Table of Contents

Middle mile logistics handles all the steps and processes involved in the transportation of goods from a warehouse or fulfilment center to a second facility that ships the items to either stores or customers. Bulk transportation is the focus here. Last mile logistics tends to be the most expensive part of your supply chain with considerably higher transportation costs than middle mile delivery since it focuses on individual deliveries.

An efficient middle mile logistics process would need to balance cost, speed, inbound logistics, outbound logistics, inventory management, item picking, and safety effectively. Last mile logistics is the ‘face’ of the entire operation: any errors, mishaps, or delays are immediately noticeable and can greatly affect their shopping experience. The importance of this stage has grown considerably over the years as more and more consumers opt for home deliveries. With home deliveries, the expectation is speedy deliveries with convenient delivery options and real-time tracking, preferably at no extra cost.

What Are the Common Challenges Companies Face When Implementing Middle Mile Logistics and Last Mile Logistics?

We’ve shed some light on the importance of middle mile and last mile logistics in the last section. Both aren’t without their challenges. It is important to understand what these are if you are to overcome them to stand out among your competitors and be the go-to choice for customers.

Common middle mile logistics challenges are as follows:

Complex Routing

Finding the most efficient routes between warehouses/fulfillment centers is key for effective middle mile delivery. Given that middle mile delivery needs to coordinate across various modes of transportation, custom clearances, legal considerations, different regional rules, and unexpected disruptions like extreme weather conditions or political unrest; complex routing is a problem that needs to be solved.

Inventory Management Issues

Warehouses can face issues like late shipments, lost assets, and inventory discrepancies. Losing inventory is another challenge that plagues middle mile delivery operations.

Technology Integration Challenges

To reduce the occurrences of inventory management issues, companies should look to modernize their warehouse operations. By using reliable tracking technology, they can cut down on lost assets considerably while maintaining better inventory records. A common challenge here is making the move from an analog setup to a digital one. It might cause short-term pain, but it’s a necessary step to optimize middle mile logistics.

Due to an increasing need for fulfillment speed, and accuracy, companies also need to join systems for a single source of truth cause multiple touchpoints tend to dilute transport visibility and control. Partners and stakeholders working in silos without real-time supply chain intelligence might cause faulty decision-making. Missing, delayed, or inaccurate data from the first mile only piles on more trouble and reduces the chances of an effective delivery process.

Common last mile logistics challenges are as follows:

High Operational Costs

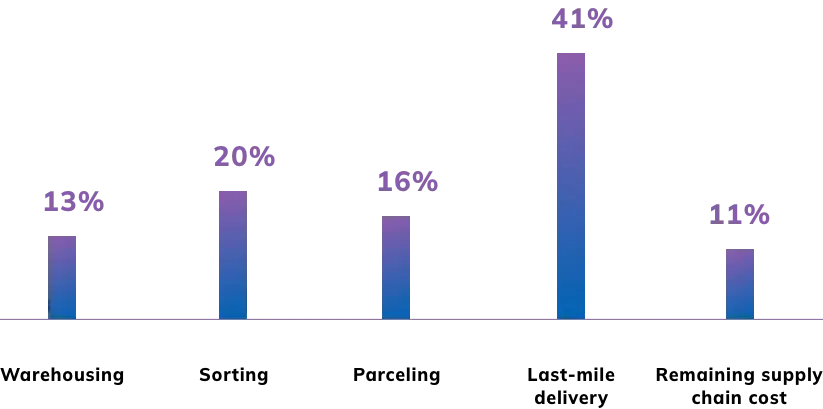

Last mile delivery still tends to be the most expensive component of the supply chain (see figure below). In most cases, retailers have no choice but to absorb last mile delivery costs. Why? Customers usually abandon online shopping carts if they see any unforeseen additional costs. Drivers’ salaries, fuel costs, and the cost of fleet operations are some of the expenses in the last mile. Managing failed deliveries and returned products adds to the high operational costs during last mile delivery.

Meeting Customer Expectations

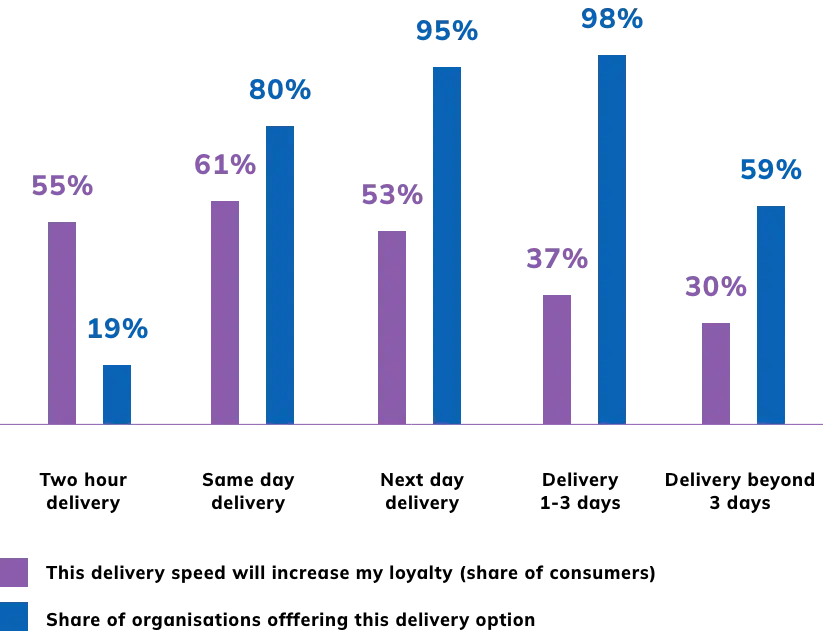

According to a survey by AlixPartners, customer expectations have risen steeply: from simplified online shopping to fast and free delivery. Speed is paramount; customers want home delivery within 3.5 days in 2024. If the retailer fails to meet this need, close to 25% of clients won’t mind shopping elsewhere.

While customer expectations keep rising, a lot of companies are finding it difficult to keep up. The majority of executives are prioritizing reducing the total cost per order for last mile delivery. This tradeoff between speed and managing cost is another key challenge that manufacturing companies will need to navigate in the future.

How Does NextBillion.ai Solve Middle Mile Logistics and Last Mile Logistics Challenges?

We’ve talked about the challenges that manufacturing companies face while trying to optimize middle mile logistics and last mile logistics operations. Now, let’s take a look at how NextBillion.ai solves these problems:

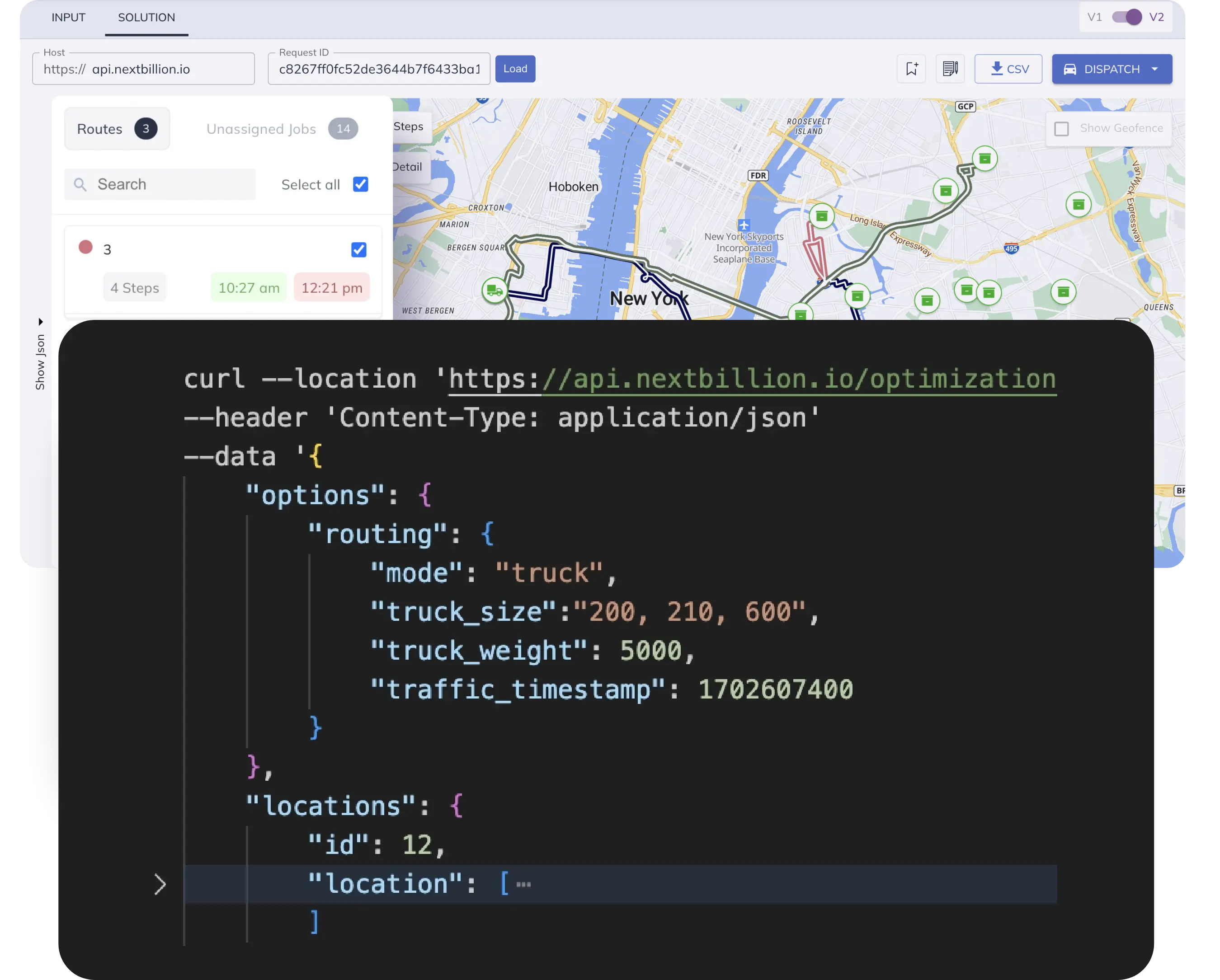

- Advanced routing algorithms: With NextBillion.ai’s advanced Route Optimization API, you can easily enhance fleet utilization and fit unique operational needs with 50+ hard and soft routing constraints. The API also allows you to plan for different cargo types and truck capacities: optimize loads for multi-compartment trucks, and ensure resilience and efficiency. With the ability to handle complex variables and constraints such as time windows, capacity, and vehicle availability, the Route Optimization API has been built to meet the specific needs of your business. One of the key features that sets NextBillion.ai’s Route Optimization API apart is its ability to carry out truck-specific routing, a feature that allows the routing engine to suggest routes that are safe for the given truck dimensions.

- Cost optimization: NextBillion.ai offers a pricing structure that flexibly adjusts to your operational volume and business model, unlike other alternatives where rigid pay-per-call APIs that only factor in the number of API requests. The pricing model also improves cost predictability and ensures accurate cost modeling.

- Enhanced Customer Satisfaction: Efficient clustering of orders based on travel time, distance, and proximity to each other enhances resource allocation, routing, and dispatch efficiency, not to mention a faster arrival time of products. The faster your arrival time, the more pleased your customers tend to be.

- Seamless Technology Integration: The platform integrates with transportation management systems and telematics that facilitate the plugging in of routing and fleet tracking data from and back into your existing systems like Geotab, Samsara, and ServiceNow. The NextBillion.ai platform is modularly designed, allowing you to easily begin with any individual module or choose from leading industry solutions.

- Scalable: NextBillion.ai’s platform design puts scalability at the top. NextBillion.ai is fully capable of handling massive datasets; irrespective of whether you manage a nationwide network or hyperlocal operations. NextBillion.ai optimizes the routes for thousands of locations and supports large matrices to ensure smooth operations aligned with your business growth. NextBillion.ai offers a cloud-agnostic architecture that you can access through REST APIs or deploy on-premise within your data center or cloud environment. This flexibility lets you handle performance, scalability, cloud costs and your compliance and security requirements.

Solving Middle Mile Logistics and Last Mile Logistics Challenges: A Case Study

Let’s talk about a real-world example.

What do you do when you are an AI-driven trucking logistics startup and your distance matrix API isn’t the right fit?

You look for an alternative.

NextBillion.ai was approached by a US-based startup whose primary goal was to improve fleet operations for its customers. The startup has a roster of 60 trucks spread across Canada, the United States of America, and Mexico.

Two reasons why the distance matrix API they were previously using was a bad fit for them:

- Excessive cost: They were using the API pretty frequently — to the order of millions of calls. The fixed pricing model of the API meant it was costing the startup an arm and a leg.

- Future threat: The fixed pricing model also meant that it wouldn’t be scalable for an early-stage company.

Enter NextBillion.ai’s Distance Matrix API. Here’s how it sized up against the previously used Distance Matrix API:

- Truck profiles: NextBillion.ai’s Distance Matrix API has truck profiles, allowing for more finely tuned and optimized truck-specific routing. NextBillion.ai’s API: 1, previous API: 0.

- Customized pricing: A key factor that tipped the decision in NextBillion.ai’s favor was the flexibility in building a customized quote that suited their expected volume of API calls. A tailored asset-based pricing model that let them decide how many trucks would be used each month allowed them to accurately predict costs.

- Scalability: Generally, standard distance matrix APIs offer a 25 x 25 matrix size. NextBillion.ai’s APIs support matrices of up to 5000 x 5000 elements, allowing them to calculate ETAs and distances between 5000 origins and destinations in a single call. This meant that if they chose NextBillion.ai, they’d be working with a product that scales well alongside them.

- Low Latency: With the large number of calls being made and the scope for rapid business expansion in the short term, raw speed was important to the customer. NextBillion.ai’s API ensured quick responses to keep up with time-sensitive use cases. The company ended up achieving a 30% reduction in API costs thanks to NextBillion.ai’s Distance Matrix API.

Wrapping Up

Getting middle mile logistics and last mile logistics right will give you a competitive edge. However, it might be difficult to execute with rising costs, customer expectations, and the need to eliminate data silos for more efficiency.

That’s why a solution like NextBillion.ai can be useful. Schedule a demo today to see if it’s the right fit for you.

Ready to get started?

Request a DemoTable of Contents