Table of Contents

What is Cold Chain Logistics?

Cold chain logistics is a process that aids in the safe transportation of temperature-controlled products and items via thermal and refrigerated packing methods. This method prevents the products from spoiling or rotting and has an impact on every stage of the supply chain. This method also includes the utilization of temperature-controlled warehouses for storage and cold-insulated vehicles for product transportation.

Since the pandemic, there has been significant growth in cold chain logistics. The demand for receiving cold chain products like vaccines, food, beverages, dairy products, pharmaceuticals, etc, is increasing among consumers across the world. The cold chain logistics service is a crucial part of businesses as it ensures the smooth flow of the supply chain and increases customer satisfaction.

Key Elements of Cold Chain Logistics

Cold chain logistics is crucial for efficient supply chain management and optimizing complex logistics processes. Below are some of the significant elements for effective cold chain management:

- Cooling System: The cooling systems are used to lower the temperature of the goods; once favorable temperature conditions are achieved, these products are taken for processing.

- Monitoring System: The items transported in cold chain distribution are temperature-sensitive, like vaccines; hence, it is important to ensure the integrity of these products is not compromised. The chances of goods spoiling are significantly reduced by a reliable temperature monitoring system.

- Cold Storage: Cold storage is a vital component of cold chain distribution. It ensures that perishable products are safe and fresh for end users. Substances like liquid nitrogen are used to freeze the temperature of these perishable commodities.

- Cold Transport: It is another crucial component of cold chain logistics. It helps in the transportation of goods and commodities while maintaining integrity and favorable temperature conditions.

- Cold Distribution: It involves the distribution of cold chain products to various destinations to meet customer demands. It increases the efficiency of cold chain logistics companies by reducing transportation costs, improving inventory management, and increasing productivity.

How does Cold Chain Logistics work?

To preserve quality and maintain the safety of temperature-sensitive products, the cold chain manages a limited temperature range throughout the entire supply chain. The working of the cold chain can be divided into five steps:

- The first step is to receive goods from suppliers. It involves uploading goods from trucks onto crates, which are then moved to storage rooms and deep-frozen as per their requirements.

- The goods or products are stored in a temperature-controlled environment. Depending upon the agreement between parties involved in a given shipment, this storage can be a supplier’s warehouse or any third-party facility.

- The next step is to prepare goods for shipping purposes. It includes labeling and packing goods for final delivery.

- Now the packaged goods are loaded for final shipment into the designated cold chain fleet. These fleets involve temperature-controlled trucks for last-mile delivery.

- The final step is to deliver temperature-sensitive goods to the respective customer.

Significance of Cold Chain Logistics

The effective use of cold chain logistics has a significant impact on enterprises like the food, beverage, and pharmaceutical industries. Some of its significant advantages are:

- Cold chain logistics plays an important role in improving the security of the global food industry. It facilitates the supply of the best-quality nutrition and medicine to remote locations worldwide.

- It prevents the spoilage of perishable commodities, thereby lowering inventory replacement costs and increasing revenue per transportation.

- Cold transportation boosts the new market opportunity and increases the productivity and efficiency of businesses.

- Due to cold storage, customers receive products in better condition, thereby increasing customer satisfaction and the company’s reputation.

- It helps to establish better compliance with regular norms around food and medical product shipment.

Challenges of Cold Chain Logistics

The fluctuations in temperature can make cold chain shipping a challenging process. Some significant challenges in cold chain logistics are:

- Containment Issues: The cold chain storage facilities are breeding grounds for germs and bacteria. Any mismanagement in the storage of goods or damage to freezers can cause microbial containment. Thus, cold chain companies need to monitor cold storage and freezers regularly.

- Transport Delay: Any transport delay or breakdown can impact the whole cold chain supply system. If a transport vehicle, such as a truck, collapses, it will cause a loss of company revenue and a waste of time and money. Also, temperature-sensitive goods are likely to be spoiled or degraded due to these transition delays.

- Disrupted Temperature Control: Cold chain logistics is all about the safe transportation of perishable goods. If temperature-sensitive goods like pharmaceuticals, frozen meat, frozen vegetables, or ice cream are exposed to temperatures outside the recommended range, they will become unstable and will be hazardous to health.

- Damaged Products: It is one of the biggest challenges for cold-chain logistics companies. Receiving damaged products, inadequate packaging, and mismanagement in the storage of perishable goods will impact the customer experience and, hence, cause damage to both the company’s profit percentage and reputation.

Cold chain logistics is crucial for the smooth flow of the supply chain and satisfying customer demands. The effective use of the cold storage system has a significant impact on enterprises like the food, beverage, and pharmaceutical industries. Steps like choosing the right vehicle for shipment, prioritizing delivery orders, conducting regular fleet inspections, and providing real-time updates on delivery to customers can help overcome all the challenges cold chain distribution faces.

We know that every business is different and we care about your unique needs.

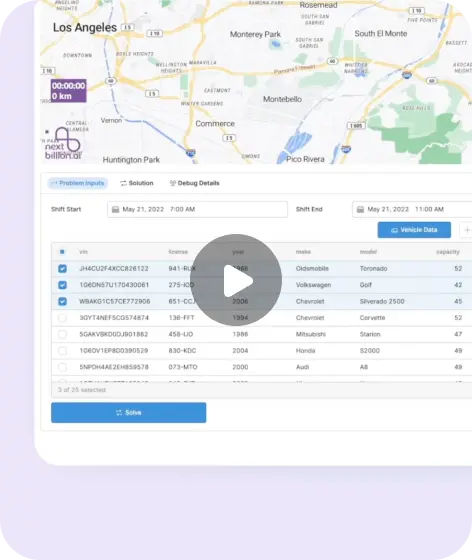

With NextBillion.ai's Map API you get- Large Distance Matrix API with a Matrix size upto than 5000*5000

- Optimal routes with accurate ETAs

- Flexible navigation SDK that's easy to integrate and ready to use for developers

- Quick and accurate location data

- Track and trace routes taken along with other map attributes

- Create custom tiles for your interactive maps. Personalized to fit your brand aesthetic.