Table of Contents

What is Packing Cost?

As the name suggests, packing cost is the total cost needed to package a product. Everything that goes into making and delivering the package combines to form packaging costs. It is calculated based on four factors: packaging materials, packaging design, shipping costs, and lead time.

Factors Impacting Packing Cost

There are four factors based on which packaging costs are calculated:

- Packaging Material: The biggest consideration for the packaging cost is the material chosen for packing. Packaging materials can vary from the most expensive to the least costly in the market, but their selection should be based on the package to be delivered. These materials are generally made using lightweight plastic, thick cupboards, and even grass.

- Packaging Design: Packaging design comes into play when a product to be delivered needs special considerations like protection, insulation, or cleanliness. For example, specialized packaging is needed while delivering food products to preserve their quality.

- Shipping Costs: Shipping costs are the major contributor to packaging costs. Heavier, more complex packages will be more expensive to ship than lighter packages. Even the location of the packaging distributor will impact the packing cost.

- Lead Time: Indirectly, lead time also contributes to packaging costs. The more complex and customized the package, the more time it will take to prepare, deliver, and add to the cost.

How to Calculate Packing Cost?

It is pretty easy to calculate the packing cost. Below are some steps that will guide you in this process:

Step 1: Selecting material. The first and foremost step is to select the packaging material. The material must offer the best protection to your product and should fall within the budget range. The whole shipment of the product depends on this step; hence, the packaging material must be chosen wisely.

Step 2: Find suppliers. The next step is to find suppliers. Find at least 3-4 suppliers that specialize in shipping the category of product you chose. Along with this, choose the style and design that work best for your package.

Step 3: Calculate the shipping costs. The rates of suppliers can vary. The local suppliers offer the best shipping rates. Calculate the amount you can spend on shipping and choose the supplier accordingly.

Step 4: Compare bids. Choose the supplier that offers a great deal and is within your budget. The supplier must be trustworthy and have a good reputation. Sometimes, it is quite a hectic task to choose a suitable supplier.

Step 5: Consider value-adding perks. It is important to consider the factors other than pricing that make a package supplier more valuable, such as fast customer service, customer loyalty, a good reputation, etc.

How to Save Packing Costs?

Sometimes packaging costs are too expensive. To save packaging costs, the following steps can be taken:

Switch to Poly Bags: Instead of using heavy materials like cardboard or paper, use polybags to save on packaging costs. They are much lighter than any other material and have strong durability. It provides the strength and protection package needed during delivery without adding extra cost.

Order in Bulk: Another way to save on order and shipping costs is by ordering in large quantities. It is always beneficial to order in bulk rather than ordering one by one.

As discussed, packing costs are an integral part of the e-commerce logistics industry. It is important to both the shipper and the customer. By making a small reduction in size or shape, more products can fit in trucks, warehouses, and containers. Efficient packaging also reduces carbon footprints and helps to make shipping more eco-friendly. Hence, efficiency in packaging can significantly impact the supply chain.

We know that every business is different and we care about your unique needs.

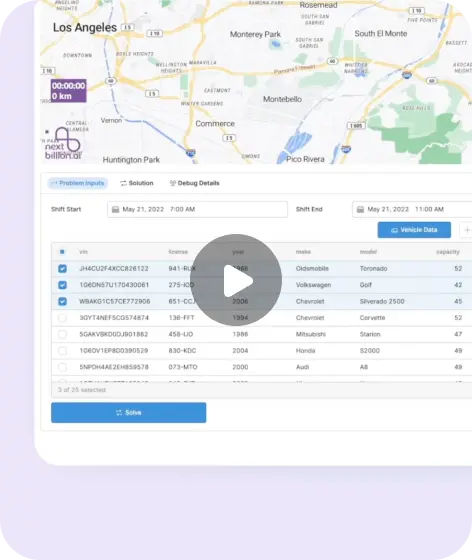

With NextBillion.ai’s Map API you get- Large Distance Matrix API with a Matrix size upto than 5000*5000

- Optimal routes with accurate ETAs

- Flexible navigation SDK that’s easy to integrate and ready to use for developers

- Quick and accurate location data

- Track and trace routes taken along with other map attributes

- Create custom tiles for your interactive maps. Personalized to fit your brand aesthetic.