Table of Contents

Managing product returns, repairs, and recycling is no longer an afterthought—it’s now a crucial part of modern supply chains. This process, known as reverse logistics, involves moving goods from the customer back to warehouses, repair centers, or disposal points.

With the growth of e-commerce and rising customer expectations, reverse logistics has become more complex than ever. Companies must balance speed, cost, and customer satisfaction while handling unpredictable volumes and tight time windows.

In this article, I’ll explain how NextBillion.ai’s Route Optimization API helps logistics teams manage reverse logistics efficiently—batching pickups, minimizing return costs, and adapting routes in real-time.

What is Reverse Logistics?

Reverse logistics is the process of moving goods from customers back to the company instead of the usual route from the company to the customer.

In simple terms, it’s everything that happens after a product is delivered—like returns, repairs, recycling, or disposal.

Example:

You order a pair of shoes online. When they arrive, they don’t fit—so you schedule a return.

A driver comes to pick up the shoes and takes them back to the warehouse.

That entire journey (from your home back to the warehouse) is part of reverse logistics.

It’s called “reverse” because the product flows in the opposite direction of regular delivery.

The Challenges of Reverse Logistics

According to a report by Statista, by 2029, the reverse logistics market size is expected to exceed 954 billion U.S. dollars. That’s a massive number—and it reflects just how complicated and costly managing returns, repairs, and recycling has become.

Unpredictable Return Volumes and Pickup Locations

Unlike deliveries, returns don’t follow a predictable pattern. Some days bring a flood of return requests; others barely any. Customers can be spread across wide geographies, making it challenging to batch pickups efficiently. This unpredictability makes planning ahead almost impossible.

Route Inefficiencies and Rising Fuel Costs

Most reverse logistics routes are reactive—dispatched one by one as return requests come in. Without optimization, this leads to inefficient routes, longer drive times, and more fuel burned. With fuel prices constantly fluctuating, that adds up quickly.

Lack of Visibility and Real-Time Tracking

Returns often disappear into a black hole once picked up. Operations teams can’t track them easily, and customers are left wondering when their return will be processed. That lack of visibility slows down refunds, restocking, and repair workflows.

Difficulty Coordinating Pickups with Deliveries

Many fleets handle both deliveries and pickups, but coordinating them can be tricky. Without the right system, drivers either miss pickup windows or drive around with half-empty vehicles, leading to wasted time and higher costs.

Customer Dissatisfaction Due to Delayed Returns or Refunds

People expect fast returns—just like they expect fast deliveries. However, delays caused by poor routing or tracking issues can lead to frustrated customers, bad reviews, and lost loyalty.

These challenges make reverse logistics a tricky part of the supply chain to manage. But with the right tools, they’re solvable.

How NextBillion.ai Solves Reverse Logistics Problems

Managing returns and pickups efficiently takes more than guesswork. NextBillion.ai’s Route Optimization API brings structure, speed, and clarity to reverse logistics—by combining smart routing, real-time updates, and flexible rule-setting.

Dynamic Route Optimization for Pickups

Returns come in at all hours from all places—and that makes routing a moving target. NextBillion.ai helps you automatically generate the most efficient return routes based on current conditions.

As new pickup requests come in or traffic patterns change, the system adjusts routes in real time—without manual rework. It also lets you plan multi-stop routes that handle both forward deliveries and reverse pickups in one trip, improving vehicle utilization and cutting fuel costs.

Custom Rules and API Flexibility

Not every return route is the same. Some drivers need to avoid highways. Some pickups must happen within a tight time window. NextBillion.ai lets you define custom rules for routing—down to the level of road types, time constraints, and vehicle preferences.

Its API integrates easily with your existing systems—WMS, TMS, or custom reverse logistics software—so you don’t need to rebuild workflows from scratch. The result: smarter, automated decisions that speed up return processing.

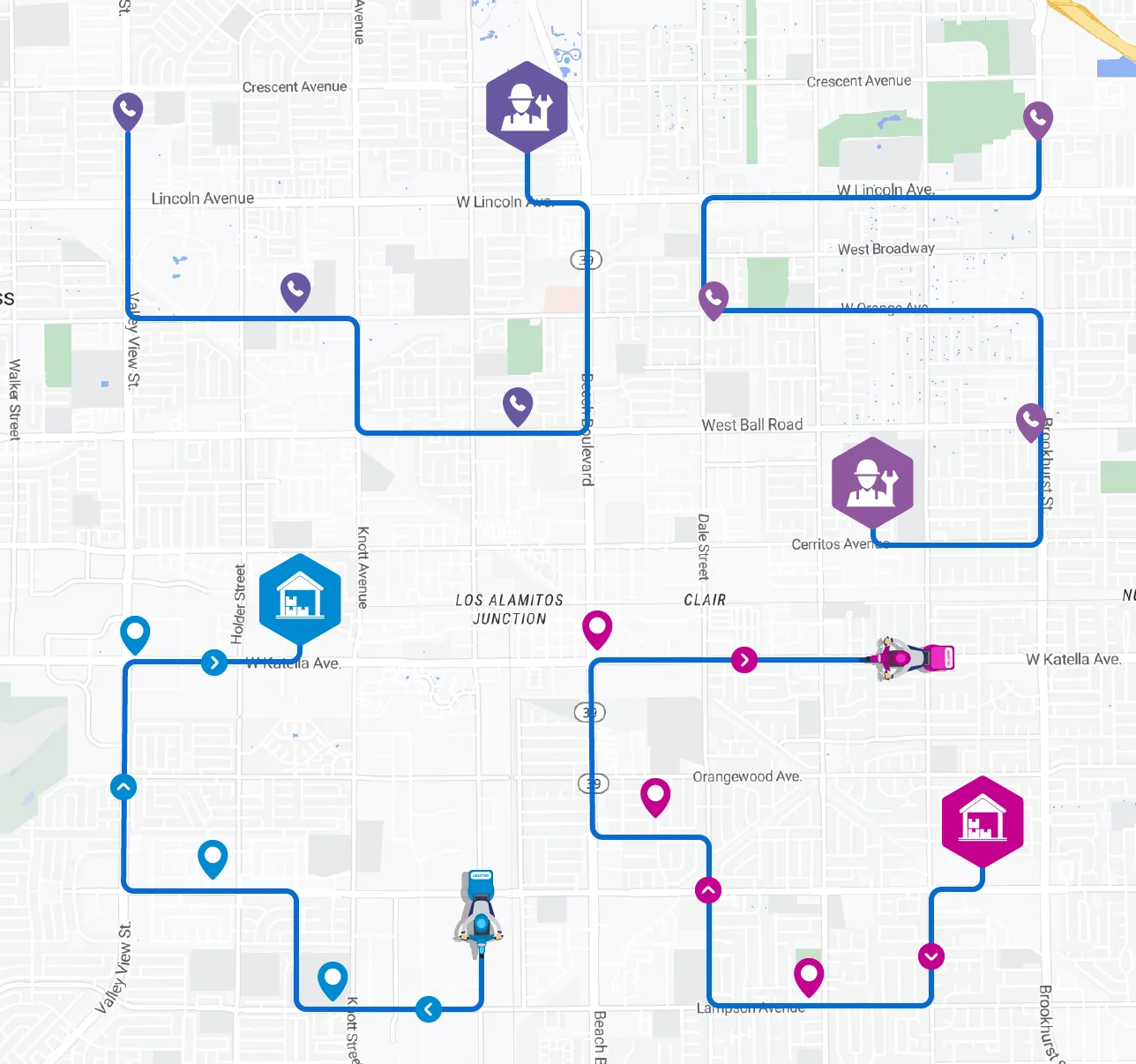

Reverse-Forward Route Consolidation

Sending out vehicles just for returns isn’t always cost-effective. With NextBillion.ai, you can merge return pickups with regular delivery runs to reduce cost-per-mile and avoid empty vehicle legs.

The system helps you design efficient return paths to hubs, depots, or recycling centers—minimizing idle time, fuel use, and carbon emissions in the process.

NextBillion.ai gives you the tools to make reverse logistics faster, smarter, and more sustainable.

How to Use Route Optimization API to Solve Reverse Logistics

In this section, I will walk you through how NextBillion.ai’s Route Optimization API can be used to optimize reverse logistics workflows—i.e., the scheduling, routing, and consolidation of “pickup” tasks (returns, repairs, recycling, etc.) rather than only forward deliveries.

The API treats returns as “shipments” with pickup‑and‑delivery legs, supports rich constraints (time‑windows, vehicle capacities, depot returns, cost limits), and offers dynamic re‑optimization—enabling you to batch customer returns, send drivers back to depots, merge forward and reverse runs, and react in real‑time as new return requests arrive. Key building blocks include:

- Shipments (defining pickup + drop‑off pairs)

- Depots & multi‑trip support (vehicles can return to a depot and head back out)

- Soft/hard constraints (time windows for customer availability, max ride time, cost budgets)

- Re‑optimization (inject late return orders into in‑flight routes)

- Order grouping (batch multiple nearby pickups on one stop)

- Custom cost matrices & objectives (optimize for lowest reverse‑leg cost or carbon)

- Zone‑based allocations (assign returns to regional hubs or specific crews)

- Scalability (up to 10,000 pickup tasks per call; real‑time traffic)

1. Modeling “Returns” as Shipments

NextBillion.ai’s API lets you define a set of jobs (one‑way tasks) and shipments (paired pickup + delivery) in the same request. For reverse logistics, each customer return is:

- A pickup job at the customer’s location, with a “pickup amount” and optional time window when the customer is home

- A delivery job back to a depot, repair center, or recycling facility (specified via the shipment’s delivery leg)

By treating returns as shipments, you automatically get the followingt:

- Paired routing (vehicle must first visit the pickup, then the drop‑off)

- Tracking of load changes (pickup increases the load, delivery decreases it)

- Unassigned‑task reporting when constraints can’t be met

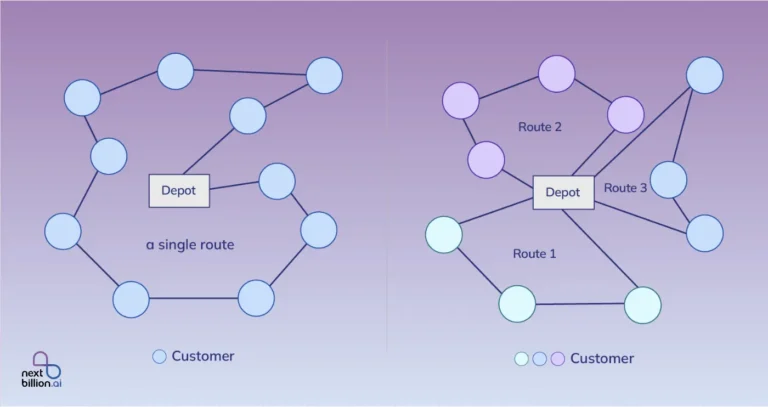

2. Depots & Multi‑Trip Support

Reverse logistics often requires vehicles to return to a depot to unload returns before heading back out. The API’s depots feature lets you:

- Assign vehicles to start/end at a depot

- Specify multiple trips back to a depot (e.g., once capacity is full) within one optimization call.

This ensures returns are continuously consolidated and returned to central hubs without manual routing.

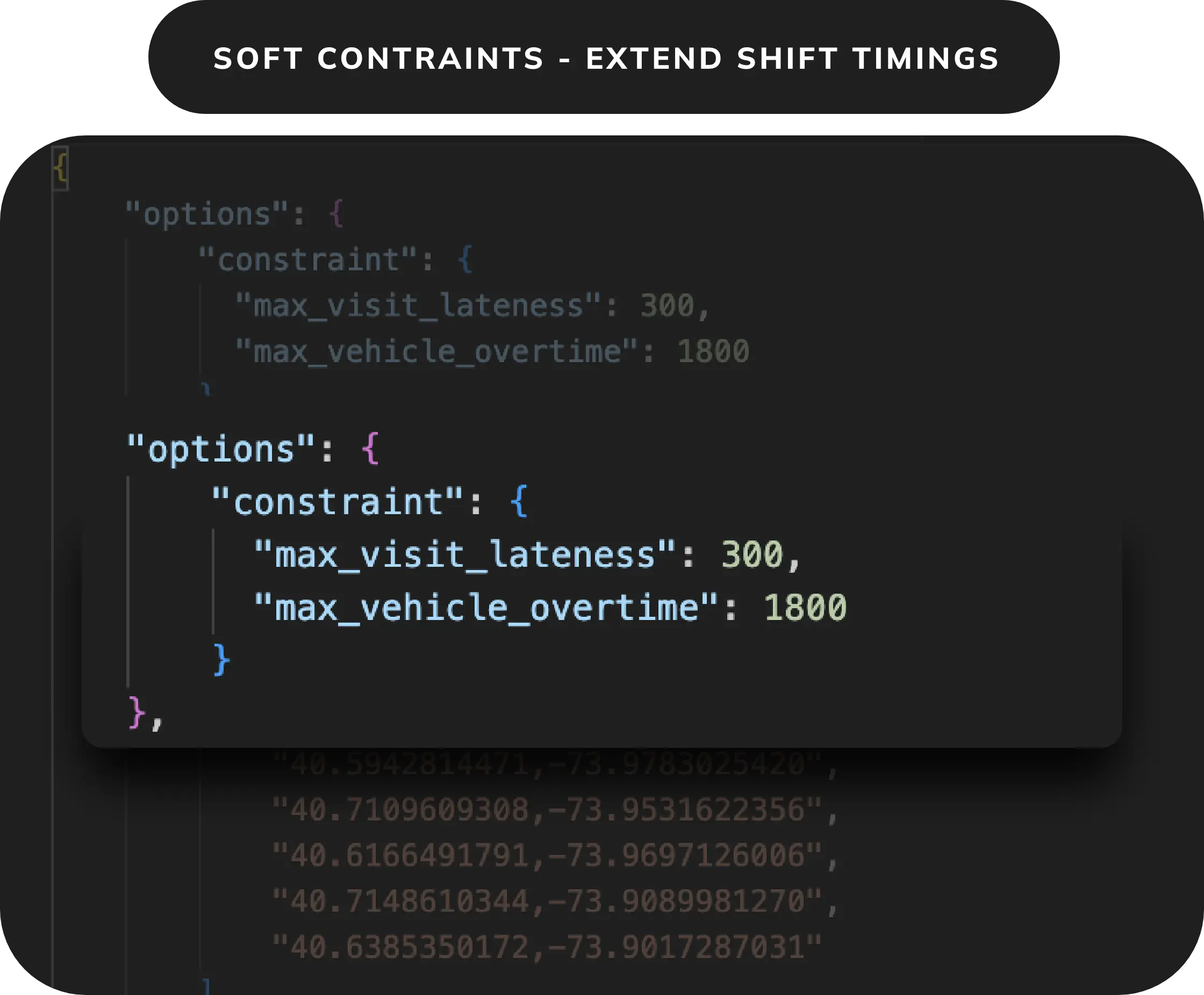

3. Enforcing Time‑Windows and Soft Constraints

Customer pickups have narrow availability windows. The API supports:

- Hard time‑windows on each pickup job, so drivers only arrive when customers are present.

- Soft constraints to allow slight flexibility (e.g., ±15 min) when needed to improve overall efficiency.

- Max ride time to ensure per‑leg durations (e.g., warranty pickup) don’t exceed policy

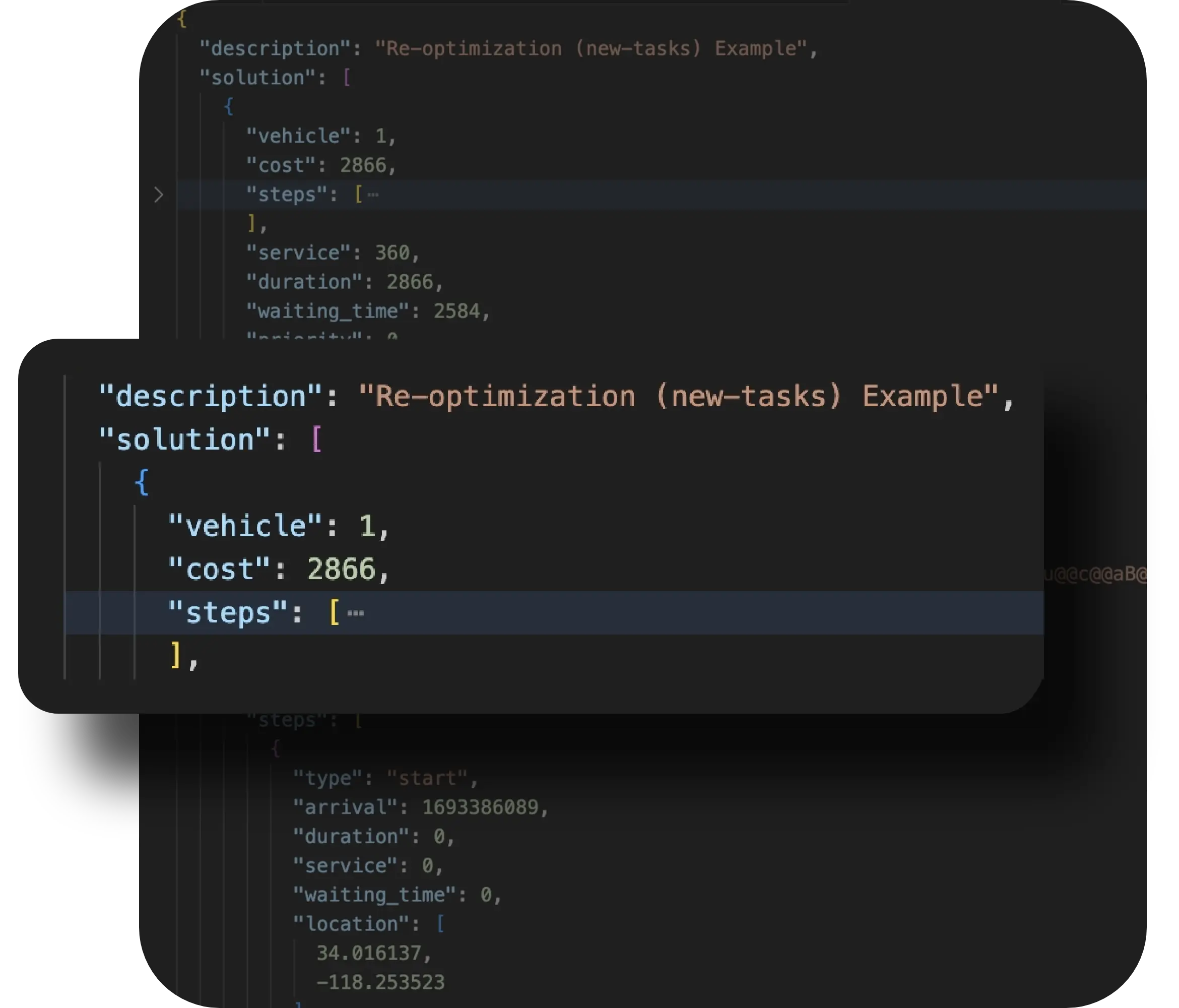

4. Dynamic Re‑Optimization for Late Returns

When a customer schedules a return after dispatched routes, the Re‑Optimization: New Tasks can insert these pickups into existing routes with minimal disruption. Similarly, Re‑Optimization: Unassigned Tasks can attempt to fit previously skipped returns when vehicle capacities or schedules change.

5. Consolidating Returns via Order Grouping & Zone Allocation

To reduce cost‑per‑stop:

- Order grouping batches multiple nearby pickups into one stop.

- Zone‑based allocations let you assign pickups in defined geofences to specific vehicles or crews (e.g., regional hubs).

6. Cost‑Aware Reverse‑Route Design

Returns can incur different cost structures (e.g., higher handling fees). You can:

- Supply a custom cost matrix (fuel, labor, carbon) so the solver minimizes true reverse‑leg cost.

- Define custom objectives (e.g., equal task distribution, maximize the number of pickups per route, minimize empty miles).

7. Scale & Performance

- Supports up to 10,000 tasks in one optimization request—enough for high‑volume return days

- Incorporates real‑time traffic for accurate ETAs on pickup windows

- Auto‑scales via multi‑tenant infrastructure; 99.99% SLA

Example of Reverse Logistics Request

The following example shows a complete working example of how the API can accommodate reverse logistics requests for multiple vehicles.

Imagine you’re managing a reverse logistics operation in Los Angeles where:

- You have 5 return pickups (customers returning items).

- You have 2 return shipments that need to go from customers → warehouse.

- You want to optimize how your drivers go about collecting all these returns and bringing them back to the depot.

- You’re using 2 trucks, each with their capabilities and capacities.

curl --location 'https://api.nextbillion.io/optimization/v2?key=' \

--header 'Content-Type: application/json' \

--data ' {

"description": "Test",

"locations":

{

"id": 1,

"location": ["34.083950,-118.318640","34.054927,-118.323726","34.075525,-118.361588","34.076350,-118.338519","34.090425,-118.338933","34.076646,-118.376969","34.094986,-118.300885","34.018780,-118.317919","33.996658,-118.261708","34.059244,-118.376969","34.057106,-118.361326"]

},

"jobs": [

{

"id": 1,

"location_index": 0,

"service": 120,

"pickup":[1],

"skills": [1],

"time_windows": [

[

1693393200,

1693394100

]

]

},

{

"id": 2,

"location_index": 1,

"service": 120,

"skills": [1],

"pickup":[1],

"time_windows": [

[

1693387800,

1693388700

]

]

},

{

"id": 3,

"location_index": 2,

"service": 120,

"pickup":[1],

"skills": [2],

"time_windows": [

[

1693396800,

1693397700

]

]

},

{

"id": 4,

"location_index": 3,

"service": 120,

"skills": [1],

"pickup":[1],

"time_windows": [

[

1693402200,

1693403100

]

]

},

{

"id": 5,

"location_index": 4,

"service": 120,

"skills": [2],

"pickup":[1],

"time_windows": [

[

1693400400,

1693401300

]

]

}

],

"shipments": [

{

"pickup":{

"description": "Shipment Pickup 1",

"id":1,

"location_index":5,

"time_windows":[[1693397400,1693397760]]

},

"delivery":{

"description": "Shipment Delivery 1",

"id":1,

"location_index":6,

"time_windows":[[1693400700,1693401300]]

},

"skills":[2,3],

"amount":[3]

},

{

"pickup":{

"description": "Shipment Pickup 2",

"id":2,

"location_index":7,

"time_windows":[[1693402200, 1693403100]]

},

"delivery":{

"description": "Shipment Delivery 2",

"id":2,

"location_index":8,

"time_windows":[[1693404900, 1693405800]]

},

"skills":[2,3],

"amount":[2]

}

],

"vehicles": [

{

"id": 1,

"start_index": 10,

"skills":[1],

"capacity":[10],

"time_window": [

1693382400,

1693411200

]

}, {

"id": 2,

"depot": 0,

"skills": [2,3],

"capacity":[10],

"time_window": [

1693382400,

1693411200

]

}

],

"depots": [

{

"description":"Depot 1",

"id":0,

"location_index":9

}

],

"options": {

"objective": {

"travel_cost": "distance"

},

"routing": {

"mode": "truck",

"truck_size": "210,210,320",

"truck_wieght": 12000,

"traffic_timestamp": 1693387800

}

}

}'

Let us break down each object for better understanding;

1. “locations”

This is your master list of GPS coordinates (lat/lng). Each location gets a position in the list (like an index in an array). You reference these positions later in jobs, shipments, vehicles, and depots.

2. “jobs” — These Are Return Pickups Only

These objects represent standalone pickup tasks — think of customers who are returning parcels but don’t require a paired delivery location.

Each job has:

- location_index: Where the pickup happens (based on the master list).

- pickup: The amount (e.g., 1 parcel).

- skills: Driver qualifications required.

- time_windows: When the pickup is allowed (Unix timestamps).

- service: How long the stop will take (in seconds).

In reverse logistics: These are ad hoc or one-way returns.

3. “shipments” — These Are Paired Return Tasks

Each shipment has:

- A pickup (e.g., customer’s home)

- A delivery (e.g., your warehouse or depot)

- time_windows for both stops.

- amount: Capacity load (e.g., 2 items)

- skills: Which vehicles/drivers can handle this

In reverse logistics: This is a typical return + drop-off use case.

Example: A customer returns a TV, which is then sent to a recycling center.

4. “vehicles” — These Are Your Trucks

Each vehicle has:

- id: Unique identifier

- start_index or depot: Where the route starts (from the location list)

- skills: What kind of tasks it can perform

- capacity: Maximum load it can carry

- time_window: Operating hours (in Unix time)

This defines how many reverse pickups/deliveries the truck can carry and when.

5. “depots” — Your Return Centers or Warehouses

This tells the system where your trucks begin or return to at the end. In this example, there’s one depot at location index 9.

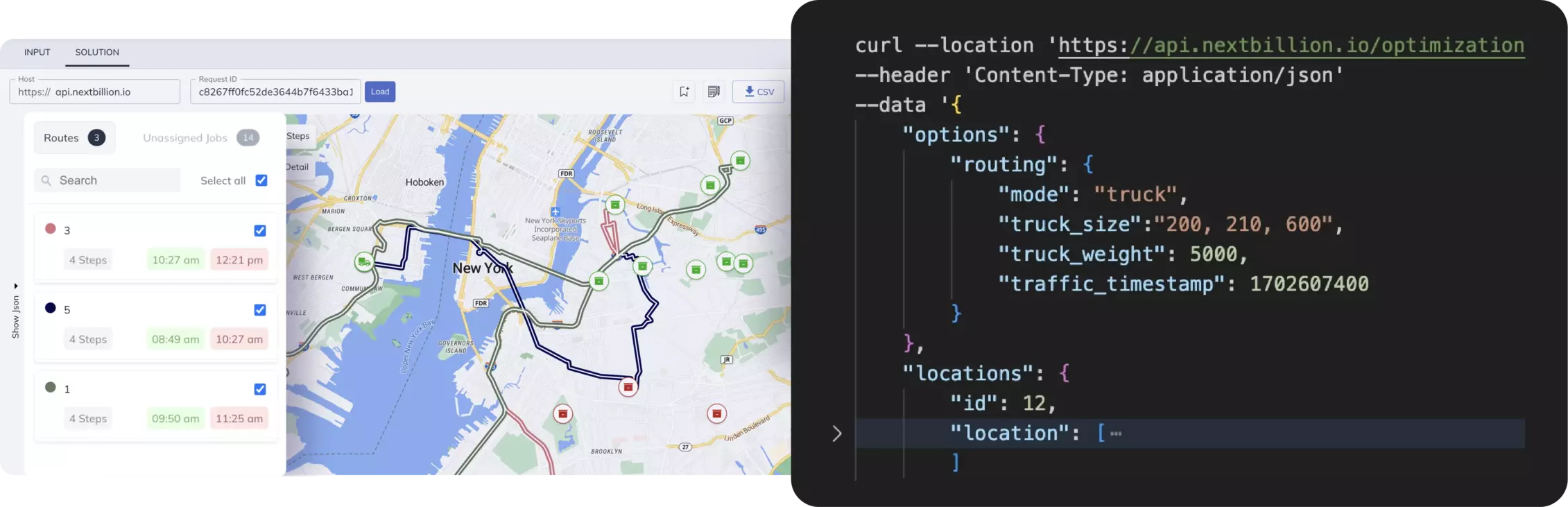

6. “options” — Optimization Settings

- “objective”: { “travel_cost”: “distance” }

→ Minimize total distance traveled (instead of time or other cost). - “routing” includes:

- Mode = “truck” (vs. car or bike)

- Truck size and weight

- traffic_timestamp: Optimization takes traffic at a specific time into account.

- Mode = “truck” (vs. car or bike)

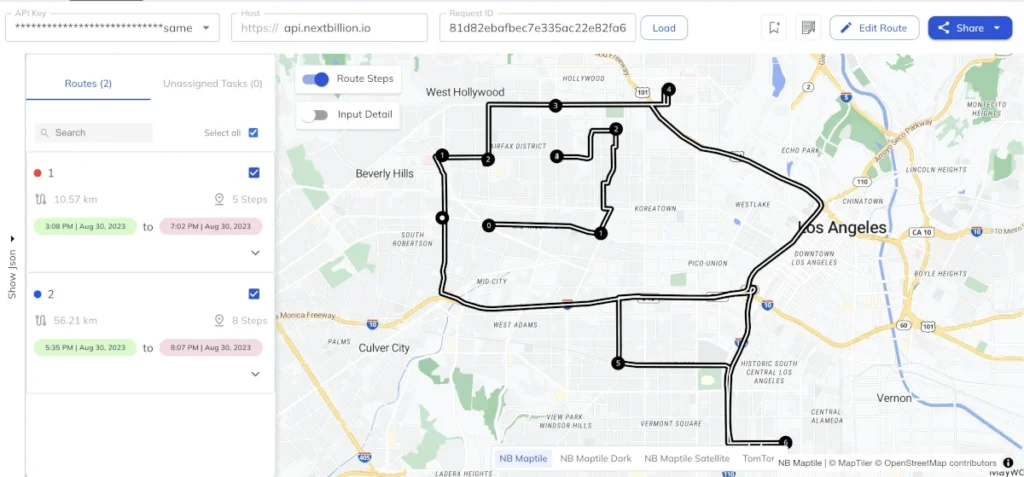

Once the example optimization request is submitted to the API using the POST method. The API returns a unique job ID, which can be used to fetch the optimized route result by submitting a GET request to the API, and the API returns the detailed route plan for your reverse logistics scenario.

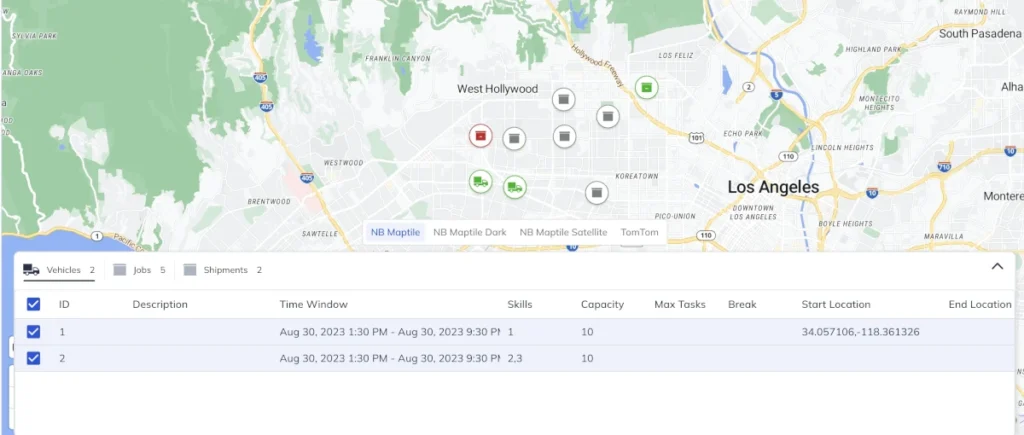

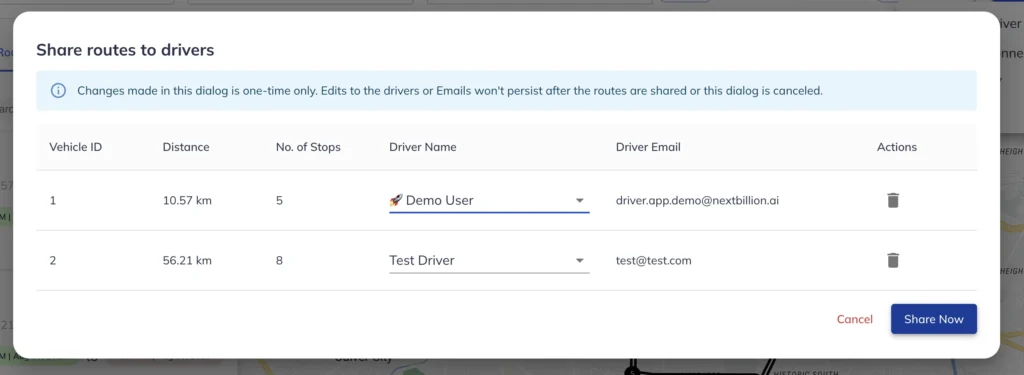

You can also use NextBillion.ai’s Route Planner App to visualize the route plan and dispatch the routes to the Driver App.

Why Choose NextBillion.ai for Reverse Logistics?

NextBillion.ai offers the following advantages for Reverse Logistics companies.

✅ AI-powered route optimization for reverse pickups.

✅ Reduce return costs and empty miles.

✅ Real-time visibility for customers and operations teams.

✅ Seamless API integration into your existing systems.

✅ Scalable and flexible for custom workflows.

Reverse logistics can get messy—returns, pickups, and drop-offs all happening at different times and places. It’s tough to manage without wasting time or fuel. NextBillion.ai helps simplify that. Its Route Optimization API lets you plan efficient pickup routes, track everything in real time, and combine returns with deliveries when it makes sense. It’s a practical way to keep your reverse logistics organized and running smoothly.

About Author

Shivangi Singh

Shivangi is a seasoned Technical Writer with a passion for simplifying technical concepts. With over 5 years of experience, she specializes in crafting clear and concise documentation for various technical products and platforms.