- BLOG

Optimizing Warehouse Picking Routes with Indoor Routing APIs

Published: October 17, 2025

Route Optimization API

Optimize routing, task allocation and dispatch

Distance Matrix API

Calculate accurate ETAs, distances and directions

Directions API

Compute routes between two locations

Driver Assignment API

Assign the best driver for every order

Routing & Dispatch App

Plan optimized routes with 50+ Constraints

Product Demos

See NextBillion.ai APIs & SDKs In action

AI Route Optimization

Learns from Your Fleet’s Past Performance

Platform Overview

Learn about how Nextbillion.ai's platform is designed

Road Editor App

Private Routing Preferences For Custom Routing

On-Premise Deployments

Take Full Control of Your Maps and Routing

Trucking

Get regulation-compliant truck routes

Fleet Management

Solve fleet tracking, routing and navigation

Middle Mile Delivery

Optimized supply chain routes

Construction

Routes for Construction Material Delivery

Oil & Gas

Safe & Compliant Routing

Food & Beverage

Plan deliveries of refrigerated goods with regular shipments

Table of Contents

Picking is one of the most labor-intensive and costly operations in a warehouse, often accounting for 50–60% of total operational expenses. As order volumes rise in industries such as e-commerce, retail, and manufacturing, inefficient picking processes can lead to delays, errors, and dissatisfied customers.

Without optimized routing, workers spend unnecessary time walking back and forth, retracing steps, and searching for items. This increases labor fatigue, slows fulfillment, and reduces throughput.

Digital transformation in supply chains now extends to warehouses, where tools such as Indoor Routing APIs play a critical role in streamlining workflows. By applying the same logic that powers outdoor navigation systems, these APIs help optimize picker movements inside complex warehouse environments.

Indoor Routing APIs are specialized navigation tools designed for indoor environments like warehouses, hospitals, airports, or malls. They calculate the most efficient path between two or more points inside a building.

Unlike outdoor routing, which depends on GPS and road networks, indoor routing relies on digital maps of floor layouts, often combined with Wi-Fi, Bluetooth, or RFID signals for location tracking. This makes it suitable for dense environments where GPS is unreliable.

Mapping the Warehouse Layout Digitally

APIs enable warehouse operators to create digital twins of floor layouts, representing racks, aisles, and storage bins.

Generating Optimized Routes for Pickers

Based on pick lists, APIs calculate the shortest or fastest route, minimizing walking distance while ensuring logical sequencing.

Real-Time Re-Routing for Dynamic Changes

If an aisle is blocked or an item is moved, APIs instantly update the route to avoid disruptions.

Integrating With Warehouse Management Systems (WMS)

When paired with WMS, routing APIs automatically generate pick paths for workers and update completion status in real time.

Order grouping, often called batching, involves combining multiple customer orders into a single picking batch. This strategy reduces the total distance pickers need to travel, as several orders can be fulfilled simultaneously. Sequencing then determines the most efficient order in which the batches or order lines are picked to further minimize time and distance.

Once groupings or batches are defined, shortest path algorithms determine the optimal sequence and route a picker should follow inside the warehouse.

Clustering strategies go beyond basic batching by intelligently assigning similar orders or items to the same batch based on proximity or product type, further reducing travel distance.

Combined, these algorithms contribute to a holistic optimization approach that helps in grouping orders for batching, sequencing them logically, calculating shortest routes using indoor-aware algorithms, and refining the process with clustering and wave-based release strategies.

Indoor routing APIs integrate seamlessly with WMS/ERP platforms to deliver actionable pick instructions to workers.

Pickers can access optimized routes via mobile apps, handheld scanners, or AR glasses, improving ease of use.

Warehouse maps and item locations must be updated frequently to ensure scalability across multiple sites.

APIs support strategies like:

APIs calculate the shortest combined path for multiple orders, reducing redundant travel.

APIs learn from historical movement patterns to predict bottlenecks and optimize future paths.

Data from RFID, Bluetooth beacons, or smart shelves enhances location accuracy and ensures up-to-date routing.

APIs reduce order-to-ship times in high-volume warehouses with thousands of daily orders.

In temperature-controlled environments, APIs help workers minimize exposure time while picking.

Big-box retailers optimize restocking and picking routes for store-level replenishment.

Routing APIs help ensure just-in-time material delivery to production floors.

The following features could be some of the future features of Indoor routing:

NextBillion.ai offers APIs and tools for advanced routing, optimization, live tracking, and more. Though much of their marketed focus is on logistics, delivery, fleet, and mapping, some of their tools can be adapted or already are adapted to warehouse picking optimization.

They have a specific solution page for Warehouse Picking Optimization that aims to “streamline the picking process by generating the most efficient routes and picking sequence for workers, reducing travel time and improving order accuracy.”

Route Optimization API supports many constraints and large-scale route problems. Useful for determining efficient sequencing of pick tasks.

For API reference, refer here.

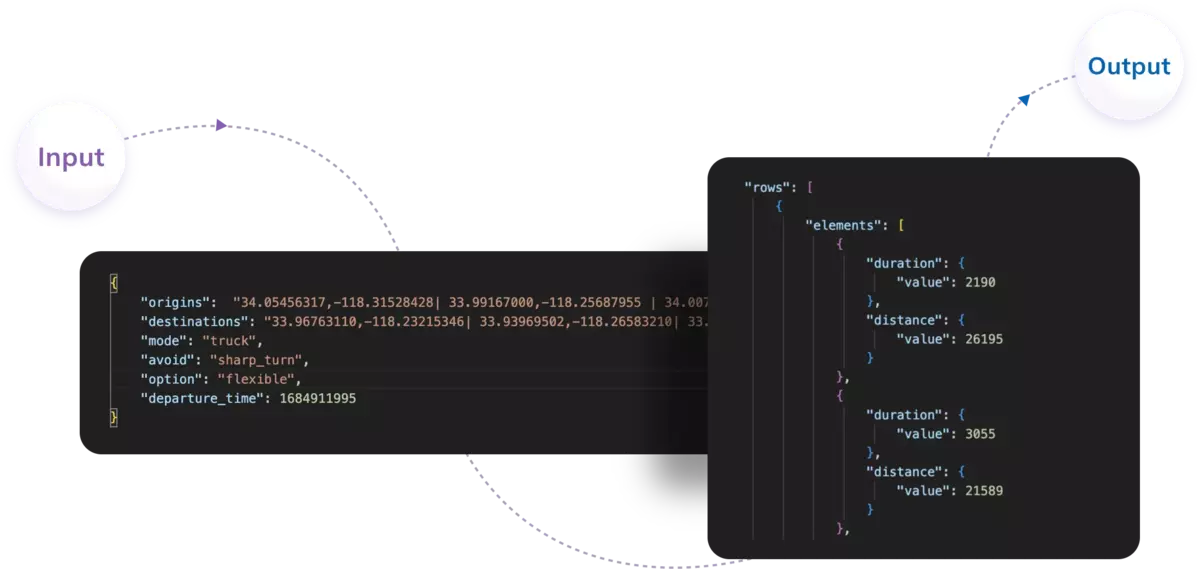

Distance Matrix API for computing ETAs and distances between many origins/destinations. In a picking context this might mean distances between the picker’s current location and multiple SKUs, or between pick points.

For API reference, refer here.

Directions API / Navigation SDK enabling path direction rendering; possibly useful for guiding pickers via mobile or wearable devices.

For API reference, refer here.

Live Tracking and Monitoring helps in real-time tracking of assets or workers; useful if you want to adjust dynamically when someone deviates, someone’s path is blocked, etc.

Clustering / Zone-Based Routing / Task Sequencing features in NextBillion’s toolkit include constraints and sequencing that allow tasks to be grouped or ordered logically. This helps in batch picking or zone picking.

On-Premise Deployment and Private Maps / Custom Map Data is used for indoor warehouse environments, you may need detailed floorplans & precise non-public map data; NextBillion supports custom maps, “road editor” type restrictions, etc.

Here’s how the earlier picking-route-optimization framework can map onto NextBillion.ai capabilities:

Picking Stage / Challenge | How NextBillion.ai Helps |

Mapping the Warehouse Layout Digitally | Use custom map data; potentially use “road editor” or similar tools to define aisles, shelves, no-cross zones, blocked paths. Geofencing can define zones. |

Generating Optimized Picking Routes | Route Optimization API with sequencing constraints: order of picks, zones, batch orders. Distance Matrix API for computing pairwise distances inside a warehouse. |

Real-Time Re-Routing for Dynamic Changes | Live Tracking for worker or asset locations; updates via API, ability to adjust routing or tasks if an aisle is blocked or items are moved. |

Integration with Warehouse Management Systems (WMS) | NextBillion provides APIs to integrate: route-solver API, distance matrices, ability to embed into your system; also tooling to upload tasks (via CSV or programmatically) and get back routes. |

Here’s a suggested plan to use NextBillion.ai for a warehouse picking optimization project.

Gather Warehouse Data

Define Constraints and Objectives

Modeling and Mapping

Integration

Handle Dynamic Events

Performance Monitoring and Feedback Loop

Benefits:

Trade-offs / Considerations:

Compared to generic routing APIs (Google Maps, HERE):

NextBillion allows far more constraints and custom logic.

Supports large scale distance matrices which are essential when many items are in picklists.

Flexible pricing that aligns with business volume.

More control over map data and private map features; handling restrictions.

Indoor vs outdoor: while NextBillion.ai’s product is primarily for routing on road networks, the presence of custom map editing, geofencing, and building indoor-delivery case studies (e.g. robot delivery inside malls, airports) suggests their tools are already being used for indoor applications.

These are possible directions (or ones that NextBillion.ai might already be or planning to) to strengthen indoor picking route optimization:

As warehouses evolve into high-performance fulfillment hubs, the pressure to reduce travel time, cut operational costs, and accelerate order accuracy has never been greater. Traditional picking methods simply cannot keep up with the pace of modern supply chains. This is where NextBillion.ai’s Route Optimization, Distance Matrix, and Indoor Routing capabilities make a measurable difference.

By digitizing warehouse layouts, sequencing pick tasks intelligently, and dynamically adjusting routes in real time, NextBillion.ai enables operations teams to achieve up to 30–50% reduction in walking distances, significantly improving picker productivity and reducing fatigue. Its ability to integrate seamlessly with Warehouse Management Systems, support advanced optimization strategies (zone, cluster, batch picking), and adapt to custom indoor environments ensures a solution that is tailored to your warehouse—not the other way around.

Industry leaders across logistics, retail, e-commerce, and manufacturing already rely on NextBillion.ai to manage complex routing challenges at scale. Their proven track record in delivering enterprise-grade, flexible, and scalable solutions makes them a trusted partner for organizations looking to modernize fulfillment operations.

If your warehouse is struggling with inefficiencies in picking, or if you’re planning to future-proof your supply chain with AI-powered routing, now is the right time to act.

👉 Book a demo with NextBillion.ai today and see firsthand how their APIs can transform your warehouse into a smarter, faster, and more efficient operation.

Prabhavathi is a technical writer based in India. She has diverse experience in documentation, spanning more than 10 years with the ability to transform complex concepts into clear, concise, and user-friendly documentation.