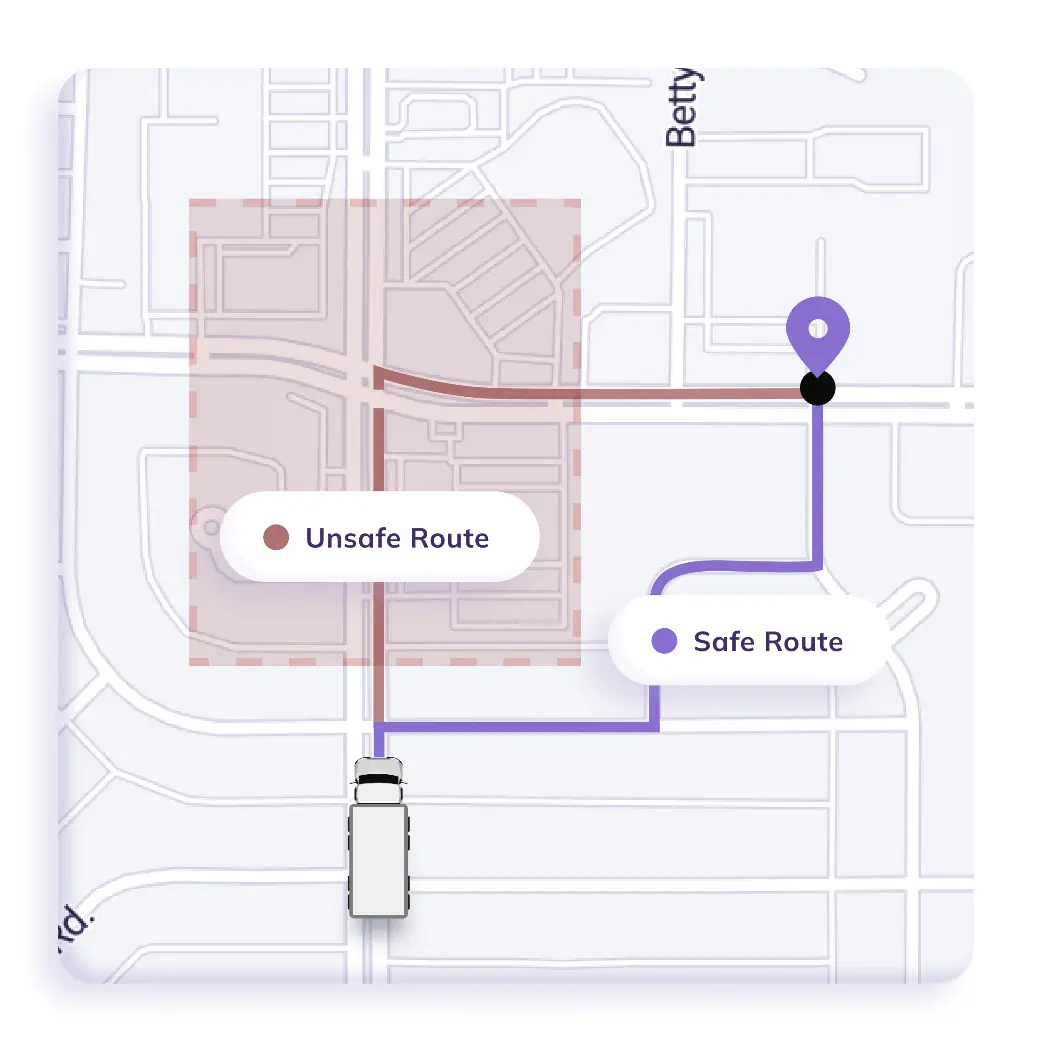

In constraint-aware routing, the physics of vehicles and infrastructure constraints are considered as inputs to pathfinding. The search space is shaped by height, weight, axle spacing, and approach geometry, and thus, unsafe paths are never formed. This reframes routing, as it is no longer a search for the shortest path. It becomes a search for a feasible path. Navigation becomes a property of the algorithm, not a post hoc test. Safety also becomes a property of the algorithm, not a post hoc test.

Based on historical violations, near-misses, route patterns, vehicle types, timing, and environmental conditions, AI models are trained to predict the likelihood of a planned trip to experience limited infrastructure. Rather than determining the question of whether a route is allowed, systems determine the probability of a route failing in actual conditions. It changes deterministic validation to probabilistic risk management, which allows proactive redesign of routes, loads, and schedules.

The overlay of LLMs on geospatial results converts technical limitations into comprehensible, contextual descriptions like low clearance under a given bridge or weight restrictions because of structural rating. This makes black-box restrictions comprehensible and makes the behavior of drivers consistent with the intent of the system. It bridges the cognitive divide between algorithmic decision-making and human decision-making in the cab.

Every deviation, close call, and violation becomes training data for both AI risk models and routing refinement. In the course of time, the systems internalize not only formal limitations, but also practical patterns of operations in which risk manifests itself. The network learns through experience, and it transforms inactive rules into adaptive safety intelligence, which becomes progressively better with each trip.

Here is how fleets can integrate restricted bridge prevention directly into TMS and dispatch workflows, turning safety into a native part of daily operations rather than an afterthought:

Here are the key technologies fleets rely on to keep trucks safely off restricted bridges:

Technology | Purpose | Primary Benefit |

Truck-Specific Routing Engines | Routes based on height, weight, axles, hazmat | Blocks unsafe paths at planning |

High-Fidelity Geospatial Maps | Adds clearances and load limits to maps | Makes maps compliance-aware |

Real-Time Traffic & Closures | Feeds live construction and incidents | Prevents drift into new risks |

Geofencing & In-Cab Alerts | Warns near restricted zones | Last-mile safety net |

AI Risk Prediction | Flags high-risk trips early | Proactive prevention |

Dynamic Rerouting | Replans during deviations | Keeps compliance in motion |

Telematics & ELD Integration | Tracks live vehicle behavior | Closes plan-to-field loop |

LLM Driver Explanations | Explains restrictions in plain language | Improves driver decisions |

TMS & Dispatch APIs | Embeds checks in workflows | Makes safety native to ops |

Permit Integration | Aligns permits with routes | Keeps legality tied to paths |

Cloud Routing Infrastructure | Scales routing and analysis | Reliable at fleet scale |

Analytics & Near-Miss Learning | Learns from incidents | Builds adaptive safety |

Below are the key challenges in preventing restricted bridge crossings that fleets, cities, and technology providers must address to build truly resilient safety systems:

Selecting the right routing platform is not just a technology decision. It is a strategic choice that determines whether safety and compliance become embedded capabilities of your operations or remain manual checkpoints. The right solution should align engineering reality, operational workflows, and long-term scalability into a single intelligence layer.

NextBillion.ai provides truck-specific routing engines, where height, weight, axle configuration, hazmat class, and bridge clearances are directly incorporated into route calculation. The platform uses only physically and legally valid paths, rather than filtering unsafe routes post-factum. This converts distance optimization routing to compliance intelligence routing, and all routes are compliance-aware by default.

At the core of prevention is accurate infrastructure data. NextBillion.ai adds more features to road networks with vertical clearance, load ratings, turn restrictions, lane geometry, tolls, and construction zones. This geospatial depth enables fleets to know not only the direction of the roads, but what they are capable of bearing. It transforms maps into functional safety layers and not mere tools of navigation.

NextBillion.ai offers API-first routing, distance matrix, and geocoding solutions that are compatible with TMS, ERP, and dispatch systems. This allows validation of routes on creation of loads, real-time checks of feasibility, and up-to-date information without interrupting core operations.

NextBillion.ai enables rerouting of trucks in real time under truck constraints as traffic, closures, weather, or enforcement conditions vary. On deviations, fleets will automatically come up with safe alternatives to guarantee compliance during execution, and not only at dispatch. This establishes living paths, which are responsive to reality rather than presumptive conditions.

NextBillion.ai is designed to provide cloud-native performance and support high-throughput and low-latency routing within regions and fleets. Regardless of large-scale simulation, what-if, or real-time route calls, the platform is elastic to achieve operational peaks. Such reliability is critical to fleets that need to assess thousands of routes without reducing safety or speed.

NextBillion.ai offers the spatial truth layer, which AI and LLM systems require to make correct reasoning. AI models can be fed route outputs, constraint explanations, and map attributes, which predict risk, and LLMs can be fed route outputs, constraint explanations, and map attributes, which explain why routes are constrained in human terms. This puts language and intelligence on a firmer foundation of geography in the real world, so that abstract reasoning does not lose touch with physical reality.

NextBillion.ai uses maps as a compliance infrastructure to drive prevention, simulation, and decision-making. Fleets are able to make routes safer, experiment, and impose restrictions at scale, making geospatial intelligence the foundation of confined bridge avoidance plans.

Preventing trucks from crossing restricted bridges demands more than warnings. It demands precise data, truck-specific routing, real-time intelligence, and a safety-first culture that is instilled in day-to-day operations. Combining geospatial awareness, AI-enhanced risk forecasting, and responsible processes enables fleets to transition to proactive prevention. It ensures infrastructure, drivers, cargo, and reputation are not harmed, while ensuring freight deliveries are safe and reliable.

Ready to turn your routes into compliance engines? Learn how NextBillion.ai can assist you in avoiding limited bridge violations using constraint-mindful routing and geospatial intelligence in real time. Talk to our team today to learn more.

Trucks cross restricted bridges due to outdated map data, car-centric routing, poor signage, and last-mile navigation confusion. These gaps prevent drivers from seeing height, weight, or axle restrictions in time.

Fleets can prevent bridge strikes by using truck-specific routing with verified clearance and load rating data.

This ensures restricted bridges are excluded before routes are dispatched.

Accurate bridge clearance, load ratings, road geometry, vehicle dimensions, and real-time construction updates are essential. Without this data, routing systems cannot reliably assess physical feasibility.

Truck-specific routing embeds height, weight, axle, hazmat, and permit constraints directly into route calculation.

This blocks unsafe or illegal paths instead of correcting violations after they occur.

Yes. AI predicts high-risk routes, flags potential violations early, and supports proactive rerouting. This shifts fleets from reactive incident response to preventive safety control.

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.