Table of Contents

Logistics in the oil and gas industry is all about managing the transportation, storage, and distribution of petroleum products. It’s a complex process that keeps crude oil, natural gas, and refined products moving smoothly—from extraction sites all the way to end consumers.

Do you know that oil, which seems like a basic commodity, accounts for approximately 3% of GDP? Yes, and in fact, it is one of the most important commodities in the world. As of 2024, global oil consumption is all set to reach and even surpass the massive value of approximately 103.8 million barrels per day.

Ensuring the smooth flow of this vast supply requires a highly efficient logistics network. Advanced supply chain technologies—such as predictive analytics and real-time monitoring—are transforming oil and gas logistics, optimizing transportation, and reducing disruptions. Without these innovations, meeting the ever-growing energy demand would be nearly impossible.

In this article, we’ll break down the key components of logistics in the oil and gas industry, explore its biggest challenges, and examine how technology is reshaping operations. Let’s dive in!

Logistics in the Oil and Gas Industry: An Overview

The oil and gas industry is one of the most complex and vital sectors in the global economy. It powers homes, businesses, and industries across the globe. The core of the oil and gas industry is a complex logistics network that provides the seamless movement of resources. This network often relies on technologies like Geographic Information Systems (GIS) and Internet of Things (IoT)-enabled tracking. It further relies on digital twins for end-to-end operational visibility.

These technologies assist in the movement of everything ranging from crude oil extraction to refined products delivered to end consumers. Efficient logistics in the oil and gas industry is important for minimizing costs. It is also effective for providing operational continuity and addressing the unique challenges of this high-stakes sector.

Logistics in the oil and gas sector involves the strategic management of resources. It further includes transportation management, storage, and distribution of materials across vast and often remote geographies. Specialized vehicles equipped with IoT sensors, autonomous ships, and drones are utilized to deal with these challenging terrains.

Every link in the supply chain has a supreme role right from the drilling rigs of upstream operations to the pipelines and tankers of midstream logistics and the retail outlets of downstream activities.

Efficient logistics also assists in the reduction of mighty costs and also kicks off delays, and promises timely delivery. It helps in maintaining safety standards. Technologies like blockchain, when integrated into logistics, guarantee secure and transparent transactions across the supply chain. The sector’s complexity, when coupled with its dependence on international markets, makes robust logistics solutions a necessity to deal with operational hurdles.

Key Components of Logistics in Oil and Gas

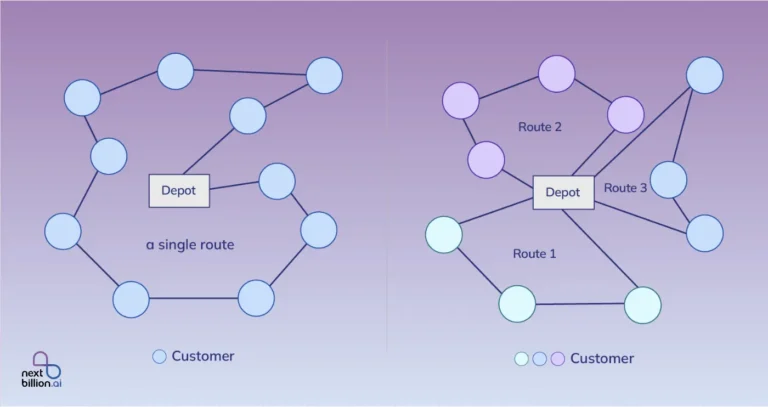

The oil and gas supply chain can be broadly classified into three segments, each with distinct logistical requirements:

1. Upstream Logistics

Upstream logistics covers the initial stages of the oil and gas supply chain, which mainly includes exploration and production. The transportation of heavy drilling equipment, rigs, and essential materials to remote onshore or offshore locations is a logistical challenge requiring precision planning and execution. Advanced route optimization software powered by AI guarantees minimal delays in transporting oversized loads to exploration sites.

Offshore logistics solutions, such as specialized vessels, helicopters, and floating storage units, are further essential for supporting drilling operations in remote waters. Marine navigation systems integrated with satellite communication technologies provide real-time updates, enhancing operational safety.

Onshore operations, on the other hand, rely on well-coordinated road and rail transportation networks. These well-knit networks help deliver supplies. Inefficient upstream logistics can result in costly delays, which further emphasizes the importance of robust transportation scheduling in the oil industry.

2. Midstream Logistics

Midstream logistics is the critical intermediary phase where crude oil and natural gas are transported from production sites to refineries. This phase relies heavily on pipelines, tankers, and storage facilities to ensure a steady flow of resources.

Pipeline logistics optimization systems equipped with IoT sensors facilitate early detection of leaks or flow disruptions and reduce the risk of environmental damage.

Shipping crude oil involves large tankers in the fleet that traverse international waters, necessitating compliance with stringent environmental and maritime regulations. Blockchain technology secures regulatory compliance by maintaining a tamper-proof record of shipping activities, cargo details, and emissions data.

Technologies such as IoT for oil and gas logistics enable real-time monitoring of pipeline, shipping, and fleet management operations, enhancing reliability and minimizing downtime.

3. Downstream Logistics

The downstream sector concentrates on refining crude oil and distributing finished products. These finished products include the ultimate distribution of gasoline, diesel, and petrochemicals to end-users. Last-mile delivery optimization algorithms play a vital role in ensuring timely product delivery to retail outlets and industrial clients.

Efficient downstream logistics requires a precise blend of warehousing, inventory management, and last-mile delivery systems. Automated inventory management systems powered by robotics and AI enable seamless operations, reduce manual errors, and ensure optimal stock levels.

Automated logistics solutions in warehousing help streamline operations. They also help with timely deliveries and reduce transportation costs.

Challenges in Oil and Gas Logistics

Let’s understand some of the common challenges in the logistics sector in oil and gas industry:

1. Complex Supply Chains and Remote Operation Sites

The logistics challenges in the oil and gas industry are seriously amplified by the complexity of the supply chains. Another challenge that evolves here is the remote locations in which the industry operates. Exploration and production sites are usually placed and settled in hard-to-reach and harsh environments. They are primarily located in regions like offshore oil rigs, arctic regions, and deserts, and sometimes in deep-sea locations.

Digital twins are being used to simulate supply chain operations, allowing companies to anticipate bottlenecks and optimize resource allocation for remote and challenging sites. Transporting materials, equipment, and personnel to these sites needs specialized transportation methods. These methods range from heavy-duty trucks, ships, and helicopters, to specialized barges. Heavy-lift helicopters like the Sikorsky S-92 or Antonov cargo planes are often employed for transporting oversized equipment to offshore or remote locations.

The remote nature of these locations, when combined with varying terrains, presents significant logistical hurdles. IoT-enabled sensors on transportation vehicles provide real-time data on route conditions, ensuring timely interventions for unexpected disruptions like adverse weather or roadblocks. These hurdles are nearly impossible to solve without meticulous planning and timely execution. Any delays in equipment delivery can halt production, which leads to costly downtime and potential losses.

Managing logistics in these challenging locations also mandates overcoming geographical and environmental barriers. Companies need to implement robust contingency plans to address potential disruptions. Advanced weather forecasting models powered by AI help logistics teams plan routes that minimize exposure to extreme conditions, such as storms or floods.

Coordinating a large number of suppliers and contractors spread across various regions adds another layer of complexity. Blockchain-based supply chain management systems ensure real-time communication between multiple stakeholders, reducing inefficiencies.

2. High Transportation Costs and Stringent Regulations

The transportation of oil and gas resources, especially across long distances and remote areas, poses significant costs. These expenses include fuel costs, labor, maintenance of specialized vehicles and vessels, and insurance. Route optimization software or APIs can help minimize fuel consumption by identifying the most efficient delivery routes.

The hazardous nature of the materials also adds to the complexity. It requires additional safety measures and regulatory compliance. Moreover, governments and international bodies impose stringent regulations on the transportation of hazardous materials. Compliance tracking tools integrated with IoT systems monitor vehicle adherence can ensure compliance with HAZMAT protocols.

It can increase operational costs due to the need for specialized vehicles, equipment, and trained personnel. Compliance with safety regulations and environmental laws requires substantial investments in infrastructure and operational practices. Oil and gas companies are adopting telematics systems that automate compliance reporting. This is helping to reduce manual oversight and associated costs. However, it adds to the overall cost burden for companies operating in the energy sector.

3. Managing Volatile Market Demands and Geopolitical Risks

The oil and gas industry is subject to market fluctuations, influenced by global demand shifts and geopolitical events. This volatility leads to sudden and drastic changes in transportation and distribution demand, which, in turn, affects logistics procedures. Predictive analytics powered by machine learning models can help in predicting and forecasting demand fluctuations, helping companies to manage the supply chain operations proactively.

Geopolitical risks such as trade restrictions and sanctions are major disruptions. Conflicts can also degrade shipping and freight in the energy industry. These risks are insane as they cause delays or the complete rerouting of shipments. Blockchain-based logistics platforms ensure alternative supply routes can be quickly identified. They help maintain continuity despite geopolitical challenges.

4. Environmental and Safety Compliance in Logistics Operations

Logistics in the oil and gas industry are also subject to a wide range of environmental and safety regulations. Besides, ensuring compliance with all these stringent regulations is non-negotiable. Spills and accidents are not just fatal economically; they are disasters to our sensitive environment, too.

AI-powered monitoring systems with IoT-enabled sensors track pipeline integrity and tanker conditions in real time, reducing the likelihood of spills and accidents.

Safety failures during transportation can also lead to catastrophic environmental damage, influence operations by imposing serious financial penalties, and cause real damage to a company’s reputation. Guaranteeing that all logistics operations meet safety standards while fighting for and conserving environmental impact is a consistent challenge.

Automated compliance tools integrated with enterprise resource planning (ERP) systems ensure adherence to international environmental standards, such as ISO 14001.

Companies are also under pressure to adopt greener practices and fix plus improvise their energy transportation safety protocols. These improved protocols will help them meet regulatory demands and consumer expectations. Green logistics solutions, such as hydrogen-powered trucks and renewable energy-powered hubs, are being adopted to lower the environmental impact of transportation.

Environmental considerations further include reducing emissions and optimizing routes to minimize fuel consumption. They also include using cleaner transportation methods. AI-driven optimization tools analyze real-time traffic and route conditions by identifying the most fuel-efficient paths.

Technology Integration in Logistics

The oil and gas industry relies on complex logistics networks to transport crude oil, refined products, and equipment across vast distances. Technology plays a crucial role in streamlining these operations.

1. Implementation of IoT for Real-Time Tracking and Monitoring

The Internet of Things (IoT) has literally revamped logistics by enabling real-time tracking of equipment. It helps trace shipments and inventory. Sensors installed in pipelines, trucks, and storage tanks deliver critical data on flow rates and temperatures. For instance, telematics provide real-time data about the vehicle’s health in the fleet. When route optimization software is integrated with a telematics system, like Samsara, it can help in planning the routes for vehicles appropriately.

They also curate and share data linked to potential leaks and eventually help ensure timely interventions. For example, IoT-enabled systems can monitor a shipment’s location and condition. This further improves visibility across the supply chain and ensures real-time tracking in energy logistics.

2. Route Optimization

Artificial intelligence (AI) and predictive analytics are literally the game-changers for fleet management in the oil industry. AI-powered route optimization technologies, like NextBilion.ai’s, optimizes routes by analyzing historical data and live inputs. Some tools can also help to predict demand surges and identify potential risks by helping companies save time and costs.

3. Automation in Warehouse and Inventory Management

Automation enriches efficiency in inventory management in the oil industry with remarkable precision. It also allows and even assists companies in maintaining optimal stock levels and reducing down manual errors. Robotics and automated systems promise faster processing times in warehouses. On the other hand, there are smart inventory solutions that help predict replenishment necessities.

4. Blockchain for Transparency in Supply Chain Operations

Blockchain technology introduces unparalleled transparency to logistics operations. Blockchain provides the authenticity of shipments by recording every transaction in a decentralised ledger. It also helps track compliance and level up trust among stakeholders. It is super useful for fuel supply chain optimization, where transparency has the most crucial role to play.

Integrating these technologies allows oil and gas companies to increase efficiency, lower costs, and enhance safety.

Supply Chain Management

Oil and gas supply chains are highly complex, involving upstream, midstream, and downstream operations. Managing this efficiently requires robust planning and execution strategies.

- Inventory and Demand Forecasting: Predicting demand fluctuations ensures the right amount of product is available without overstocking or shortages. AI-driven forecasting tools help reduce waste and optimize inventory levels.

- Multi-Modal Transport Management: Crude oil and refined products move via pipelines, tankers, rail, and trucks. Coordinating these modes requires advanced logistics solutions to avoid bottlenecks and delays.

- Supplier and Vendor Coordination: A connected network of suppliers, refineries, and distributors ensures smooth operations. Digital platforms facilitate real-time communication, reducing delays in decision-making.

- Regulatory Compliance: Staying compliant with international and local transport regulations prevents legal issues and financial penalties. Route planning software, like NextBillion.ai’s API, helps logistics teams account for road restrictions and safety regulations in different regions.

A well-optimized supply chain minimizes disruptions, improves resource allocation, and ensures timely deliveries.

Safety and Compliance

Safety is a top priority in oil and gas logistics due to the hazardous nature of the materials being transported. Companies must comply with strict regulations to prevent accidents, environmental damage, and legal issues.

- HOS Compliance: Drivers must adhere to Hours of Service (HOS) regulations to prevent fatigue-related incidents. Route planning tools can factor in mandatory rest breaks and driving limits.

- Hazmat Transport Regulations: Transporting hazardous materials requires specialized handling and route planning. Smart routing software ensures compliance with restricted zones and designated hazmat routes.

- Real-Time Monitoring: GPS tracking and telematics help monitor speed, braking patterns, and route deviations, allowing companies to enforce safety protocols.

- Emergency Response Planning: AI-powered risk assessment tools analyze potential hazards and suggest alternate routes or contingency plans in case of disruptions.

By prioritizing safety and compliance, logistics teams can minimize risks, avoid fines, and ensure smooth transportation of critical resources.

You can literally call optimised logistics the backbone or spine of operational success in the oil and gas industry. Yes, because companies can get numerous benefits just by leveraging advanced technologies and strategic planning. This includes cost savings and improved safety. It also includes enhanced supply chain visibility and reduced downtime. Let’s immerse deeper into each of these advantages:

1. Cost Savings Through Efficient Transportation and Storage

Efficient logistics practices can significantly lower the costs associated with transportation and storage in the oil and gas sector. By optimizing routes, consolidating shipments, and utilising modern tracking tools, companies can reduce fuel consumption, vehicle wear and tear, and unnecessary delays.

For example, integrating route optimization APIs allows logistics managers to schedule the shortest and most efficient paths for vehicles.

Similarly, smart storage systems ensure that inventory levels are managed to avoid overstocking or shortages. This smart feature reduces warehouse operational costs. These measures help cut those annoying expenses and also enable companies to maximize the use of their assets, creating a leaner and more cost-effective supply chain.

2. Improved Safety and Reduced Environmental Impact

Safety and environmental responsibility are necessary in oil and gas logistics due to the hazardous nature of the materials being transported. Optimized logistics practices prioritise safety protocols and ensure that accidents, spills, and emissions are either prevented or minimized to a great extent.

Technologies like IoT and blockchain improve compliance with energy transportation safety protocols. They do this by providing real-time monitoring of pipelines, shipping vessels, and vehicles. Sensors can detect leaks or temperature changes, and they readily allow for immediate intervention to prevent accidents.

In terms of environmental impact, optimised logistics ameliorates the carbon footprint. Well, they execute this by minimising redundant transportation and adopting greener alternatives such as electric or hybrid vehicles. Also, fuel-efficient transportation routes and warehousing powered by renewable energy contribute to an organized, sustainable supply chain. Such measures connect with global environmental standards while safeguaring and nurturing the company’s reputation.

3. Enriched Supply Chain Visibility and Coordination

Visibility across the supply chain is vital for efficient operations in the oil and gas industry. Optimized logistics enables real-time tracking of shipments.

Advanced platforms that combine real-time tracking in energy logistics ensure that all participants in the supply chain, from suppliers to distribution teams, are connected and informed about the status of operations. This reduces the risk of miscommunication or delays, which are mainly caused by a lack of transparency.

Collaborative tools enhance coordination between various departments and external partners. They assist in streamlining processes and improving accountability. Enhanced visibility is there to enable faster resolution of issues such as shipment delays or inventory discrepancies. All this combines and ensures smooth and hassle-free operations.

4. Decreased Downtime and Faster Response to Operational Needs

Downtime is one of the most costly challenges in the oil and gas sector. This hefty challenge directly affects production levels and revenue. Optimised logistics minimises the likelihood of delays by providing the timely delivery of materials, equipment, and products.

Predictive analytics, powered by AI, plays a fundamental role in identifying potential disruptions in the supply chain before they occur. For example, if a delay is expected due to weather conditions, road closures, or port congestion, logistics teams can proactively adjust routes and expedite shipments to prevent downtime.

Moreover, advanced tools such as digital twins and IoT-enabled systems support quick responses to operational requirements. This impeccable feature ensures that maintenance crews and spare parts reach their destinations promptly. This proficiency in responding dynamically levels up operational efficiency and condenses down costly interruptions in production.

Future Trends in Oil and Gas Logistics

The oil and gas logistics landscape is evolving with advancements in technology and shifts in global energy demand. Key trends shaping the future include:

- AI-Driven Logistics Optimization: Machine learning algorithms will enhance predictive maintenance, route optimization, and supply chain forecasting, reducing inefficiencies.

- Sustainability Initiatives: Companies are investing in alternative fuels, carbon tracking, and emissions reduction strategies to align with global sustainability goals.

- Autonomous and Electric Vehicles: The adoption of electric trucks and autonomous vehicles will improve efficiency and reduce environmental impact.

- Edge Computing and IoT Integration: Real-time data processing at the edge will improve response times for route changes, fleet tracking, and safety monitoring.

- Greater Adoption of API-Driven Solutions: Logistics teams will rely on APIs like NextBillion.ai’s to customize route planning, integrate multiple data sources, and streamline last-mile deliveries.

These innovations will reshape how oil and gas logistics operate, making them more efficient, sustainable, and adaptable to industry demands.

Conclusion

The oil and gas industry’s reliance on a robust logistics framework highlights the importance of innovation and technology in streamlining operations. Companies that adopt advanced logistics solutions and prioritise sustainability will definitely lead the way in efficiency and safety. Route optimization software can make logistics more efficient and profitable.

Route optimization software considers several parameters to predict the best and optimal routes such that vehicles reach their destination by covering shorter routes. For instance, NextBillion.ai’s route optimization software uses 50+ constraints to create ready-to-use routes.

Besides, it offers an entire fleet management solution that includes all the essential tools, including route optimization, navigation, and analytics, to streamline operations. Book a demo today to learn how it can help to simplify your logistics process.

About Author

Bhavisha Bhatia

Bhavisha Bhatia is a Computer Science graduate with a passion for writing technical blogs that make complex technical concepts engaging and easy to understand. She is intrigued by the technological developments shaping the course of the world and the beautiful nature around us.